Description

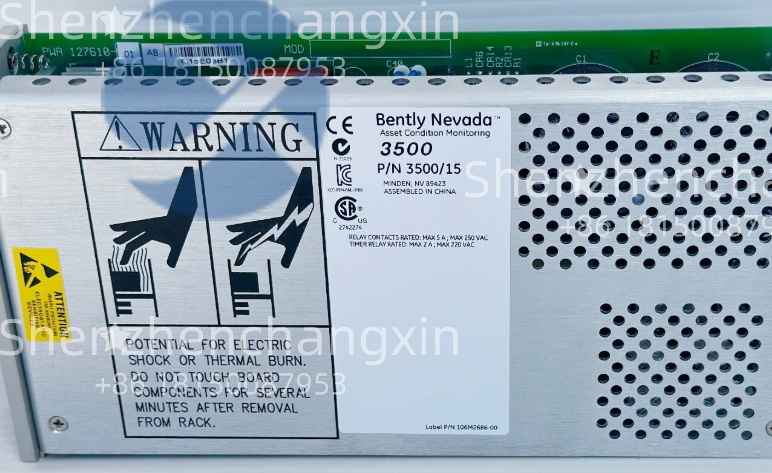

The Bently Nevada 3500/94 (part number 145988) is a high-performance, redundant communication gateway module in the 3500 Machinery Protection System—a globally trusted platform for continuous monitoring and protection of critical rotating equipment such as turbines, compressors, pumps, and generators. Designed to bridge the 3500 system with plant-wide control and asset management networks, the 3500/94 supports multiple industrial protocols, including Modbus, Bently Nevada’s proprietary TDIU (Time Division Interface Unit) protocol, and optional Ethernet/IP or PROFIBUS DP, enabling seamless integration into DCS, SCADA, and IIoT ecosystems.

With dual independent communication channels and hot-swap capability, the 3500/94 ensures uninterrupted data flow even during maintenance or network faults—making it indispensable in power plants, oil & gas facilities, and heavy industry where machinery downtime carries severe operational and safety consequences.

Application Scenarios

At a combined-cycle power plant in Southeast Asia, operators struggled to correlate vibration alarms from the Bently Nevada 3500 rack with process data in their ABB 800xA DCS. The legacy serial interface caused data latency and occasional dropouts during peak load transitions. The plant upgraded to the 3500/94 (145988), configuring one port for Modbus TCP to the DCS and the second for TDIU to the local machinery historian. Within days, real-time vibration trends appeared alongside steam pressure and temperature in operator graphics. During a bearing degradation event on a boiler feed pump, early warning from the 3500/94-enabled analytics allowed a planned shutdown—avoiding a $ 2M catastrophic failure. This case exemplifies how the 3500/94 transforms raw sensor data into actionable operational intelligence.

Technical Principles and Innovative Values

Innovation Point 1: Protocol Agnosticism with Dual-Channel Flexibility

Each of the two ports on the 3500/94 can be independently configured—for example, Port 1 for Modbus TCP to DCS, Port 2 for TDIU to local historian. This eliminates the need for external protocol converters and reduces single points of failure.

Innovation Point 2: Seamless Integration with Asset Management Ecosystems

The 3500/94 enables direct data streaming to Emerson AMS Machinery Manager, Baker Hughes System 1. or cloud platforms like Bently Nevada Orbit™, supporting predictive maintenance and ISO 13374-compliant MIMOSA data models.

Innovation Point 3: Deterministic Data Delivery for Protection Loops

Unlike generic gateways, the 3500/94 prioritizes alarm and trip-status data, ensuring < 100 ms delivery to safety systems—critical for SIL-rated turbine shutdown sequences.

Innovation Point 4: Cyber-Secure Legacy Modernization

With configurable IP filtering, password protection, and optional TLS encryption (in newer firmware), the 3500/94 helps legacy 3500 systems comply with NERC CIP and IEC 62443 without replacing entire racks.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: