Description

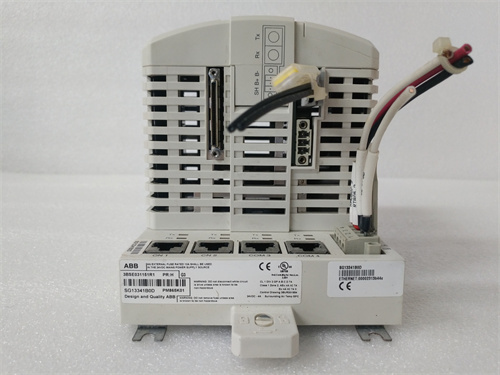

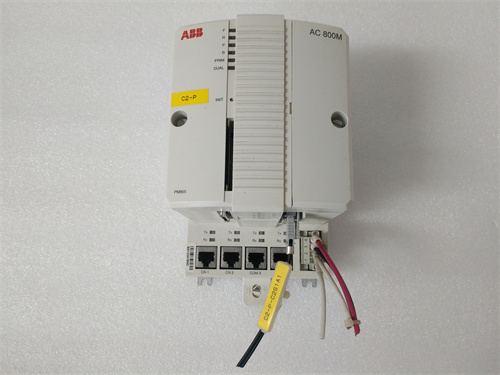

ABB PM866K01 3BSE050198R1is a high-performance processor unit manufactured by ABB,designed for industrial automation and process control applications.This controller module features advanced processing capabilities and robust communication interfaces,making it ideal for demanding industrial environments requiring reliable and efficient control solutions.

Application Scenarios

In a large-scale chemical processing plant in Germany,ABB PM866K01 3BSE050198R1processor units were deployed to upgrade the distributed control system(DCS)managing critical production processes.The existing control system used outdated PLCs that struggled with complex control algorithms and real-time data processing,resulting in production inefficiencies and quality control issues.The system experienced frequent communication timeouts and data loss,leading to unplanned downtime averaging 15 hours per month and production losses exceeding€500,000 annually.

The modernization project involved replacing 32 legacy controllers with PM866K01units configured in redundant pairs across the plant’s key process areas.The modules’133MHz MPC866 processor and 64MB RAM provided the computational power needed for advanced process control algorithms and real-time data acquisition.The dual Ethernet ports enabled seamless integration with the plant’s supervisory control system,while the RS-232C service port facilitated on-site diagnostics and maintenance.The implementation resulted in a 99.8%system availability rate,reducing unplanned downtime by 90%and increasing production throughput by 12%.The improved control precision also enhanced product quality consistency,reducing off-spec production by 25%and generating annual savings of approximately€800,000.

Parameter

Main Parameters

Value/Description

Product Model

PM866K01

Order Number

3BSE050198R1

Manufacturer

ABB

Product Category

Processor Unit

Processor

MPC866,133MHz

Memory

64MB RAM

Ethernet Ports

2 ports

Serial Ports

1×RS-232C,1×RS-232C Service Port

Operating Voltage

24V DC

Power Consumption

5W typical

Operating Temperature

-20°C to+60°C

Storage Temperature

-40°C to+85°C

Dimensions

119mm×135mm×186mm

Weight

1.2kg

Installation

DIN Rail Mount

Protection Rating

IP20

Communication Protocols

Modbus TCP/IP,IEC 61850,OPC UA

Technical Principles and Innovative Values

Innovation Point 1:High-Performance Processing Architecture

ABB PM866K01 3BSE050198R1utilizes the MPC866 PowerPC processor running at 133MHz,providing exceptional computational power for complex control algorithms and real-time data processing.The 64MB RAM ensures sufficient memory for running multiple applications simultaneously,including process control,data logging,and communication tasks.This processing capability enables the controller to handle demanding industrial applications with fast scan times and deterministic performance,critical for time-sensitive control loops in process industries.

Innovation Point 2:Redundant and Fault-Tolerant Design

The module supports redundant configuration with hot standby functionality,ensuring continuous operation even during hardware failures or maintenance activities.The redundant pair automatically synchronizes data and program logic,with seamless switchover in case of primary controller failure.This design minimizes system downtime and protects against production losses,making it ideal for critical process applications where uninterrupted operation is essential.

Innovation Point 3:Advanced Communication Capabilities

PM866K01features dual Ethernet ports supporting multiple industrial protocols including Modbus TCP/IP,IEC 61850,and OPC UA.This multi-protocol support enables seamless integration with various field devices,I/O modules,and supervisory systems.The Ethernet ports support 10/100 Mbps communication speeds,ensuring fast data exchange and real-time control.The RS-232C service port provides local configuration and diagnostics capabilities,while the additional RS-232C port supports legacy devices and serial communication.

Innovation Point 4:Robust Industrial Design

Designed for harsh industrial environments,PM866K01operates reliably in temperatures ranging from-20°C to+60°C and withstands vibration and shock typical in industrial settings.The DIN rail mounting design simplifies installation and maintenance,while the compact form factor saves valuable panel space.The module’s low power consumption(5W typical)reduces heat generation and cooling requirements,contributing to overall system reliability.

Application Cases and Industry Value

Case Study:Power Generation Plant Control System Upgrade

A 500MW combined-cycle power plant in the Netherlands implemented ABB PM866K01 3BSE050198R1processor units to modernize their turbine control system.The existing system used aging controllers that lacked redundancy and modern communication capabilities,resulting in frequent unplanned shutdowns and maintenance challenges.

The upgrade project deployed 16 PM866K01units in redundant pairs to control gas and steam turbines,balance of plant equipment,and auxiliary systems.The controllers’high processing speed enabled faster control loop execution,improving turbine response times during load changes and grid disturbances.The redundant configuration eliminated single points of failure,reducing unplanned shutdowns from 8 per year to zero in the first year of operation.The improved control precision also enhanced plant efficiency by 1.5%,generating annual fuel savings of approximately€450,000.The project achieved a return on investment within 18 months through increased availability and operational efficiency.

Case Study:Pharmaceutical Manufacturing Process Control

A leading pharmaceutical manufacturer in Switzerland integrated ABB PM866K01 3BSE050198R1controllers into their batch process control system for critical drug production lines.The existing system struggled with complex recipe management and batch tracking requirements,leading to compliance issues and production delays.

The implementation involved 24 PM866K01units managing fermentation,purification,and formulation processes.The controllers’64MB RAM capacity supported advanced batch management software and electronic batch record keeping,ensuring full traceability and regulatory compliance.The dual Ethernet ports enabled seamless integration with the plant’s MES(Manufacturing Execution System)and ERP(Enterprise Resource Planning)systems,providing real-time production data and quality metrics.The project resulted in a 30%reduction in batch cycle times,improved product yield by 5%,and achieved FDA and EMA regulatory compliance without any observations during audits.

Related Product Combination Solutions

AC800M Controller Series:The complete controller family that PM866K01belongs to,offering various performance levels and I/O capabilities for different application requirements.

CI867:Ethernet/IP communication module that extends PM866K01’s connectivity options for integration with Rockwell Automation systems and devices.

CI853:PROFIBUS DP communication module that enables PM866K01to interface with PROFIBUS field devices and networks.

CI854:PROFINET IO communication module providing high-speed deterministic communication with PROFINET devices.

TB810:Terminal base unit for PM866K01,providing power supply connections and I/O module interfaces.

SD821:Memory card for PM866K01,used for program storage,data logging,and backup purposes.

SA801:Signal conditioning module that interfaces with analog and digital field signals,extending PM866K01’s I/O capabilities.

Control Builder M:Engineering tool for programming,configuring,and maintaining PM866K01and other AC800M controllers.

Installation,Maintenance,and Full-Cycle Support

Installation and Commissioning

Installing ABB PM866K01 3BSE050198R1is straightforward with its DIN rail mounting design.The module mounts on standard 35mm DIN rails using the integrated mounting clips,requiring no additional tools.Power connections are made to the terminal base unit,which provides 24V DC power and communication interfaces.The module supports hot-swapping in redundant configurations,allowing replacement without system shutdown.Commissioning involves connecting to the controller via Ethernet or the service port,uploading the application program,and configuring communication parameters.The built-in LED indicators provide immediate visual feedback on power,communication,and operational status,simplifying the commissioning process.

Maintenance and Troubleshooting

Routine maintenance for PM866K01is minimal due to its solid-state design and robust construction.Regular checks include verifying LED status indicators,monitoring operating temperature,and reviewing diagnostic logs for any anomalies.The module’s hot-swappable capability allows for replacement during operation in redundant systems,minimizing downtime.Fault diagnosis is facilitated through the built-in diagnostic functions and the service port,which provides detailed status information and error codes.Common maintenance tasks include firmware updates,program backups,and periodic cleaning of ventilation slots to ensure proper cooling.

Technical Support and Service Commitment

ABB provides comprehensive technical support for PM866K01 3BSE050198R1through their global service network.The product is backed by a standard warranty period,with extended warranty options available for critical applications.Technical support includes assistance with system design,integration,commissioning,and troubleshooting.ABB offers training programs for maintenance personnel covering installation procedures,programming,diagnostic techniques,and preventive maintenance practices.Spare parts are available through ABB’s global distribution network with expedited shipping options for urgent requirements.The company also provides field service engineers for on-site support during commissioning or major maintenance activities.Documentation including datasheets,application notes,and technical manuals is available through ABB’s online portal.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: