Description

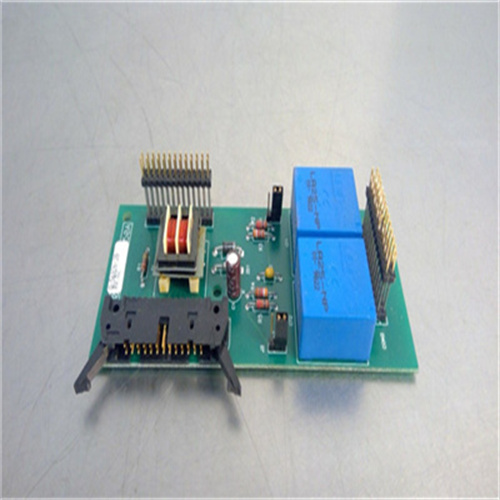

The RELIANCE 0-60067-Ais a servo drive control module manufactured by Reliance Electric,designed as a core component within the AutoMax Distributed Control System(DCS)or other related Reliance drive platforms.This module functions as the intelligent controller for a servo axis,responsible for executing motion profiles,regulating torque,speed,and position,and ensuring precise synchronization in complex industrial machinery.It represents a critical link in automation systems requiring high-accuracy motion control.

Application Scenarios

In a high-speed packaging line for consumer goods,the precise placement of items onto a moving conveyor is critical.A rotary cutting and sealing station uses a servo-driven mechanism controlled by a RELIANCE 0-60067-Amodule within an AutoMax system.The 0-60067-Areceives a position command from the master controller and,using high-resolution feedback from an encoder on the servo motor,dynamically adjusts the motor’s current to achieve perfect synchronization with the conveyor’s speed.During a production run,a sudden change in product size was required.The flexible programming of the AutoMax system allowed engineers to quickly upload a new motion profile to the 0-60067-A.The module seamlessly adapted,changing the cut length on-the-fly without stopping the line,demonstrating its critical role in maintaining throughput and enabling flexible manufacturing.The plant manager credited the reliability and precision of the drive system,centered on the 0-60067-A,for achieving a 99.8%operational uptime for the packaging section.

Parameter

The RELIANCE 0-60067-Ais a key component within a larger drive system.Its parameters are defined by its role as a servo controller.

Main Parameters

Value/Description

Product Model

0-60067-A

Manufacturer

Reliance Electric

Product Category

Servo Drive Control Module/Motion Controller

Compatible System

Reliance AutoMax Distributed Control System

Control Function

Servo Axis Control(Speed,Torque,Position)

Feedback Interface

High-resolution encoder feedback(Resolver/Encoder input)

Command Interface

AutoMax backplane communication for setpoints and commands

Output to Amplifier

Analog torque/speed command signal(±10V typical)

Power Requirements

+5VDC,±15VDC from the AutoMax rack or internal power supply

Status Indicators

LED indicators for power,fault,and communication status

Protection Features

Overcurrent,overtemperature,and feedback loss protection

Operating Temperature

0°C to 60°C(standard industrial range)

Technical Principles and Innovative Values

The RELIANCE 0-60067-Aembodies the integration of precise motion control within a distributed architecture,a significant advancement over standalone drives at the time of its design.

Innovation Point 1:Tight Integration with Distributed Control Architecture

Unlike a standalone servo drive,the 0-60067-Ais a card that plugs directly into the AutoMax DCS rack.This allows motion control logic to reside on the same high-speed backplane as the PLC logic,I/O scanning,and operator interface communication.This integration enables extremely low-latency data exchange between the motion controller and other system components,facilitating complex coordinated multi-axis movements and seamless integration of motion with process control logic,all programmed within a single software environment.

Innovation Point 2:Advanced Control Algorithms for Precision

The module employs sophisticated control algorithms,likely including PID with feedforward and advanced filtering.It processes high-frequency encoder feedback(potentially up to millions of counts per revolution)to close the position loop with minimal error.This allows for precise trajectory following,essential in applications like contouring,flying shear cuts,and registration control.The ability to handle high-inertia loads and compensate for mechanical backlash through software was a key differentiator,improving the accuracy of existing machinery.

Innovation Point 3:Programmable Flexibility within a Robust Platform

The 0-60067-Awas not a fixed-function device.Its behavior was defined by configuration and logic loaded from the AutoMax programming software.This allowed engineers to customize motion profiles,implement complex sequences,and create sophisticated fault recovery routines.This flexibility meant one hardware platform could be used for a wide variety of applications—from simple indexing to complex electronic gearing—reducing spare parts inventory and simplifying maintenance training.

Innovation Point 4:Comprehensive Diagnostics and Protectives

The module was designed for reliable operation in an industrial environment.It continuously monitors its own health and the status of the connected servo motor and amplifier.Key diagnostics included tracking of following error,excessive current demand,and feedback signal integrity.Upon detecting a fault,it could safely shut down the axis and report a detailed fault code back to the main controller,drastically reducing mean-time-to-repair(MTTR)for drive-related issues.

Application Cases and Industry Value

Case Study:Modernization of a Steel Slitting Line

A steel service center operated an aging slitting line where the synchronization between the uncoiler,slitter head,and recoiler was mechanically geared,limiting speed,accuracy,and product changeover flexibility.The line was modernized with a Reliance AutoMax DCS,using RELIANCE 0-60067-Amodules to control servo drives on each axis.The electronic line-shaft synchronization provided by the AutoMax system and the 0-60067-Amodules replaced the physical gearbox.The results were transformative:setup times for different coil widths and thicknesses were reduced from 45 minutes to under 5 minutes via recipe selection.The precision of the electronic gearing eliminated”scalloping”on the edge of the slit strips,improving material yield by 2%.Furthermore,the line speed could be increased by 25%without loss of quality.The project payback was achieved in under 18 months through reduced scrap and increased throughput,with the reliability of the 0-60067-Abased system contributing to a 40%drop in drive-related downtime.

Related Product Combination Solutions

The RELIANCE 0-60067-Afunctions as the controller within a complete motion control subsystem.A typical system includes:

AutoMax Processor/Controller(e.g.,Reliance 57C410):The main DCS/PLC processor that runs the overall machine logic and coordinates multiple 0-60067-Aservo axes.

AutoMax Rack and Power Supply(e.g.,Reliance 57C400):The physical chassis and power source that houses the processor,0-60067-Amodules,and other I/O cards.

Servo Amplifier/Power Stage(e.g.,Reliance GV3000 or similar):This unit accepts the low-voltage command signal from the 0-60067-Aand provides the high-current AC power to the servo motor.The 0-60067-Ais its”brain.”

Servo Motor(Reliance or other brand):The high-performance motor with a built-in feedback device(encoder/resolver)that provides precise mechanical motion.Models like the Reliance SP600or SM600series are common pairings.

Feedback Device(Encoder/Resolver):This critical component,often built into the motor,provides precise position and speed data back to the 0-60067-Ato close the control loop.

Programming Software(AutoMax Workshop):The proprietary software environment used to configure,program,and troubleshoot the entire AutoMax system,including the logic for the 0-60067-Amodules.

I/O Modules(Various 57C-series):Digital and analog I/O cards in the same AutoMax rack for interfacing with limit switches,sensors,and other machine peripherals,all communicating seamlessly with the motion control logic.

Installation,Maintenance,and Full-Cycle Support

Installation of the RELIANCE 0-60067-Arequires careful handling and proper system integration.The module must be inserted into a compatible slot in the AutoMax rack,ensuring the backplane connector is fully seated.Prior to power-up,it is crucial to verify that the rack’s power supply voltages are within specification.The connected servo amplifier must be correctly sized for the motor,and the feedback cable from the motor’s encoder to the module must be shielded and properly grounded to prevent electrical noise from causing erratic behavior.Configuration is performed entirely within the AutoMax Workshop software,where the servo axis is defined,tuned,and integrated into the overall control program.

Routine maintenance is primarily preventive and diagnostic.Keeping the control cabinet clean and ensuring adequate cooling is essential.Periodically,the system’s diagnostic logs should be reviewed for any recurring warnings.The tuning parameters of the 0-60067-A(e.g.,PID gains)should be verified,especially if mechanical components in the drive train are replaced.Common issues include fault codes related to feedback loss(check encoder wiring and connections)or overcurrent(check the motor and mechanical load for binding).The module itself is a solid-state device with no user-serviceable internal parts.If diagnostics point to a module failure,it is replaced.Having a pre-configured spare module on-site can minimize downtime,as the configuration is typically stored in the main processor’s memory or on a backup memory card.

We provide comprehensive support for legacy Reliance AutoMax systems and components like the 0-60067-A.We source and supply genuine,tested replacement modules.Our technical team understands the intricacies of these systems and can assist with troubleshooting,configuration recovery,and integration challenges.We also offer repair services for faulty control cards and can help identify modern upgrade paths for systems where long-term support for legacy components is a concern.Our goal is to ensure your critical motion control applications continue to run reliably and efficiently.

选择深圳长欣,享受无忧的售后服务和高品质产品。

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: