Description:

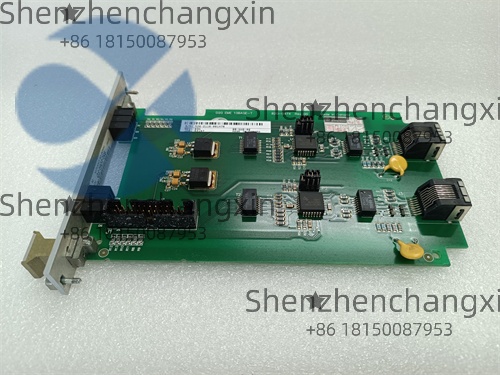

The GE D20 EMEis a critical controller module,specifically the Ethernet Main Ethernet(EME)board,within GE’s Speedtronic Mark VIe turbine control system.It serves as a core processing and communication unit,managing input/output operations,executing control logic,and facilitating high-speed data exchange for the safe and efficient operation of gas and steam turbines.

Application Scenarios:

In a combined-cycle power plant,the gas turbine’s operation must be meticulously controlled and monitored,with thousands of parameters like temperature,pressure,vibration,and valve position processed hundreds of times per second.The GE D20 EMEmodule is the computational heart of this operation.Installed in a triple-redundant(TMR)rack in the control room,it runs the complex protection and sequencing logic.It gathers data from sensors via I/O packs,calculates corrective actions to maintain setpoints,and issues commands to actuators.Its integrated high-speed Ethernet interfaces allow it to communicate seamlessly with the plant’s Distributed Control System(DCS)and other D20 EMEmodules for coordinated control.Its failure is not an option,as it directly governs the turbine’s startup,loading,and safe shutdown sequences,protecting hundreds of millions of dollars in capital equipment.

Parameter:

Main Parameters

Value/Description

Product Model

D20 EME

Manufacturer

General Electric(GE)

Product Category

Controller/Ethernet Main Ethernet Module for Mark VIe

Compatible System

GE Speedtronic Mark VIe Turbine Control System

Primary Function

I/O Control,Sequence Logic Execution,Network Communication

Processor

High-performance dedicated processor for real-time control

Memory

Onboard RAM and non-volatile memory for application storage

Control Network

Integrated triple Ethernet ports for peer-to-peer(TMR)and plant network communication

I/O Communication

High-speed link to<I/O Pack>modules(e.g.,VCMI,TCMI)

Redundancy

Designed for Triple Modular Redundant(TMR)configuration

Diagnostics

Comprehensive self-test and status reporting capabilities

Power Supply

Powered from the Mark VIe rack’s backplane

Technical Principles and Innovative Values:

Innovation Point 1:Triple Modular Redundant(TMR)Architecture for Maximum Availability.The D20 EMEis designed to operate as one channel in a three-channel TMR system.Three identical modules run in perfect synchronization,each executing the same logic.A hardware voting mechanism on critical outputs ensures that a single failure(in one D20 EME)is masked by the other two,preventing a spurious trip or erroneous control action.This architecture,central to the Mark VIe,provides an exceptional level of fault tolerance,making it suitable for the most critical turbine protection functions where unplanned downtime is catastrophic.

Innovation Point 2:Deterministic,High-Speed Control Execution.The module is engineered for hard real-time performance.It operates on a fixed,rapid scan cycle,guaranteeing that all input data is read,control algorithms are solved,and output commands are issued within a predictable,sub-millisecond timeframe.This deterministic behavior is non-negotiable for fast-acting control loops like fuel metering or overspeed protection,where timing delays can lead to instability or equipment damage.

Innovation Point 3:Integrated High-Performance Networking.The”E”in EME stands for Ethernet.The module features integrated,ruggedized industrial Ethernet ports.These are used for the high-speed,low-latency communication required for synchronization between the three TMR channels and for connecting to the plant’s supervisory network.This integration eliminates the need for separate network interface cards,simplifies cabling,and provides a standardized,high-bandwidth pathway for data exchange with HMIs,engineering stations,and historians.

Application Cases and Industry Value:

Case Study:Pipeline Compressor Station Control System Modernization.A natural gas pipeline company needed to upgrade the control system for several remote compressor stations driven by gas turbines.The legacy system was unreliable,leading to unscheduled outages that disrupted gas flow.

The company standardized on GE’s Mark VIe system.Each turbine was fitted with a new control cabinet containing a TMR set of D20 EMEcontrollers.These modules were programmed to handle the complex anti-surge control logic for the compressor,turbine sequencing,and station auxiliaries.The built-in Ethernet allowed for secure,remote monitoring and control from a central pipeline SCADA system.Post-installation,the stations achieved over 99.9%availability.The lead engineer noted that the D20 EME’s reliability and powerful diagnostics allowed for predictive maintenance,and the TMR design provided the confidence to let the stations run unattended.The project resulted in a 15%increase in pipeline throughput efficiency and a dramatic reduction in maintenance call-outs,delivering a full ROI in under two years.

Related Product Combination Solutions:

The D20 EMEis the central processor within a Mark VIe control node.Essential complementary components include:

VCMI(Variable Control Module I/O)Packs:The primary I/O interface modules(e.g.,IS200VCMIH2C)that connect to field devices and communicate with the D20 EME.

TCMI(Turbine Control Module I/O)Packs:Specialized I/O modules for critical turbine signals.

Mark VIe Rack&Backplane:The VME chassis that houses and interconnects all controller and I/O modules.

Power Supply Modules:Provide clean,redundant DC power to the rack(e.g.,IS200PSCAH1A).

Termination Boards:Interface panels that provide screw terminals for field wiring to the I/O packs.

HMI/Workstation:Computers running GE’s ToolboxSTsoftware for engineering and Cimplicityor other SCADA for operation,all communicating with the D20 EMEover Ethernet.

Network Switches:Managed industrial Ethernet switches to form the plant control network connecting the controllers.

Installation,Maintenance,and Full-Cycle Support:

Installation is a specialized task performed by qualified technicians.The module is carefully inserted into its designated slot in the Mark VIe rack and secured.Critical attention is paid to network cable connections for the TMR synchronization and plant data networks.Configuration and application download are performed using GE’s proprietary ToolboxST software.The system undergoes extensive loop checks and functional testing before commissioning.

Routine maintenance involves monitoring module health(via HMI diagnostics),ensuring firmware is up to date,and performing periodic controller switchover tests to verify redundancy during planned outages.A significant advantage of the TMR design is the ability to perform”hot”maintenance.A single D20 EMEmodule in a trio can be powered down,removed,and replaced without causing a turbine trip,as the remaining two channels maintain control.We provide comprehensive lifecycle support for the D20 EME.Our units are sourced from certified channels and undergo rigorous testing,including firmware verification and communication diagnostics.We offer technical support for troubleshooting,configuration migration,and legacy system upgrades,ensuring the continued reliability and performance of your critical turbine control assets.

UFC921A101 3BHB024855R0101 UFC911B106 3BHE037864R0106 UDC920BE01 3BHE034863R0001 XVC770BE101 3BHE021083R0101 KUC755AE105 3BHB005243R0105 LXN1604-6 3BHL000986P7000 LWN2660-6E 3BHL000986P7002 UFC789AE 38HE014022P102 3BHL000734P0003 SLOV4.6/5.3 HIES308461R0012 HIES208441R.. ID8A92485001/022 3BHB009410R000 SG000247 3BHL000986P1006 XVC724BE101 3BHE009017R0102 DKTFM418B 3BHB015651P0001 PU180/63E 3BHB00916230001 HIES308461R0012 FPX86-9345–B 3BHL000986P0006 3BHL000734P0003 SLOV4.6/5.3 UFC921A101 3BHE024855R0101 PPC907BE101 3BHE024577R0101 XVC724BE101 3BHE009017R0102 IEC60129,62271-102 MI-CONP KUC755AE105 3BHB005243R0105 HIES308461R0012 MG160MD2-42FF300-F1 PTC 160℃ TP211 MG160MD2-42FF300-F1 ABB S-073N ALU 3BHB009884R5211 ABB S-093H 3BHB030478R0309 ABB S-123H 3BHB030479R0512 ABB UFC912A101 3BHE039426R0101 ABB 5SHY4045L0001 3BHB018162R0001 ABB S-113N 3BHB018008R0001 W4 KUC755AE105 3BHB005243R0105 HIEE401807R0001 3BHB046719R0008 STRAUB FLEX1L TB820V2 S-053M 3BHB012897R003 *12 3BHB014556R0001 3BHB010823R0002 CDP312R XVC768AE102 UFC789AE101 S-073N KU C755AE105 XVC770BE101 UFC760BE42 PPC907BE UFC760BE43 XVC769AE101 LDMTR-01 UAC389AE02 LTC391AE01 PPC905AE101 UAC383AE01 LDLPTR-01

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: