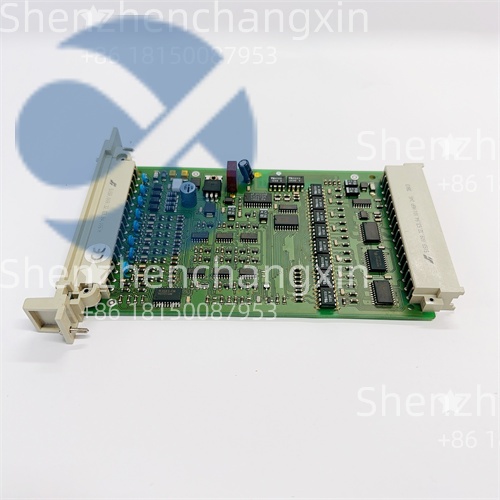

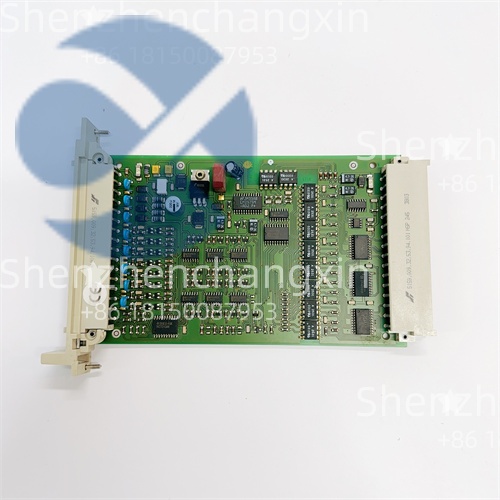

Application Scenarios:Emergency Shutdown(ESD)in an Offshore PlatformOn a large offshore oil and gas production platform,the Emergency Shutdown(ESD)system is the absolute last line of defense against catastrophic events.Hundreds of field devices,such as process pressure high-high switches,gas leak detectors,and manual pushbuttons,feed their status signals into the main safety controller.The reliability of these inputs is non-negotiable.The HIMA LM002_MAX module is the dedicated interface for these inputs.With its high channel density,the LM002_MAX 985020002 allows for efficient wiring of dozens of safety-critical switches into the HIMAX chassis.The module continuously executes internal diagnostics to detect any latent faults,such as wire breakage or short circuits,which could compromise a safety function.If a critical high-high pressure switch is triggered,the LM002_MAX instantly and reliably transmits that signal to the HIMAX CPU,ensuring the controller can execute the necessary trip logic,isolating the equipment,and protecting personnel and the environment.The high integrity of the LM002_MAX is fundamental to achieving the required Safety Integrity Level(SIL 3)for the entire ESD system.Main ParametersParameterValue/DescriptionAnnotationProduct ModelLM002_MAX(985020002)Specific module hardware and firmware identifier.ManufacturerHIMA Paul Hildebrandt GmbHGlobal specialist in functional safety systems.Product CategoryDigital Input Module(DI)High-density I/O for safety-critical inputs.System CompatibilityHIMA HIMAX Safety SystemDesigned for seamless integration into the HIMAX backplane.Channel Capacity$32text{Channels}$High input density per module.Input Signal$24text{V}text{DC}$NominalStandard industrial control voltage.Safety CertificationUp to SIL 3,Cat.4,PL eCertified by TÜV for the highest safety integrity level.Module TypeFail-Safe,Diagnostics-EnabledFeatures continuous self-testing to detect internal/external faults.InstallationSlot-based/ModularMounts directly onto a HIMAX rail/motherboard.Hot-SwappableYesAllows replacement without shutting down the system.Field TerminationVia Separate Terminal ModuleConnects to a dedicated termination module(e.g.,$text{XT}$series).Diagnostic CoverageHigh(Internal/External Faults)Ensures high probability of dangerous fault detection.Technical Principles and Innovative ValuesThe safety integrity of the HIMA LM002_MAX is derived from its advanced digital input technology,distinguishing it from standard industrial I/O:Innovation Point 1:Hardware Diagnostic Coverage:The LM002_MAX 985020002 implements an internal structure that allows it to execute periodic or continuous self-tests without compromising the safety function.This includes testing the input path and the internal logic elements,resulting in a very high Diagnostic Coverage($text{DC}$)critical for achieving SIL 3.Innovation Point 2:High Immunity to Single-Point Failures(1oo2 Architecture):While the entire module is not strictly$1text{oo}2$(One-out-of-Two),the HIMAX system architecture often utilizes internal redundancy techniques at the module level or system level to ensure that a single component failure within the LM002_MAX does not lead to a failure to trip(dangerous failure).Innovation Point 3:Seamless Integration with System Software:The LM002_MAX is tightly integrated with the HIMAX programming environment(ELOP II Factory),allowing engineers to quickly configure input filtering,time stamping,and diagnostics for all 32 channels,simplifying the validation and documentation required for safety systems.Innovation Point 4:Hot-Swappable and Coding System:The module is designed for hot-swapping,minimizing downtime.Furthermore,HIMA employs mechanical or electronic coding to prevent the accidental insertion of an incorrect module type into the LM002_MAX slot,adhering to stringent safety requirements.Application Cases and Industry ValueCase Study:Pipeline Compressor Station Fire and Gas SystemA major pipeline operator utilized the HIMAX system with the HIMA LM002_MAX modules to manage its Fire and Gas(F&G)detection and protection system at a remote compressor station.Application Process:The F&G system required monitoring signals from$100+$heat,smoke,and$text{H}_2text{S}$gas detectors,as well as multiple manual call points.Four HIMA LM002_MAX 985020002 modules handled the discrete alarm status inputs from these detectors.The system was configured for automatic release of suppression agents upon confirmation of two or more independent detector inputs.Improvements and User Feedback:The high-density and highly diagnostic nature of the LM002_MAX significantly reduced the footprint of the safety panel compared to the previous system,saving$30%$of cabinet space.More critically,during a routine functional test,the LM002_MAX diagnostics flagged a”leakage current”fault on a gas detector input channel before the fault became critical.This ability to detect latent,dangerous faults early allowed the maintenance team to replace the faulty field wiring before the F&G system’s safety integrity was compromised.The LM002_MAX’s proactive fault detection directly enhances operational safety and compliance.Related Product Combination SolutionsThe HIMA LM002_MAX is part of the integrated HIMAX platform and works with:HIMA CPU(e.g.,HIMAX CPU):The central processing unit that executes the safety application logic based on the inputs received from the LM002_MAX.1HIMA X-Bus:The high-speed,redundant backplane bus that facilitates communication between the LM002_MAX and the CPU module.HIMA XT Termination Module:The non-electronic,field-wiring termination unit(e.g.,$text{XT}32text{AI}$)that connects field devices to the LM002_MAX via a system cable.HIMA Output Modules(e.g.,LM001_MAX DO):The complementary module used to drive field execution elements(e.g.,solenoid valves,audible alarms)based on the LM002_MAX’s input status.HIMA Power Supply Modules(e.g.,PM001_MAX):Supplies the stabilized$24text{V}$DC power to the HIMAX rack and the LM002_MAX.HIMA Communication Modules(e.g.,CM001_MAX):Used to connect the HIMAX system,including the status of the LM002_MAX channels,to the higher-level DCS or plant network via protocols like Modbus/TCP or OPC UA.Installation,Maintenance,and Full-Cycle SupportThe HIMA LM002_MAX 985020002 is designed for simplified,safety-compliant installation.The module is inserted into the HIMAX sub-rack slot,and its connection to the field is made entirely via a system cable linking the module to a non-electronic terminal block($text{XT}$module).This separation of electronics from field wiring minimizes exposure to field disturbances and simplifies component replacement.The LM002_MAX requires minimal environmental conditioning beyond what is standard for an industrial control cabinet.Routine maintenance is substantially reduced due to the module’s continuous self-diagnostics.The LM002_MAX actively monitors for both internal component failures and external field wiring faults(e.g.,line-monitoring capability).If a fault is detected,the module immediately flags it via the system software and onboard LEDs,allowing for predictive intervention.In the event of a failure,the module’s hot-swappable capability ensures that the system’s safety integrity is maintained during replacement,drastically reducing the$text{Mean Time To Repair(MTTR)}$.Our commitment includes supplying genuine,functionally tested HIMA LM002_MAX 985020002 spare parts,critical for maintaining the safety certification and operational compliance of your HIMAX SIS.Contact us for a strategic spares plan to ensure the maximum safety integrity level of your HIMA HIMAX system.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: