Description

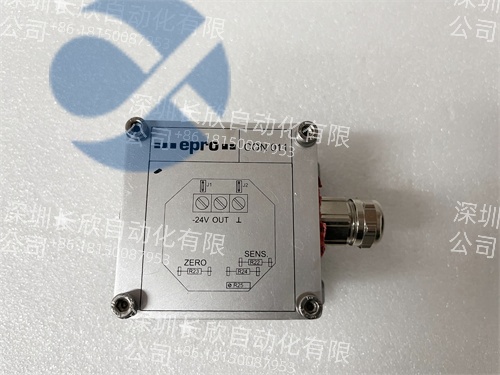

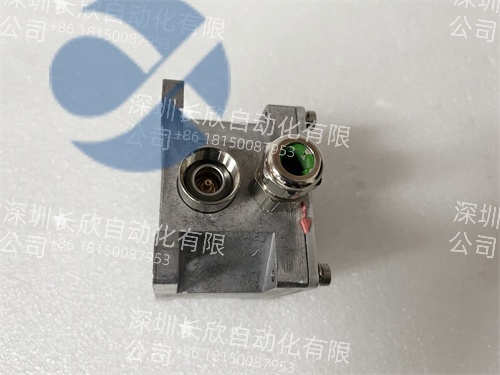

The EPRO PR9376/010-011 is a dual-channel active speed and phase reference sensor designed for precise measurement of rotational speed(RPM)and shaft phase angle(Keyphasor®)in turbines,compressors,pumps,and generators.Unlike passive magnetic pickups,the PR9376 series delivers a clean,amplified 24 VDC square wave output(TTL/CMOS compatible)that remains stable even at zero or very low speeds—making it ideal for startup/shutdown monitoring and slow-roll applications.The/010-011 variant features a 2-meter integrated cable with a MIL-C-5015-style connector and is engineered for direct compatibility with Epro MMS 6000,Vibro-Meter,and third-party protection systems(e.g.,Bentley Nevada 3500).With robust stainless steel construction,wide temperature tolerance,and high immunity to EMI,this sensor ensures reliable operation in demanding environments such as power plants,refineries,and offshore platforms.

Application Scenarios

At a natural gas compressor station in Alberta,operators experienced repeated false alarms from an aging passive magnetic pickup during turbine coast-down.The signal degraded below the threshold of the protection relay,causing missed trips.The team replaced it with an EPRO PR9376/010-011,which provided a clean 24 VDC pulse train down to 0.5 RPM.During the next planned shutdown,the system accurately captured the full deceleration curve,enabling bearing wear analysis via Bode plots.Over 18 months,zero speed-related nuisance alarms occurred.The PR9376/010-011 proved that modern active sensors are not just upgrades—they’re enablers of predictive maintenance.

Parameter

Main Parameters Value/Description

Model EPRO PR9376/010-011

Manufacturer Epro GmbH(now part of Spectris/Brüel&Kjær)

Sensor Type Active,non-contact speed&phase reference probe

Function Dual-channel:Speed+Keyphasor(phase mark detection)

Target Material Ferromagnetic(e.g.,steel gear tooth,keyway,bolt head)

Operating Gap Up to 1.5 mm(0.06 in)from target

Output Signal 24 VDC square wave(open collector or push-pull,TTL/CMOS compatible)

Frequency Range 0.1 Hz to 10 kHz(≈6 RPM to 600,000 RPM)

Supply Voltage 16–30 VDC,reverse polarity protected

Current Consumption<40 mA

Cable Length 2 meters(standard for/010-011 suffix)

Connector MIL-C-5015 circular metal connector(3-pin)

Housing Stainless steel,IP67 rated

Operating Temperature-40°C to+125°C(-40°F to+257°F)

Certifications CE;ATEX optional(specify/Ex variant)

Compatibility Epro MMS 6000,Vibro-Meter VM600,Bentley Nevada 3500(with adapter),SKF IMx

🔍Part Number Breakdown:

PR9376:Product family(active speed/phase sensor)

/010:2 m fixed cable

-011:MIL connector type and standard output configuration

Technical Principles and Innovative Values

Zero-Speed Capability:Unlike passive coils,active electronics generate signal even when shaft is stationary—critical for turning gear monitoring.

Noise Immunity:Differential sensing and shielded cable reject EMI from VFDs,motors,and ignition systems.

Dual-Use Output:One probe provides both speed pulses and once-per-revolution phase reference—reducing installation complexity.

Plug-and-Play Integration:Direct replacement for legacy probes without modifying protection card settings.

Long-Term Stability:No drift due to temperature or aging—ensures consistent trigger point over years.

Application Cases and Industry Value

In a hydroelectric plant in Norway,a Francis turbine required precise phase data for dynamic balancing during commissioning.The existing proximity probe only measured vibration—not speed.Engineers installed an EPRO PR9376/010-011 opposite a single keyway on the shaft.The resulting Keyphasor signal,synchronized with vibration data from eddy-current probes,allowed the team to identify a 2.3 g imbalance at 300 RPM.After correction,bearing temperatures dropped by 18°C,extending overhaul intervals by 3 years.The PR9376 delivered diagnostic-grade timing accuracy at a fraction of laser tachometer cost.

Related Product Combination Solutions

Epro MMS 6810/MMS 6820:Speed&overspeed protection modules

Epro PR6423/PR6424:Eddy-current displacement probes(for vibration)

Bently Nevada 3300 XL:Alternative proximity system

SKF TKSA 71:Laser alignment tool(complementary during balancing)

Vibro-Meter VM600 MOC:Machinery protection chassis

PR9376/020-011:5 m cable version

PR9376/010-011-Ex:ATEX-certified variant for Zone 1

MIL-to-BNC Adapter Cables:For oscilloscope validation

Installation,Maintenance,and Full-Cycle Support

Installation Best Practices:

Mount rigidly using the provided bracket—avoid flexing.

Set air gap to 0.8–1.2 mm using a feeler gauge.

Ensure target has clean,sharp edge(e.g.,machined keyway or bolt head).

Route cable away from high-voltage or motor leads to reduce noise.

Maintenance Tips:

Inspect connector for moisture/corrosion annually.

Verify output waveform with oscilloscope during outages.

Never power the sensor without a load—can damage output stage.

We supply new and factory-refurbished EPRO PR9376/010-011 sensors,each tested for:

✅Output waveform integrity(0–10k Hz sweep)

✅Supply current and short-circuit protection

✅Connector continuity and shielding effectiveness

✅Mechanical integrity(housing,threads,strain relief)

Every unit includes a test certificate and carries a 24-month warranty.We also provide:

Cross-reference charts for Bentley Nevada 21000-16-01 equivalents

Custom cable lengths(3 m,5 m,10 m)

On-site commissioning support for critical machinery

Contact us for a genuine EPRO PR9376/010-011—the trusted choice for accurate,reliable speed and phase detection where machine safety and diagnostics depend on every pulse.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: