Description

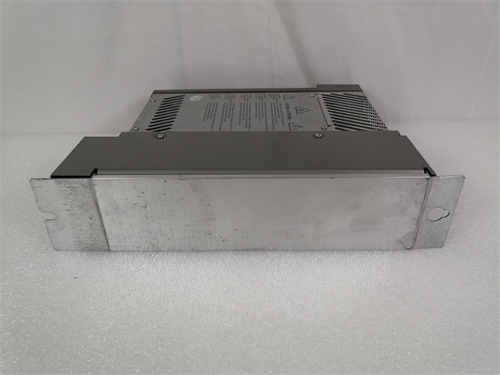

The ELAU MC-4/11/03/400is a digital servo drive module manufactured by ELAU(now part of Schneider Electric Motion USA)for its advanced automation systems.It is a member of the ELAU C400 line of intelligent,modular drive and control components.This module functions as a high-performance,digitally controlled amplifier designed to precisely drive brushless servo motors in demanding multi-axis motion applications,particularly prevalent in packaging,assembly,and material handling machinery.

Application Scenarios

Imagine a high-speed bottling line where a servo-driven rotary filler must synchronize perfectly with an incoming conveyor,index bottles with micron-level precision,execute the filling cycle,and then transfer them without spillage—all at rates of hundreds of bottles per minute.The ELAU MC-4/11/03/400is the component that makes this possible.It receives high-level motion commands(position,velocity,torque)from a central PacDrive or C400 controller via a high-speed SERCOS fiber-optic ring.The drive then translates these commands into the precise three-phase AC power needed to control the torque and position of the filler’s servo motor.Its integrated control loops and”smart”features handle the real-time complexities of motor commutation,current control,and following error management.This allows machine builders to create complex,tightly synchronized mechanical systems with reduced engineering time,as the drive handles low-level motor control,freeing the central PLC to manage higher-level logic and sequencing.

Parameter

Main Parameters

Value/Description

Product Model

MC-4/11/03/400

Manufacturer

ELAU/Schneider Electric Motion USA

Product Category

Digital Servo Drive/Amplifier Module

Output Current

11 A RMS(Continuous),33 A(Peak)

Output Power

Typically corresponds to a 3-7 kW servo motor range

Supply Voltage

3-Phase,400 VAC(Nominal,340-480 VAC range)

Control Technology

Digital PWM amplifier with space vector modulation

Communication

Integrated SERCOS interface(fiber optic)for connection to ELAU controllers(e.g.,PacDrive)

Motor Feedback

Supports digital(EnDat,HIPERFACE)and analog(sin/cos 1Vpp)encoders/resolvers

Programming

Configured and tuned via ELAU’s EPAS-4 software suite

Safety

Integrated Safe Torque Off(STO)functionality(on supported models)

Key Feature

Part of a modular system;can be combined with other MC-4 drives and control modules in a single rack.

Technical Principles and Innovative Values

The ELAU MC-4/11/03/400embodies a system-level approach to motion control,where intelligence is distributed between the central controller and the drive itself.

Innovation Point 1:Truly Distributed,Intelligent Motion Control:Unlike simple amplifiers,the MC-4/11/03/400contains a powerful digital signal processor(DSP).It executes critical,high-speed control loops(current,velocity)locally.This distributed intelligence reduces the computational load on the main controller and minimizes communication latency,enabling faster,more deterministic control of the connected motor.The central controller sends trajectory commands,and the drive handles the real-time execution.

Innovation Point 2:Seamless SERCOS Network Integration:The drive is designed for the SERCOS(Serial Real-time Communication System)automation bus,a high-performance,deterministic fiber-optic ring network.This allows multiple MC-4/11/03/400drives and other devices to be synchronized with sub-millisecond precision.The network is highly noise-immune and simplifies cabling,enabling the creation of complex multi-axis systems with perfectly coordinated motion,which is essential for applications like electronic line shafting in printing or converting machinery.

Innovation Point 3:Automatic Motor Identification and Adaptive Control:Through the EPAS-4 software,the drive can automatically identify the connected servo motor’s electrical parameters(resistance,inductance,back-EMF constant).It uses this data to auto-tune its current and velocity loops for optimal performance.Furthermore,its control algorithms can adapt to changing load conditions,maintaining high performance and stability—a key advantage in applications where the load inertia changes,such as in winding or unwinding stations.

Application Cases and Industry Value

Case Study:High-Speed Cartoning Machine Performance Upgrade

A manufacturer of pharmaceutical cartoning machines needed to increase throughput by 25%without sacrificing precision or reliability.The existing servo system was struggling with settling times and following errors at higher speeds.The integrator upgraded the machine’s motion system using an ELAU PacDrive controller and multiple ELAU MC-4/11/03/400drives for the main forming,loading,and sealing axes.

Process&Improvement:The new drives,with their faster digital processing and superior loop tuning capabilities,provided much stiffer control of the servo motors.The SERCOS network synchronization eliminated the mechanical play and timing errors associated with the old central cam controller.The automatic tuning feature in EPAS-4 quickly optimized each axis for its specific mechanical load.The result was a 30%increase in machine speed while actually improving positioning accuracy.The head of engineering noted,”The MC-4/11/03/400drives were the key.Their responsiveness allowed us to push the mechanical limits of the machine.The reduction in tuning time alone saved us weeks of commissioning.”

Related Product Combination Solutions

The ELAU MC-4/11/03/400is a core component within the modular C400 and PacDrive ecosystems.It is designed to work in concert with these specific products:

ELAU PacDrive L系列or C400 Controller(e.g.,MC-4/CPU/01):The central motion and logic controller.The MC-4/11/03/400drive receives its motion commands from this CPU module via the SERCOS ring.

ELAU MC-4 Power Supply Module(e.g.,MC-4/PS/400):Provides the regulated 400VDC bus voltage from the 3-phase AC mains to the MC-4/11/03/400and other drives in the rack.

ELAU Servo Motors(e.g.,PLE-3/60/3/2000):The brushless servo motors specifically designed and matched for optimal performance with the ELAU drive family.The MC-4/11/03/400is configured with the exact motor data for precise control.

ELAU EPAS-4 Engineering Software:The essential configuration,programming,and tuning suite for the entire system.It is used to set all drive parameters,configure the network,commission the motors,and develop the application logic.

Other MC-4 Drive Modules(e.g.,MC-4/07/03/400):Drives with different current ratings(e.g.,7A)for smaller axes within the same machine,all sharing the same rack,power supply,and network.

ELAU Digital I/O Modules(e.g.,MC-4/I/O):For connecting sensors,buttons,and actuators.These modules also reside in the same rack and are programmed from the same EPAS-4 environment,creating a unified control architecture.

SERCOS Fiber-Optic Cables and Interface Modules:The physical network components that create the deterministic ring connecting the controller,drives,and other intelligent devices.

Installation,Maintenance,and Full-Cycle Support

Installation of the ELAU MC-4/11/03/400involves mounting it securely in a dedicated C400 rack or cabinet,ensuring adequate clearance for cooling.Electrical installation requires a qualified professional to connect the 3-phase AC input(via a suitable contactor and filter),the motor power and feedback cables,and the SERCOS fiber-optic loop.Proper grounding and shielding are critical to prevent electrical noise.Configuration is performed entirely through the EPAS-4 software,where the drive is added to the hardware configuration,the motor type is selected or identified,and the control loops are tuned.

Routine maintenance primarily involves ensuring the cooling fans(if present)and heatsinks are clean and unobstructed.The EPAS-4 software provides extensive diagnostic tools,including oscilloscope functions to trace following error,current,and velocity,which are invaluable for troubleshooting.The most common”maintenance”action is a firmware update or parameter reload via the software.Module replacement is straightforward:after a backup is secured,the faulty module can be swapped,and its configuration downloaded from the project file.

We provide dedicated support for this specialized motion control component.We understand the critical role these drives play in complex machinery.Our technical team can assist with compatibility checks,provide configuration guidance,and help source the correct associated parts.We are committed to supporting the longevity of your ELAU-based automation systems with reliable products and expert knowledge.Contact us for a comprehensive solution to keep your high-performance motion applications running smoothly.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email:

-110x80.png)