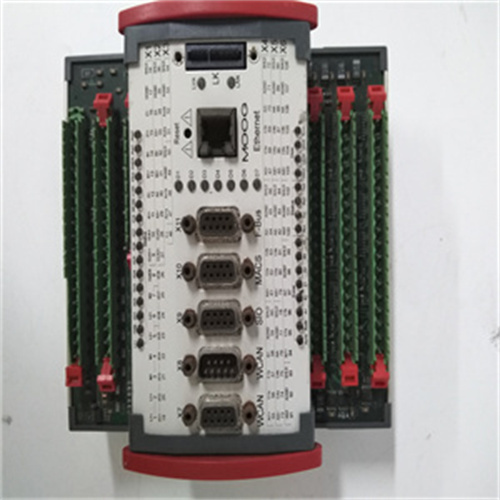

Description

TheMOOG D136-001-007 is a high-performance digital servo drive or control module manufactured by Moog Inc., a global leader in precision motion control systems. This component functions as the intelligent power and control interface within a servo system, responsible for executing motion profiles, regulating current/torque, and providing closed-loop control for electric servo motors. It is engineered for demanding applications requiring exceptional accuracy, dynamic response, and reliability in industrial automation, test equipment, and aerospace systems.

Application Scenarios

Within a state-of-the-art flight simulator, a six-degree-of-freedom motion platform must recreate the precise, violent vibrations and nuanced tilts of actual flight. The hydraulic actuators driving this massive platform are controlled by high-bandwidth servo valves, which in turn are commanded by a high-performance drive. TheMOOG D136-001-007 serves as this critical drive. It receives a precise motion command from the host computer hundreds of times per second. Internally, it runs sophisticated control algorithms, comparing the command to real-time feedback from a resolver or LVDT on the actuator. It then calculates and delivers the exact electrical signal needed to position the servo valve spool, controlling oil flow to move the multi-ton platform with millimeter and millisecond precision. In this role, the drive’s reliability and flawless performance are non-negotiable; any lag or fault breaks the simulation illusion and risks safety. For the maintenance team, theD136-001-007 is a core, system-critical component whose failure necessitates immediate, expert-level intervention to restore multi-million dollar training assets.

Parameter

Main Parameters

Value/Description

Product Model

D136-001-007

Manufacturer

Moog Inc.

Product Category

Digital Servo Drive / Servo Amplifier

Input Power

Likely Three-Phase AC (e.g., 480VAC) or High-Voltage DC.Provides the main power for the amplifier and motor.

Output Power

Designed to drive brushless servo motors with specific current/voltage ratings.Defines the torque and speed capability of the connected motor.

Control Modes

Torque, Velocity, Position (Cyclic Synchronous modes typical).Determines how the drive regulates the motor (force, speed, or angle).

Feedback Interface

Supports high-resolution feedback devices: Resolver, Sin/Cos Encoder, EnDat.Essential for precise closed-loop control.

Command Interface

Analog ±10V, Digital (Pulse & Direction), Fieldbus (e.g., SERCOS, EtherCAT, PROFINET).Accepts commands from a PLC or motion controller.

Communication

Integrated fieldbus interface for parameterization, diagnostics, and networked control.Enables integration into modern automation architectures.

Protection Features

Over-current, Over-voltage, Over-temperature, Short-circuit, Feedback loss.Safeguards the drive and motor from damage.

Form Factor

Modular chassis or standalone unit designed for panel or rack mounting.

Technical Principles and Innovative Values

TheMOOG D136-001-007 encapsulates Moog’s core competency in high-dynamics, deterministic motion control, translating advanced control theory into robust hardware.

Innovation Point 1: Advanced Digital Signal Processing for Ultimate Performance. The drive’s core is a high-speed digital signal processor (DSP) running Moog’s proprietary control algorithms. Unlike simple proportional–integral–derivative loops, these algorithms often incorporate advanced techniques like feedforward control, notch filtering, and adaptive tuning to counteract mechanical resonances and nonlinearities in the load. This allows theD136-001-007 to achieve exceptionally high bandwidth and stability, enabling the precise, jitter-free motion required for applications like optical alignment or vibration testing.

Innovation Point 2: High-Fidelity Power Stage with Intelligent Switching. The power section uses advanced Insulated-Gate Bipolar Transistor technology with optimized gate drive and switching patterns to minimize electrical noise and switching losses. This results in higher efficiency, reduced thermal stress, and cleaner power delivery to the motor, which translates to smoother motion, especially at low speeds, and extended component life. The drive’s ability to deliver high peak currents for rapid acceleration while maintaining precise control at low speeds is a direct result of this sophisticated power stage design.

Innovation Point 3: Seamless Multi-Axis Synchronization via High-Speed Networks. A key innovation is its integration into deterministic motion networks. Using a real-time Ethernet protocol like EtherCAT or SERCOS, multipleD136-001-007 drives can be synchronized with sub-microsecond jitter. This allows for perfect coordination in complex multi-axis systems, such as a robotic arm or a CNC machine, where the path accuracy depends on the perfectly timed movement of all axes. The drive handles the low-level current loop control locally, offloading the central controller and enabling vastly more complex and coordinated motion.

Innovation Point 4: Comprehensive Integrated Diagnostics and Condition Monitoring. The drive goes beyond basic fault reporting. It continuously monitors a vast array of internal parameters: heatsink temperature, DC bus ripple, IGBT junction temperature estimates, and feedback signal quality. This data can be trended to predict maintenance needs, such as a failing cooling fan or degrading electrolytic capacitors in the DC bus, before they cause a failure. This shift from reactive to predictive maintenance, enabled by the intelligence of theD136-001-007, significantly increases system uptime.

Application Cases and Industry Value

Case Study: Precision Gantry System in Semiconductor Wafer Handling

A manufacturer of semiconductor processing equipment uses a high-speed, cleanroom gantry robot to transfer wafers between process chambers. The robot’s X and Y axes are driven by high-acceleration linear motors controlled byMOOG D136-001-007 drives. The requirement is for “stop-on-a-dime” accuracy at the micron level to align wafers with pins, and ultra-smooth motion to prevent particle generation. The drives’ advanced tuning software allowed engineers to implement sophisticated vibration damping filters, eliminating subtle mechanical oscillations that previous drives could not control. The result was a 15% increase in throughput due to faster, more stable moves and a dramatic reduction in misalignment errors. The lead systems engineer stated, “TheD136-001-007 gave us the control bandwidth and tuning granularity we needed. Its stability at high speed and precision at low speed were the differentiating factors in meeting our aggressive cycle time and accuracy specs.”

Case Study: Hydraulic Test Stand for Aircraft Component Validation

An aerospace testing lab operates a multi-actuator rig to apply complex, simulated flight loads to aircraft landing gear components. The system uses electro-hydraulic servo valves controlled byMOOG D136-001-007 drives. The drives must faithfully reproduce high-frequency spectral content from real flight data. Their high update rate and precise current control ensure the servo valves respond accurately to the demanding command signal. During a critical test, the drive’s built-in diagnostic flagged a gradually increasing current deviation in one axis. Investigation revealed a slowly leaking seal in the hydraulic system, not a drive fault. The predictive warning allowed the test to be paused and the seal replaced before a major hydraulic leak contaminated the test article. The test lab manager noted, “The intelligence in theD136-001-007 drives protects our capital. We’re not just controlling force; we’re monitoring the entire actuation system’s health.”

Related Product Combination Solutions

TheMOOG D136-001-007 operates within a complete motion control ecosystem. Key complementary components include:

Moog Servo Motors/Actuators: Brushless servo motors (rotary) or integrated servo actuators (linear) specifically designed to pair with Moog drives for optimal performance.

Motion Controller (e.g., Moog IC/NC series): The higher-level controller that generates the motion profiles and position/velocity commands sent to theD136-001-007 drives over the network.

Feedback Devices: High-resolution resolvers or encoders (likeMoog P/N 70-xxx) attached to the motor and load, providing the essential position/speed data to the drive’s control loop.

Power Supply Module: A regulated DC power supply or transformer-rectifier unit that provides the clean DC bus voltage required by theD136-001-007 amplifier.

Tuning & Configuration Software (e.g., Moog MACC, Workbench): The PC-based software used to commission, parameterize, tune, and diagnose theD136-001-007 drive and its connected motor.

Fieldbus Master Module/Coupler: The network hardware (e.g., EtherCAT master) that integrates theD136-001-007 drives into the overall machine control system.

Installation, Maintenance, and Full-Cycle Support

Installation and commissioning of theMOOG D136-001-007 is a systematic process. It begins with secure mechanical mounting in a well-ventilated cabinet and proper grounding. Power, motor, and feedback cabling must be installed using shielded cables with correct grounding practices to minimize electrical noise. The commissioning phase, conducted via Moog’s configuration software, is critical. It involves auto-identifying the connected motor, configuring feedback and command sources, and executing a careful tuning procedure. This often includes an inertia identification routine and applying advanced filters to stabilize the mechanical system. Due to the high energies involved, initial power-up and testing should follow a strict safety protocol.

Routine maintenance is primarily preventative: ensuring cooling air paths are unobstructed, checking for loose electrical connections, and monitoring the drive’s internal temperature and error logs via the software. The most common “maintenance” activity is adapting the drive’s tuning to changes in the mechanical system (e.g., a different tooling payload). The drive’s advanced diagnostics are the first tool for troubleshooting, indicating faults like over-current, feedback error, or communication loss. More complex issues may require waveform capture of command and feedback signals using the software’s diagnostic tools.

Our support for theMOOG D136-001-007 addresses the needs of maintaining high-availability motion systems. We provide new or factory-certified refurbished units. We emphasize the importance of software and firmware version compatibility with your existing system. Our technical support can assist with configuration file recovery, basic troubleshooting guidance, and sourcing correct mating connectors and cables. For complex system issues, we can facilitate access to field service engineers specializing in Moog motion control. Our commitment is to provide not just a component, but the support necessary to minimize downtime and ensure your precision motion system performs as designed.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: