Description

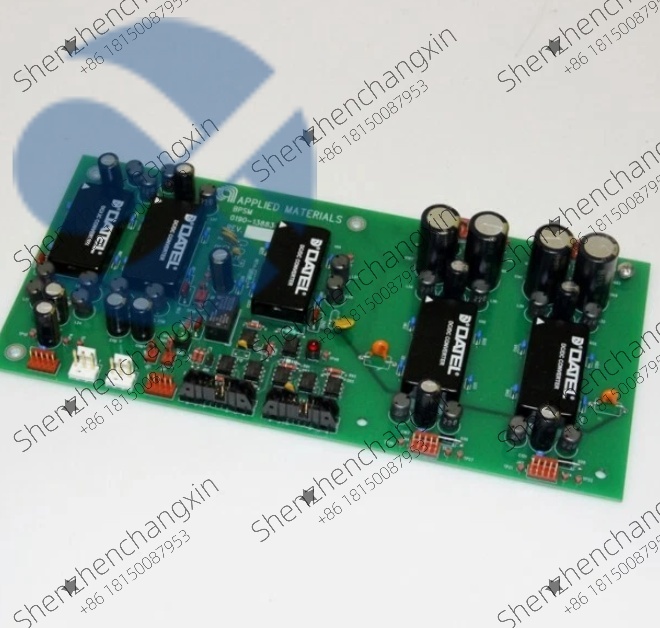

AMAT 0190-37519is a critical printed circuit board assembly(PCBA)manufactured by Applied Materials,Inc.,a global leader in semiconductor manufacturing equipment.This board is a dedicated electronic control or interface module designed for integration into specific Applied Materials wafer processing tools,such as those in the Endura,Centura,or Producer platforms.It performs essential functions ranging from power management and sensor interfacing to digital communication and control logic execution within the tool’s complex subsystems.

Application Scenarios

Inside a state-of-the-art Applied Materials PECVD(Plasma-Enhanced Chemical Vapor Deposition)cluster tool,maintaining precise and repeatable control over thousands of process parameters is non-negotiable.A single subassembly,like a gas delivery module or a chamber isolation valve controller,relies on a dedicated,intelligent board to manage its local actuators,read its sensors,and communicate status back to the tool’s main controller.The AMAT 0190-37519is often the unseen”brain”of such a module.For instance,in a gas panel,this board might precisely control multiple solenoid valves and mass flow controllers based on recipes downloaded from the host,while continuously monitoring for leaks via pressure transducers.Its failure could cause a”Module Communication Fault”or”Gas Flow Error,”instantly halting production and potentially scrapping a full lot of high-value wafers.A senior equipment engineer at a leading logic fab noted,”When our wafer throughput started dropping due to intermittent faults in a precursor delivery module,diagnostics pointed to the 0190-37519board.Swapping it with a certified spare from our strategic stock was the difference between a 4-hour recovery and a potential multi-day downtime event waiting for a part.This board’s reliability directly impacts our tool’s overall equipment effectiveness(OEE).”

Parameter

Main Parameters

Value/Description

Product Model

0190-37519

Manufacturer

Applied Materials,Inc.(AMAT)

Product Category

Printed Circuit Board Assembly(PCBA)/Control Module

Board Type

Multi-layer,likely 4-8 layers,with industrial-grade components.

Core Functions

Likely includes power conversion,digital I/O,analog signal conditioning,communication control.

Microcontroller/DSP

Contains a dedicated processor for executing embedded control firmware.

Communication Interfaces

Integrated with tool’s proprietary bus(e.g.,CAN,DeviceNet,RS-485)or Ethernet.

Inputs/Outputs

Multiple channels for connecting sensors(temp,pressure,analog)and actuators(valves,relays).

Power Input

Typically receives a low-voltage DC supply(e.g.,+24V,±15V,+5V)from the tool’s main PSU.

Environmental Rating

Designed for controlled cleanroom or subfab environments(low particulate,controlled temp).

Installation

Plugs into a dedicated slot or connects via cables within a specific tool sub-module.

Firmware

Runs Applied Materials-proprietary embedded software,often board-specific.

Technical Principles and Innovative Values

Innovation Point 1:Application-Specific Integrated Design for Deterministic Performance

The AMAT 0190-37519is not a generic computing board;it is a purpose-built electronic system engineered for a specific control task within a semiconductor tool.Its value lies in its optimized integration.The PCB layout,component selection(using extended temperature range and high-reliability parts),and onboard firmware are all co-designed to meet stringent performance criteria:deterministic response times for closed-loop control,ultra-low noise on analog measurement circuits,and flawless communication over the tool’s real-time network.This level of integration ensures that a gas valve opens exactly when commanded within microseconds or a temperature reading is accurate to a fraction of a degree,which is paramount for process uniformity and yield.

Innovation Point 2:Comprehensive Diagnostics and Predictive Data Logging

A key feature of modern AMAT control boards like the 0190-37519is their embedded intelligence for health monitoring.Beyond basic control,the board continuously performs self-diagnostics,monitoring its internal voltages,temperatures,and the status of connected peripherals.It logs performance data and error precursors.This information is accessible to the tool’s diagnostics software,enabling predictive maintenance.For example,the board might report a gradual increase in the current required to drive a solenoid valve,signaling impending failure before it causes a process excursion.This transforms the board from a simple control device into a proactive asset management node,reducing unplanned downtime.

Innovation Point 3:Robust Communication and Firmware Integrity

Reliable integration into the tool’s ecosystem is critical.The 0190-37519implements robust communication protocols to ensure error-free data exchange with the host controller,even in the electrically noisy environment of a plasma tool.The board’s firmware is designed for high integrity,often featuring checksums,watchdog timers,and safe recovery routines.In the event of a communication glitch or power anomaly,the board is designed to fail safely or recover gracefully without corrupting the process or requiring a manual reset,thereby maximizing tool availability.

Application Cases and Industry Value

Case Study:Enhancing Uptime in a Dielectric Etch Chamber

A major memory chip manufacturer was experiencing sporadic,hard-to-diagnose faults in one of its Applied Materials dielectric etch chambers.The faults,manifesting as”RF Match Tuning Errors”and”Chamber Pressure Fluctuations,”would cause the tool to pause for recovery,impacting throughput.Deep-dive analysis by Applied Materials field engineers,using advanced tool logs,traced the root cause not to the RF generator or pressure sensor itself,but to intermittent signal corruption from the 0190-37519board that acted as the local controller and interface for the chamber’s auxiliary systems,including the foreline valve and some diagnostic sensors.

The 0190-37519in this application was responsible for aggregating signals from several analog sensors and driving small actuators.Investigation revealed that noise on a specific power rail on the aging board was causing bit errors in the analog-to-digital conversion,leading to erroneous pressure readings and confused control responses.Replacing the 0190-37519board with a new,certified unit from their critical spares inventory resolved the issue immediately.The impact was significant:1.Elimination of Chronic Faults:The intermittent errors disappeared,restoring predictable tool operation.2.5%Increase in Chamber Uptime:The reduction in unscheduled pauses directly improved the tool’s productive capacity.3.Avoided Costly Process Excursions:By preventing faulty sensor data from influencing the etch recipe,potential wafer scrap worth hundreds of thousands of dollars was avoided.The fab’s equipment manager concluded,”The 0190-37519was a relatively small component cost-wise,but its function was absolutely vital.Identifying and replacing it turned a chronic,productivity-sapping problem into a non-issue.It reinforced our strategy of maintaining strategic spares for key electronic modules.”

Related Product Combination Solutions

AMAT Power Supply Units(e.g.,0190-xxxxx):Provide the clean,regulated DC power required by the 0190-37519and other boards in the module.

AMAT I/O Extender Boards:May be used in conjunction with the 0190-37519to expand its digital or analog channel count for larger subassemblies.

AMAT Communication Hub Boards:Act as a network concentrator,linking multiple modules like the one containing the 0190-37519to the tool’s main controller.

Applied Materials Factory Interface Boards:Control the robotic handling of wafers between chambers;the 0190-37519may control subsystems within this domain.

AMAT Sensor&Actuator Kits:Include the pressure transducers,thermocouples,or solenoid valves that are directly connected to and controlled by the 0190-37519board.

Applied Materials Gas Flow Controller(e.g.,UFC):A higher-level module for which the 0190-37519might serve as a local digital controller or interface.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: