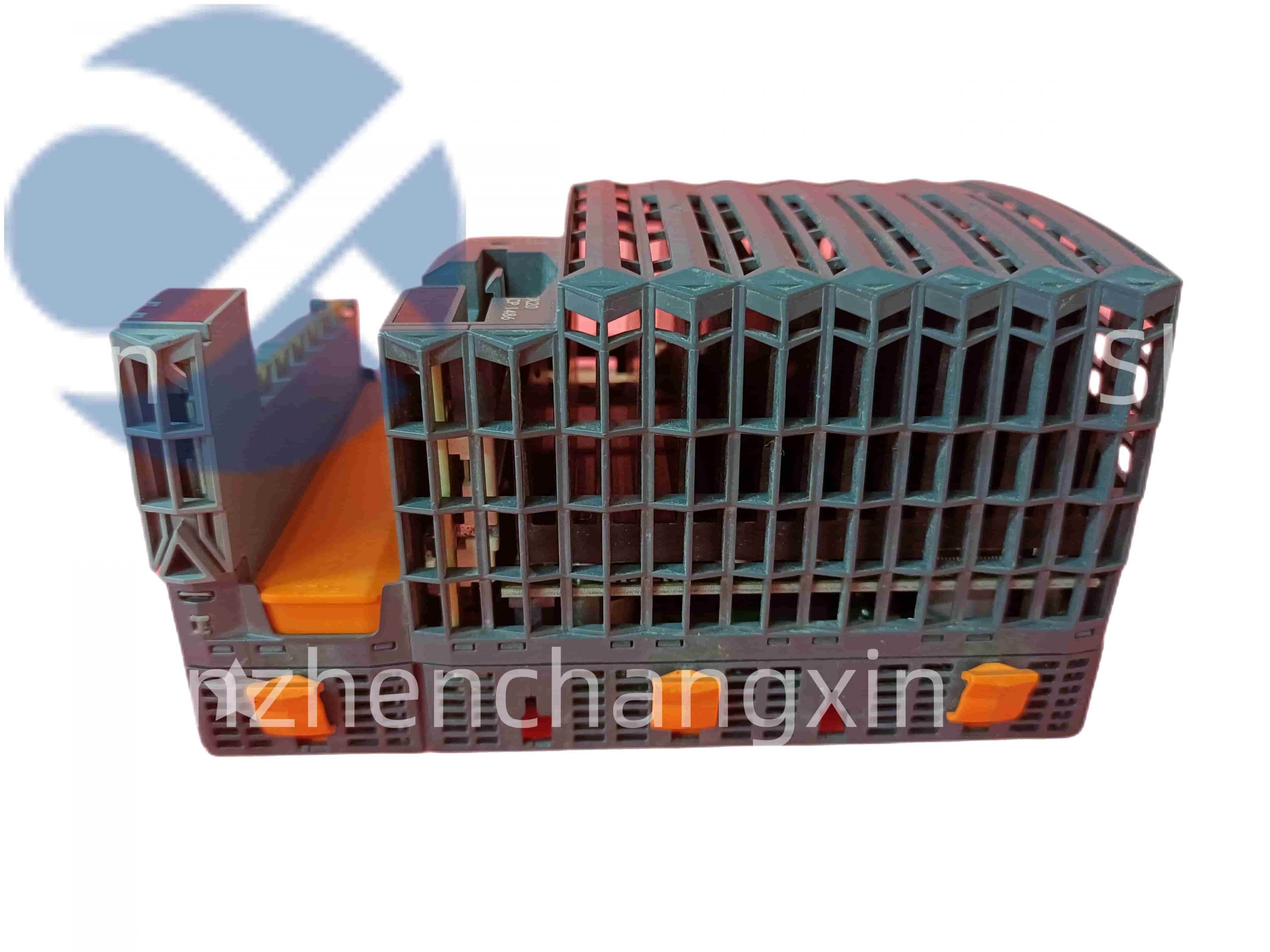

Product Description

The B&R X20CP1486 is a high-performance CPU (Central Processing Unit) module manufactured by B&R Automation (a member of the ABB Group), serving as the core controller within the modular X20 system. This powerful module is designed for demanding automation tasks, combining robust processing capabilities with versatile connectivity to manage complex machine control, motion control, and data handling applications efficiently in industrial environments.

Key Parameters:

Processor: PowerPC architecture

Program Memory: 2 MB

Data Memory: 1 MB

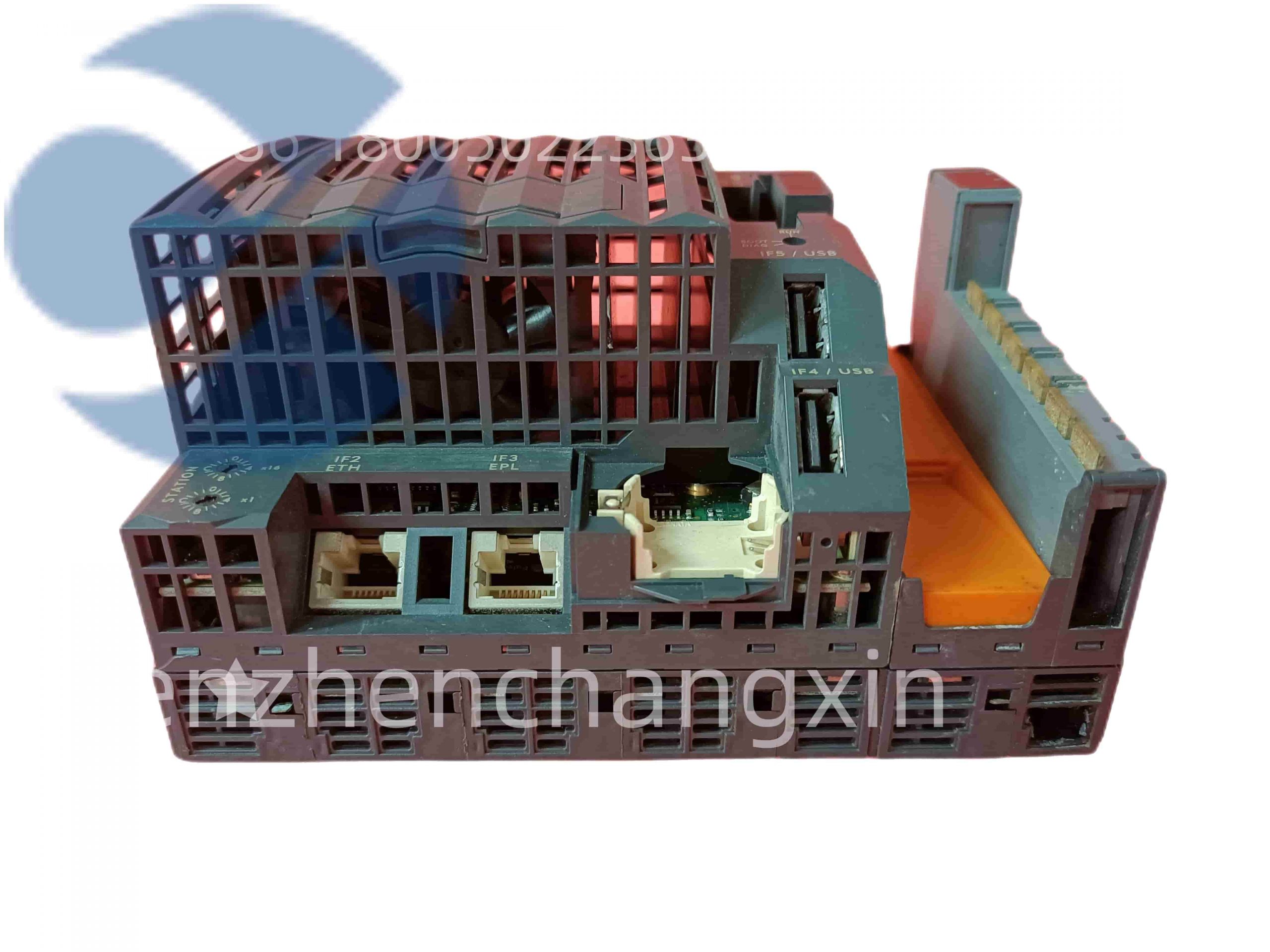

Integrated Interfaces: Ethernet, RS232. USB

Power Supply: 24 V DC

Technical Specifications

Product Overview

The B&R X20CP1486 is the computational heart of an X20 station, a modular and compact PLC system known for its flexibility. It executes the user program written in Automation Studio, B&R’s integrated engineering environment, handling logic, arithmetic, communication, and specialized functions like motion control. The module connects to the system’s I/O modules—digital, analog, specialty—via the high-speed X2X Link backplane bus, ensuring deterministic data exchange. Its integrated Ethernet port serves as the primary network node for connecting to HMI panels, higher-level SCADA systems, or other controllers, making the X20CP1486 a central hub for data and control flow in mid-range to high-end automation projects.

Main Features and Advantages

Powerful Processing Core: At the heart of the B&R X20CP1486 lies a PowerPC-based processor, balancing performance and determinism for real-time control tasks. With 2 MB of program memory and 1 MB of data memory, it accommodates complex control algorithms and handles substantial data volumes, which is essential for applications involving extensive recipe management or data logging.

Integrated Connectivity and System Integration: The module comes equipped with essential interfaces: an Ethernet port for network communication, an RS232 port for legacy device connection or commissioning, and a USB service port. This eliminates the need for separate communication modules for basic connectivity, simplifying cabinet layout and reducing costs. Its seamless integration within the X20 system via the X2X Link backplane provides high-speed, synchronized data exchange with all local I/O modules.

Motion Control Capability: A key advantage of the X20CP1486 is its native support for motion control tasks. It can directly manage several servo and stepper drives via the POWERLINK network (using a X20IF1064-2 interface module), enabling precise coordinated motion for applications like pick-and-place, flying saws, or conveyor synchronization, all within a single, unified controller platform.

Robust and Programmable Platform: Engineered for the factory floor, the X20CP1486 operates reliably within standard industrial temperature ranges. Programming is done in B&R’s Automation Studio, which supports all IEC 61131-3 languages (Ladder Diagram, Structured Text, etc.), C, and even MATLAB®/Simulink® for advanced control strategies, offering tremendous flexibility for engineers.

The B&R X20CP1486 CPU module delivers robust performance for complex automation tasks within the modular X20 system. Its PowerPC processor and integrated memory handle demanding logic and data processing, while built-in Ethernet, RS232. and USB ports provide essential connectivity. A significant strength is its ability to execute motion control tasks, managing multiple axes via POWERLINK for integrated machine control. Programmed through the comprehensive Automation Studio suite, it offers engineers a powerful and flexible platform for implementing everything from basic logic to advanced algorithmic control in a reliable industrial package.

Application Fields

The B&R X20CP1486 is ideally suited for sophisticated machine automation and mid-range process control applications where processing power, connectivity, and motion control are required.

In packaging machinery, such as high-speed cartoners or fillers, the X20CP1486 excels. It handles the complex sequential logic for product handling, coordinates multiple servo axes for precise positioning via integrated motion control, and communicates with rotary encoders and vision systems. Its processing power manages recipe changes on-the-fly and its Ethernet port feeds production data to a plant-wide MES.

For plastic injection molding machines, this CPU manages the entire cycle: controlling the temperature of multiple zones via PID loops on analog I/O, executing the precise movement profiles for the injection unit and mold clamp using its motion capabilities, and monitoring pressure and position for quality assurance. The deterministic performance ensures repeatable cycle times.

In material handling systems, like automated storage and retrieval systems (AS/RS) or complex conveyors, the X20CP1486 coordinates the movement of carriers, manages barcode reading stations, and interfaces with a warehouse management system. Its ability to handle network communication and substantial program logic makes it a central controller for such interconnected systems.

Related Product Combination Solutions

The B&R X20CP1486 is designed to work with a wide array of X20 system modules to build a complete control station:

X20BB82: A standard 8-slot base module that provides the physical backplane and power distribution for the X20CP1486 CPU and other I/O modules.

X20IF1064-2: A 2-port POWERLINK interface module. This is essential for the X20CP1486 to connect to and control B&R ACOPOS servo drives for motion control applications.

X20DC1036: A digital input module (24V DC, 32 channels). Used to connect sensors, buttons, and limit switches to the system controlled by the X20CP1486.

X20DO9322: A digital output module (24V DC, 32 channels, 0.5A). Used to control actuators, valves, and indicators commanded by the X20CP1486.

X20AT2222: A 2-channel analog input module (voltage/current). Allows the X20CP1486 to read signals from analog sensors like temperature transmitters or pressure sensors.

X20PS9400: A system power supply module that provides stabilized 24V DC power to the entire X20 station, including the X20CP1486 CPU.

Installation, Maintenance, and Support

Installation and Commissioning: The B&R X20CP1486 is designed for straightforward integration. It plugs securely into a base module (like the X20BB82), which is mounted on a DIN rail. Electrical installation involves connecting the 24V DC system power to the base module’s terminals. Commissioning is performed using B&R’s Automation Studio software on a PC. The engineer connects to the CPU via the Ethernet or USB port, downloads the compiled control program, and configures network settings and parameters. The modular design allows for easy expansion by adding more I/O or interface modules to the same base unit as needed.

Maintenance and Diagnostics: Routine maintenance is minimal, primarily involving keeping the unit free from excessive dust and ensuring adequate ventilation. The X20CP1486 features status LEDs that provide immediate visual feedback on operating state, errors, and network activity. For in-depth diagnostics, Automation Studio provides comprehensive tools to monitor CPU load, memory usage, scan times, and detailed diagnostic buffers to trace faults. Firmware updates can be performed online to add features or improvements. In the rare event of a hardware failure, the module can be replaced by a new unit, and the program downloaded again, minimizing downtime.

Technical Support and Lifecycle: B&R provides extensive technical support for the X20CP1486. including detailed documentation, application examples, and direct engineering support. The X20 platform is known for its long-term availability, ensuring continuity for machines with multi-decade lifecycles. Spare parts are readily available through authorized distributors. For optimal support in sourcing, technical consultation, and after-sales service for the B&R X20CP1486 and the entire X20 system, you can rely on experienced partners.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: