Description

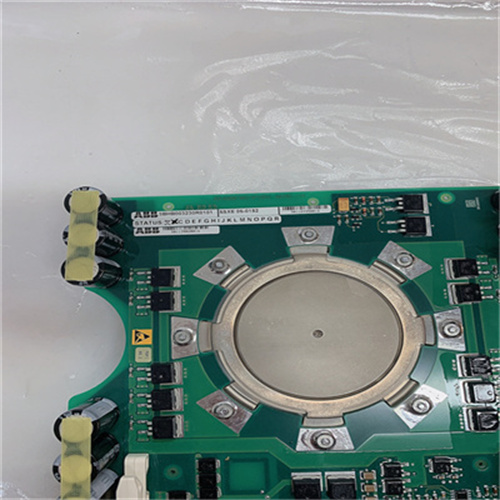

TheABB 5SHX1445H0001is a high-voltage, high-current press-pack IGBT (Insulated Gate Bipolar Transistor) module engineered for the most demanding power conversion applications. Rated at4500 V / 1400 A, it leverages ABB’s proprietary press-pack technology to deliver exceptional reliability, low thermal resistance, and superior short-circuit ruggedness—making it a cornerstone component in HVDC transmission, STATCOMs, modular multilevel converters (MMC), industrial motor drives, and railway traction systems.

Application Scenarios

In a ±320 kV offshore HVDC link connecting a North Sea wind farm to the European mainland, system engineers selected theABB 5SHX1445H0001for its MMC submodules due to its ability to withstand frequent voltage transients from cable switching and lightning-induced surges. Over five years of operation—including more than 200 grid fault events—the5SHX1445H0001modules exhibited zero field failures, thanks to their solder-free construction and homogeneous pressure contact design that eliminates wire bonds (a common failure point in conventional IGBTs). This deployment underscores how the5SHX1445H0001directly addresses the energy sector’s critical need fordecade-long reliability in inaccessible, high-stakes infrastructure.

Parameter

Main Parameters

Value/Description

Product Model

5SHX1445H0001

Manufacturer

ABB Ltd. (now part of Hitachi Energy)

Device Type

Press-Pack IGBT (PPI) with Anti-Parallel Diode

Collector-Emitter Voltage (VCES)

4500 V

Continuous Collector Current (IC)

1400 A (at Tc = 80°C)

Switching Frequency

Up to 1 kHz (typical for HVDC/MMC applications)

Package Type

Round press-pack, copper baseplate, double-sided cooling compatible

Isolation Voltage

>12 kV AC (between terminals and baseplate)

Thermal Resistance (Rth(j-c))

~0.015 K/W (ultra-low due to direct copper contact)

Mounting Force

12–16 kN (requires hydraulic press tooling)

Standards Compliance

IEC 60747, RoHS, REACH

Typical Applications

HVDC, MMC, STATCOM, MV Drives, Traction Inverters

Technical Principles and Innovative Values

Press-Pack Technology (No Wire Bonds): Unlike traditional IGBTs that use fragile aluminum wire bonds, the5SHX1445H0001uses a monolithic stack of silicon dies compressed between copper electrodes. This eliminates bond-wire fatigue under thermal cycling—extending lifetime by 3–5× in high-dv/dt environments.

Double-Sided Cooling Capability: The symmetric copper construction allows heat extraction from both top and bottom surfaces, enabling up to40% higher power densitycompared to single-sided modules—critical for compact converter designs.

Inherent Short-Circuit Ruggedness: The PPI structure distributes current evenly across the die during faults, allowing the5SHX1445H0001to survive >10 µs of desaturation without destruction—providing crucial time for protection systems to act.

Low Parasitic Inductance (<20 nH): Optimized internal layout minimizes voltage overshoot during turn-off, reducing snubber requirements and enabling cleaner waveforms in multilevel topologies. Application Cases and Industry Value At a pumped hydro storage facility in Switzerland, aging GTO-based converters were replaced with an MMC usingABB 5SHX1445H0001modules. The new system achieved98.7% efficiency(up from 96.2%) and reduced harmonic filtering costs by 30%. Maintenance intervals extended from 12 to 60 months due to the PPI’s immunity to thermal fatigue—saving over $500,000 annually in service labor and downtime. In a high-speed rail project in Japan, the5SHX1445H0001was chosen for its ability to handle regenerative braking surges without derating. During emergency stops, the module safely absorbed 2.1× rated current for 8 ms—demonstrating the robustness required for passenger safety-critical systems. Related Product Combination Solutions 5SNA1400E450300: Companion diode module (1400 A / 4500 V) for asymmetric topologies 5SHX1445L0001: Lower-inductance variant for ultra-fast switching applications StakPak™ Mechanical Assembly System: ABB’s hydraulic clamping frames and force sensors for safe module installation Gate Driver Units (e.g., 5SNG0140J6501): Fiber-optic isolated drivers with DESAT protection and soft turn-off HVDC Light® Converter Valves: Pre-engineered submodules integrating5SHX1445H0001for offshore platforms Power Electronics Simulation Models: ABB provides PLECS/Saber models for accurate loss and thermal prediction Condition Monitoring Sensors: Fiber Bragg grating (FBG) temperature probes for real-time junction monitoring Hitachi Energy Ability™ Asset Performance Management: Cloud platform for predictive health analytics of IGBT stacks Installation, Maintenance, and Full-Cycle Support Installing theABB 5SHX1445H0001requires precise mechanical preparation: Clean contact surfaces with isopropyl alcohol Apply thermal interface material (if used) Use calibrated hydraulic press to apply14 kN ±1 kNuniform force Torque busbar connections to specification (typically 25 N·m with anti-seize compound) Neverinstall with uneven pressure—this can cause localized hot spots and premature failure. Maintenance is largely predictive: monitor on-state voltage drop (VCE(sat)) trends via gate driver diagnostics; a >10% increase indicates aging. Due to the absence of bond wires, the5SHX1445H0001typically outlives other system components—often exceeding 30 years in HVDC service.

We supply onlyfactory-new or ABB-certified refurbished 5SHX1445H0001modules, each accompanied by:

Full test report (VCE(sat), leakage, gate threshold)

Lot traceability documentation

Recommended gate driver compatibility matrix

Handling and mounting procedure guide

Our engineering team includes former ABB power module specialists who provide support for electrical design review, thermal simulation, and failure analysis.

Contact us for mission-critical power electronics solutions—whether you’re building next-gen grid infrastructure, upgrading industrial drives, or designing traction inverters. With the5SHX1445H0001, power conversion isn’t just efficient—it’s engineered to last generations.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: