📄Description

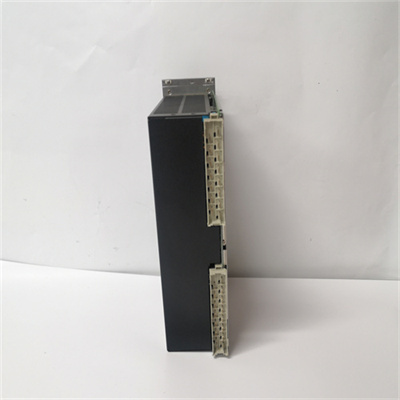

The Vibro-Meter VM600 RLC16 is a 16-channel relay output module designed for the VM600 machinery protection system(MPS)—a high-integrity platform used globally to monitor and protect critical rotating equipment such as steam/gas turbines,compressors,pumps,and generators.

Unlike simple I/O cards,the RLC16 serves as the final control element interface between the VM600’s diagnostic logic and plant safety systems.It converts internal alarm/trip decisions into dry contact relay signals that can:

Trigger emergency shutdown(ESD)valves

Activate horn/strobe alarms

Send trip commands to DCS or PLC

Isolate power to motors or drivers

Interface with fire&gas systems

Each of the 16 relays is typically a form C(SPDT)contact rated for industrial loads(e.g.,250 VAC/2 A resistive),with LED indicators showing real-time status(energized/de-energized).The module supports fail-safe operation:relays de-energize on loss of power or system fault,ensuring safe shutdown per API 670 standards.

The RLC16 mounts into a standard VM600 chassis(e.g.,19″rack with backplane)and communicates with the VM600 CPU module via a high-speed internal bus.It is commonly used alongside vibration input modules(e.g.,VM600 MAA16)and speed modules(VM600 MCS)to form a complete protection system.

⚠️Note:Vibro-Meter is now part of Baker Hughes(formerly GE Measurement&Control,then Baker Hughes a GE Company).The VM600 platform remains actively supported,and the RLC16 is widely deployed in SIL2-rated applications.

🏭Application Scenario

At an LNG export terminal in Qatar,a centrifugal compressor train protected by a VM600 system experienced a bearing failure during startup.The MAA16 vibration module detected abnormal shaft motion and signaled the CPU.Within 8 milliseconds,the RLC16 module de-energized its relays,closing the anti-surge valve and tripping the motor starter via dry contacts.The 16 independent relays also activated local alarms,notified the central DCS,and locked out restart until maintenance cleared the fault.Post-event analysis confirmed the RLC16’s fail-safe design prevented catastrophic rotor seizure—avoiding an estimated$12M in damage and 3-week downtime.The plant now mandates RLC16 modules on all new compression trains due to their reliability and compliance with IEC 61511.

⚙️Technical Parameters

Parameter Value/Description

Model VM600 RLC16(Part No.often:2544016000 or similar)

Manufacturer Vibro-Meter→Now Baker Hughes

Platform VM600 Machinery Protection System

Function 16-channel relay output/alarm logic module

Relay Type SPDT(Form C),electromechanical or solid-state(depending on revision)

Contact Rating 250 VAC/2 A resistive(typical);30 VDC/1 A

Switching Voltage Up to 250 VAC/125 VDC

Isolation Reinforced insulation between channels and logic(≥2.5 kV)

Fail-Safe Behavior Relays de-energize on power loss or fault(configurable in some versions)

Status Indication Per-channel LED(green=energized,off=de-energized)

Backplane Interface Proprietary VM600 high-speed bus

Mounting 19″rack-mounted VM600 chassis(e.g.,8 or 16-slot)

Operating Temperature 0°C to+60°C(industrial grade)

Certifications CE,UL,CSA,ATEX(optional),IEC 61000-6-2/6-4,API 670 compliant

SIL Rating Suitable for SIL2 applications per IEC 61508(when used in full VM600 MPS)

Dimensions Standard VM600 module:~230 mm H×35 mm W×250 mm D

💡Key Features&Value

Safety-Critical Reliability:Designed for zero-failure performance in turbine trip circuits.

API 670 Compliance:Meets mechanical protection standards for petroleum/refining machinery.

Flexible Integration:Dry contacts interface with any DCS,PLC,or hardwired safety system.

Visual Diagnostics:LEDs allow instant verification of alarm/trip states during patrols.

Modular Redundancy:Supports dual-redundant VM600 configurations for ultra-high availability.

🔄Commonly Paired VM600 Modules

CPU:VM600 MPC(Main Processing Card)

Vibration Input:VM600 MAA16(16-channel 4–20 mA or dynamic signal)

Speed Input:VM600 MCS(Multi-Channel Speed)

Analog Output:VM600 DAC16(for trending or secondary systems)

Power Supply:VM600 PSU(Dual redundant optional)

Communication:VM600 COM(Modbus TCP,OPC,or PROFIBUS)

🔧Installation&Maintenance Best Practices

Use shielded cable for relay outputs if routed near sensitive electronics.

Do not exceed contact ratings—use interposing relays for high-current loads.

Test relay operation annually using VM600 built-in diagnostics or manual trip test.

Ensure proper grounding of the VM600 chassis to avoid ground loops.

Keep spare RLC16 modules on-site—critical for rapid recovery after trips.

✅Conclusion

The Vibro-Meter VM600 RLC16 is far more than a relay board—it is the trusted final link between intelligent machine health monitoring and physical plant safety.In high-consequence industries like oil&gas,power generation,and chemical processing,its ability to deliver deterministic,fail-safe trip actions makes it indispensable.

While newer platforms like Bently Nevada 3500 or System 1 offer alternatives,the VM600 RLC16 remains a workhorse in thousands of installations worldwide—many operating continuously for over 15 years.

🔎Note:Baker Hughes continues to supply and support the VM600 platform,including firmware updates and repair services.

📞Contact us for new,refurbished,or tested VM600 RLC16 modules,compatibility checks,or assistance with machinery protection system sustainment or migration.All units undergo contact resistance testing,isolation validation,and include a 24-month warranty.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: