Description

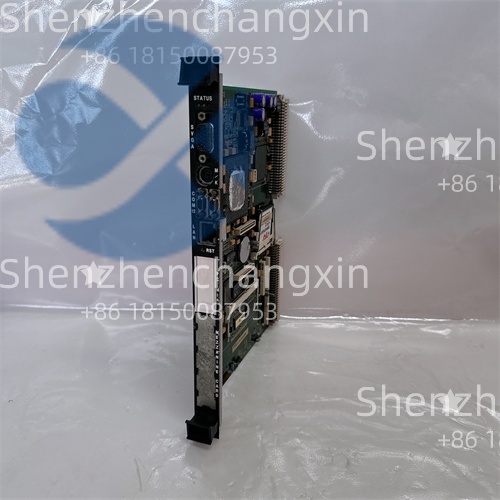

The GE IS215UCVEM09B is a VME Communication (VCM) I/O Pack module used within the GE Mark VIe or EX2100e turbine and excitation control systems. It functions as a critical communication and I/O interface node, providing a robust link between the central turbine controller and various field devices, and hosting application-specific control logic. This module is a key component in the distributed architecture of GE’s Speedtronic control platforms, enabling precise, reliable management and protection of industrial gas and steam turbines.

Application Scenarios

Imagine a large combined-cycle power plant where the gas turbine’s startup sequence, flame detection, and critical protection logic must execute with millisecond precision. A failure in the control hardware managing these functions could lead to a failed start, a costly turbine trip, or worse, a safety incident. The GE IS215UCVEM09B is deployed as a specialized I/O Pack within the Mark VIe rack dedicated to burner management and startup sequencing. It directly interfaces with flame scanners, ignition transformers, and fuel valve positioners. Its integrated processor runs the complex permissive and interlock logic locally, communicating status and alarms back to the main controller. In this role, the IS215UCVEM09B provides deterministic, localized control that offloads the main CPU, reduces network traffic, and enhances overall system reliability. For a maintenance team, a failure of this module means the turbine cannot be safely started until it is replaced, highlighting its critical role in plant availability and safety.

Parameter

Main Parameters

Value/Description

Product Model

IS215UCVEM09B

Manufacturer

General Electric (GE)

Product Category

VME Communication I/O Pack (VCM) for Mark VIe/EX2100e

Compatible System

GE Mark VIe Turbine Control System, EX2100e Excitation Control System

Primary Function

Application-specific I/O processing, sequencing, and communication interface.

Processor

Integrated microprocessor (PowerPC or similar architecture) for local control logic.

Memory

Onboard Flash and RAM for storing firmware and application code.

Communication

VMEbus Backplane (to system controller), Ethernet (for peer-to-peer, I/O network, or tool access).

I/O Handling

Interfaces with discrete and analog I/O through connected Terminal Boards (e.g., IS200/IS215 series).

Form Factor

Standard 6U VME form factor card for installation in a Mark VIe rack.

Key Feature

Executes fast, deterministic control loops and logic independent of the main controller (TCRK).

Technical Principles and Innovative Values

The GE IS215UCVEM09B embodies the core Mark VIe innovation of distributed, intelligent I/O, moving critical control functions closer to the point of action.

Innovation Point 1: Distributed Intelligence for Enhanced Speed and Reliability. Unlike a simple I/O scanner, the IS215UCVEM09B is an intelligent controller. It offloads time-critical, application-specific logic (like turbine startup sequences or trip functions) from the main turbine control rack (TCRK). This distribution allows for faster, deterministic execution of critical loops, reduces the computational load and communication traffic on the main controller, and localizes faults—a failure in one I/O Pack does not necessarily cripple the entire control system, thereby increasing overall availability.

Innovation Point 2: Standardized VME Architecture with Application Specialization. The module leverages the rugged, high-speed VMEbus standard for intra-chassis communication, ensuring reliable data exchange in electrically noisy environments. Its innovation lies in its specialized firmware. Each IS215UCVEM09B is programmed for a specific control application (e.g., turbine sequencing, protection, excitation control). This allows GE to use a common, reliable hardware platform across different functions, reducing spares inventory and simplifying maintenance training, while delivering optimized performance for each task.

Innovation Point 3: Dual Network Integration for Robust Communications. The module integrates seamlessly into the Mark VIe’s layered network architecture. It communicates with the system controller over the high-speed VME backplane for time-critical data. Simultaneously, its Ethernet port connects to the plant’s I/O or control network, allowing for data exchange with HMIs, historians, and other controllers, and providing a direct path for engineering tools (ToolboxST) for configuration and diagnostics. This dual-path communication enhances system integration and diagnostic accessibility.

Innovation Point 4: Advanced Diagnostics and Predictability. The IS215UCVEM09B features extensive onboard diagnostics that monitor its health, communication status, and the integrity of its assigned I/O points. This diagnostic data is fed to the plant’s asset management system. By analyzing trends—such as communication error rates or processor load—maintenance teams can shift from reactive to predictive strategies, identifying potential module or field device issues before they cause a process disturbance or trip, thereby improving overall plant reliability.

Application Cases and Industry Value

Case Study: Excitation Control Retrofit for a Hydroelectric Generator

A hydroelectric plant needed to upgrade the static exciter on a 100 MW generator to meet modern grid code requirements for voltage support and stability. The new GE EX2100e digital excitation system was installed. Within its cabinet, an IS215UCVEM09B I/O Pack served as the Voltage Regulator Controller (VRC). It ran the high-speed Automatic Voltage Regulator (AVR) and Power System Stabilizer (PSS) algorithms, processing signals from potential and current transformers to control the generator’s field current with precision. Post-retrofit, the generator demonstrated superior dynamic response during grid disturbances, maintaining voltage stability where the old system might have caused an oscillation. The plant engineer noted, “The IS215UCVEM09B-based controller gave us the computational speed and reliability needed for advanced control modes. Its deterministic performance was key to passing the stringent grid compliance tests.”

Case Study: Enhanced Turbine Protection in a Cogeneration Plant

A cogeneration plant using a GE Frame 6B gas turbine experienced a nuisance trip traced to a slow response in the overspeed protection logic, which was running on the main controller. During a control system upgrade to Mark VIe, a dedicated IS215UCVEM09B was configured as a Triple Modular Redundant (TMR) overspeed protection module. It was directly wired to three independent magnetic pickups and housed the 2-out-of-3 voting logic. This dedicated, hardware-based protection system provided a response an order of magnitude faster than the previous software-based solution, eliminating the nuisance trips. The plant manager reported, “By dedicating the IS215UCVEM09B to overspeed protection, we created a ‘safety instrumented system’ within the control architecture. Its performance is now predictable and failsafe, directly improving our unit’s reliability.”

Related Product Combination Solutions

The GE IS215UCVEM09B operates within a tightly integrated Mark VIe ecosystem. Key related components include:

IS200/IS215 Series Terminal Boards (e.g., IS200 EPAI, IS215): These boards provide the physical screw terminals for field wiring (analog inputs, digital I/O, thermocouples) and connect directly to the IS215UCVEM09B I/O Pack.

TCRK (Turbine Control Rack) with Controller (e.g., IS200 TBCIH): The main system controller rack. The IS215UCVEM09B resides in an I/O rack and communicates with the TCRK over the VME backplane or network.

PDM (Power Distribution Module): Provides clean, conditioned power to the IS215UCVEM09B and other modules in the rack. Critical for stable operation.

EX2100e Control Cubicle: The enclosure housing the excitation control system, where the IS215UCVEM09B would be installed as the regulator or sequencing controller.

ToolboxST Software: The essential engineering workstation software from GE used to configure the application logic, set parameters, and perform diagnostics on the IS215UCVEM09B.

CMM (Communications Module) or HMRI (Human Machine Interface): Provides the network gateway and operator interface, respectively, displaying data and alarms from the IS215UCVEM09B.

Legacy Equivalents: In some upgrade contexts, the IS215UCVEM09B may be a functional replacement for older Mark V or Mark IV cards (like DS200, IC200 series), but this requires careful engineering and migration.

Installation, Maintenance, and Full-Cycle Support

Installation and Commissioning: Installing an IS215UCVEM09B is a precise task. The module must be correctly aligned and firmly seated in its designated VME slot within the Mark VIe or EX2100e rack, then secured. The most critical steps occur in software using ToolboxST. The engineer must load the correct application firmware (e.g., for sequencing or excitation control) onto the module, configure its network settings (IP address, etc.), and map its I/O points to the correct process variables. A full functional test, verifying all inputs and outputs with the field devices, is mandatory before putting the system into service. Due to its critical role, installation is often performed during planned outages.

Maintenance and Troubleshooting: Primary maintenance is predictive and condition-based. The module’s health is monitored via ToolboxST and the plant’s asset management system. LED status indicators on the board provide immediate visual health checks. Common issues include communication faults (often related to network or backplane connections) and I/O channel faults (often related to field wiring or the terminal board). Troubleshooting involves using ToolboxST diagnostics to pinpoint the fault, checking connections, and potentially performing a module swap to isolate the issue. Firmware updates may be applied periodically.

Support and Service Commitment: We provide comprehensive lifecycle support for the GE IS215UCVEM09B. This begins with verifying the exact firmware revision and hardware version required for your specific application. We supply new, factory-sealed, or certified refurbished modules that have undergone rigorous testing. Our technical support can assist with configuration file management, compatibility questions, and basic diagnostics. For complex system integration or troubleshooting, we can facilitate access to field service engineers specialized in GE Speedtronic systems. Our goal is to ensure you have a reliable source for this critical component and the knowledge to keep your turbine control system operating at peak performance.

Ensure the reliability and performance of your turbine control system with the right components. Contact us for the genuine GE IS215UCVEM09B I/O Pack and expert technical support for your Mark VIe or EX2100e application.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: