ABB 5SHY4045L0006 IGBT Module|High-Power StakPak for Medium Voltage Drives

5SHY4045L0006 Power Semiconductor|ABB StakPak IGBT 4500V 1200A

ABB 5SHY4045L0006 IGBT|Core Switching Component for ACS 2000 Drives

5SHY4045L0006 StakPak Module|Critical Power Stage for Industrial Converters

ABB 5SHY4045L0006 Power Transistor|Rugged IGBT for High-Current Applications

5SHY4045L0006 IGBT Power Stack|Essential Spare for ABB Medium Voltage VSDs

ABB 5SHY4045L0006 Switching Device|For Mining,Marine,and Energy Applications

5SHY4045L0006 Power Module|High-Reliability IGBT in StakPak Technology

ABB 5SHY4045L0006 Insulated Gate Bipolar Transistor|Engineered for Demanding PWM

5SHY4045L0006 Drive Power Component|Key to Reliable Motor Control and Efficiency

Description

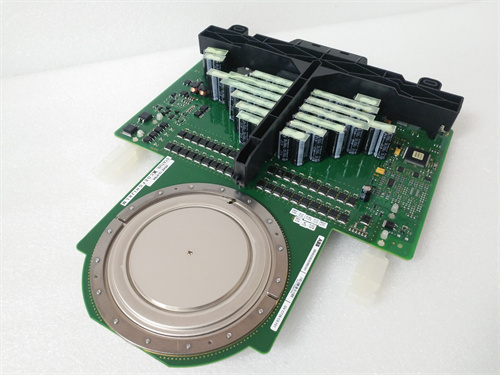

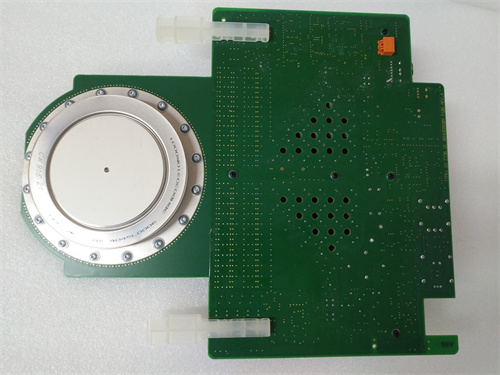

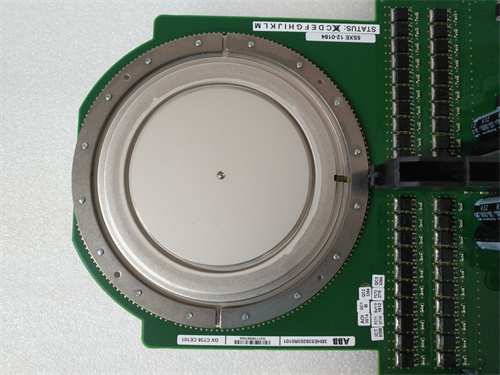

The ABB 5SHY4045L0006is a high-power IGBT(Insulated Gate Bipolar Transistor)module,a fundamental component in ABB’s StakPak power electronics family.It functions as the primary switching element in medium voltage variable speed drives(VSDs)and other power conversion equipment,efficiently controlling the flow of high electrical power to motors and loads.This robust module is engineered to deliver reliable performance in the most demanding industrial environments,serving as the workhorse for precise motor control and energy conversion.

Application Scenarios

In a large copper mine,the reliability of the ore grinding mill is paramount to production.The mill is driven by a 6 MW synchronous motor controlled by an ABB ACS 2000 medium voltage variable speed drive.At the heart of each inverter section within this drive sits the ABB 5SHY4045L0006IGBT module.During operation,these modules switch at high frequencies,synthesizing the precise AC waveform needed to control the motor’s speed and torque.When the mill experiences a sudden load spike from a particularly dense section of ore,the 5SHY4045L0006modules,in conjunction with the drive’s control system,manage the inrush current,preventing a nuisance trip and allowing the mill to power through.The mine’s maintenance supervisor highlights that the rugged design and predictable wear-out characteristics of the StakPak IGBTs allow for proactive replacement during planned outages,virtually eliminating unplanned drive failures that could cost over$100,000 per hour in lost production.

Parameter

The ABB 5SHY4045L0006is a high-power discrete IGBT.Its key parameters define its electrical capabilities and physical form.

Main Parameters

Value/Description

Product Model

5SHY4045L0006

Manufacturer

ABB

Product Category

High-Power IGBT Module(StakPak Platform)

Module Technology

IGBT(Insulated Gate Bipolar Transistor)/Diode Pair

Voltage Rating(Vces)

4500 V

Current Rating(Ic)

1200 A

Package Type

ABB StakPak(Press-pack)

Mounting

Spring-loaded pressure contact system

Isolation Voltage

High isolation to baseplate

Weight

Approximately 2.5 kg(module-specific)

Typical Applications

Medium Voltage Drives(e.g.,ACS 2000),Industrial Power Conversion

Technical Principles and Innovative Values

The ABB 5SHY4045L0006is not a simple transistor;it represents a sophisticated approach to managing megawatts of power with precision and reliability.

Innovation Point 1:Press-Pack(StakPak)Design for Superior Ruggedness and Cooling

Unlike conventional module packages that use solder and bond wires,the StakPak employs a press-pack design.The silicon chips are pressed between electrical contacts and a heatsink using a calibrated spring system.This eliminates solder fatigue—a common failure mechanism in power cycling applications—and provides a direct,low-thermal-resistance path for heat dissipation.This design makes the 5SHY4045L0006exceptionally robust against thermal cycling,a critical factor in drives that frequently start and stop large motors or handle dynamic loads.

Innovation Point 2:Asymmetric Ruggedness for Short-Circuit Withstand

The 5SHY4045L0006IGBT is designed with inherent ruggedness.It can typically withstand a short-circuit condition across its outputs for a specified time(e.g.,10 microseconds)without destruction.This characteristic gives the drive’s control system a critical window to detect the fault and safely shut down the switching pulses.This built-in robustness is essential for surviving real-world fault conditions in industrial power networks,such as motor insulation failures,providing a vital layer of protection for the entire drive system.

Innovation Point 3:Optimized for Series and Parallel Operation

The electrical characteristics of the 5SHY4045L0006are tightly controlled,making it ideal for connecting multiple devices in series to achieve higher voltage ratings(e.g.,in a multi-level inverter topology)or in parallel for higher current output.The StakPak mechanical design ensures consistent,reliable pressure contact across all devices in a stack,which is crucial for current sharing in parallel configurations and voltage sharing in series configurations.This scalability is fundamental to building drives for a wide range of power ratings using a standardized power component.

Innovation Point 4:Integration with ABB’s Gate Unit Ecosystem

The 5SHY4045L0006is designed to work seamlessly with ABB’s dedicated gate drive units(GDUs),such as the SPGU-2406A.This synergy is critical.The GDU provides the perfectly shaped,high-current gate drive signals needed to switch the IGBT quickly and efficiently,minimizing switching losses.It also provides advanced protection features like desaturation detection,active clamping,and soft shutdown.This co-engineering between the IGBT and its driver maximizes performance and reliability.

Application Cases and Industry Value

Case Study:Reliability Upgrade for a Petrochemical Plant’s Critical Compressor Drive

A major ethylene plant relied on a 12 MW fixed-speed steam turbine driving a propylene compressor.To achieve significant energy savings,the plant retrofitted the system with an ABB ACS 2000 variable speed drive,allowing the steam turbine to run at optimal speed while the drive controlled the compressor.The inverter cabinets of this drive utilize multiple ABB 5SHY4045L0006modules per phase.During commissioning,the drive was subjected to rigorous factory testing,including a full-power back-to-back load test.The 5SHY4045L0006modules performed flawlessly,handling the high dv/dtand di/dtstresses inherent in PWM switching.In the five years since commissioning,the drive has achieved over 99.8%availability,saving an estimated 15%of the compressor’s energy consumption—amounting to several million dollars.The plant’s electrical engineer specifically praised the predictive maintenance capability;periodic monitoring of the gate driver boards’monitoring points allows them to track the health of the IGBTs and plan replacements during scheduled turnarounds,avoiding catastrophic failures.

Related Product Combination Solutions

The ABB 5SHY4045L0006is a core component within a complete medium voltage drive power stack.Its operation depends on and is supported by several other critical components:

Gate Drive Unit(GDU)-e.g.,ABB SPGU-2406A:This is the essential companion to the 5SHY4045L0006.It provides the optical isolation,power amplification,and protection logic needed to safely and efficiently switch the IGBT.

DC-Link Capacitors-e.g.,ABB or Specialized Manufacturer Banks:These large capacitor banks smooth the rectified DC bus voltage and provide the instantaneous current needed by the IGBTs during switching.Their reliability is crucial for overall system health.

Clamp Diode/Chopper Module-e.g.,ABB 5SNA:In some drive topologies,a separate clamp or chopper module is used to manage overvoltage transients,protecting the 5SHY4045L0006and other components.

Water-Cooled Heatsink:The StakPak module mounts directly onto a liquid-cooled heatsink.Efficient cooling,with precisely controlled deionized water flow,is non-negotiable for maintaining the IGBT’s junction temperature within safe limits.

Voltage Sharing Resistors/Capacitors:When 5SHY4045L0006modules are stacked in series for higher voltage levels,auxiliary resistor and capacitor networks are used to ensure static and dynamic voltage sharing is equal across each device.

Current Sensors-e.g.,LEM or ABB Sensors:High-bandwidth,isolated current sensors(like Hall-effect or Rogowski coils)measure the output phase currents.This feedback is critical for the drive’s control and protection algorithms that ultimately command the 5SHY4045L0006.

Fiber Optic Cables:The gate drive signals are transmitted via fiber optic cables from the control board to the GDU.This provides perfect electrical isolation and immunity to the extreme electromagnetic noise present in the power stack.

Installation,Maintenance,and Full-Cycle Support

Installation of the ABB 5SHY4045L0006is a precise procedure that must be performed by qualified personnel.The module is placed into its designated position in the power stack assembly.The most critical step is applying the correct contact pressure via the spring mechanism;this is typically done with a calibrated torque wrench on the clamping bolts.Insufficient pressure leads to high resistance and overheating,while excessive pressure can crack the silicon die.Proper application of thermal interface material(TIM)or the use of pre-applied thermal pads is essential for optimal heat transfer to the heatsink.Electrical connections to the main DC bus and AC output are then made,ensuring all busbars are clean,flat,and torqued to specification.

Routine maintenance focuses on the supporting systems.The cooling circuit’s flow,pressure,temperature,and conductivity must be monitored and maintained regularly.Visual infrared thermography during operation can identify hot spots indicating loose connections or failing thermal interfaces.The gate driver boards should be inspected for capacitors showing signs of wear.The 5SHY4045L0006module itself has no serviceable parts.Predictive maintenance involves trending parameters like the IGBT’s saturation voltage(Vce(sat))or gate charge requirements,which can be inferred from GDU monitoring points,to plan replacement before failure.Replacing a module requires a full power-down,discharge,and lock-out/tag-out procedure.After replacement,the new module’s pressure and electrical connections must be verified meticulously.

We provide comprehensive support for the ABB 5SHY4045L0006and the complete StakPak ecosystem.We supply genuine and certified refurbished modules,all subjected to full electrical characterization testing.Our services include thermal interface refurbishment kits and precision torque tools for installation.Our technical team can assist with failure analysis,root cause investigation,and provide guidance on proper storage,handling,and installation procedures to maximize module life.We are committed to being your partner in maintaining the highest levels of uptime and performance for your critical medium voltage drives.

选择深圳长欣,享受无忧的售后服务和高品质产品。

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: