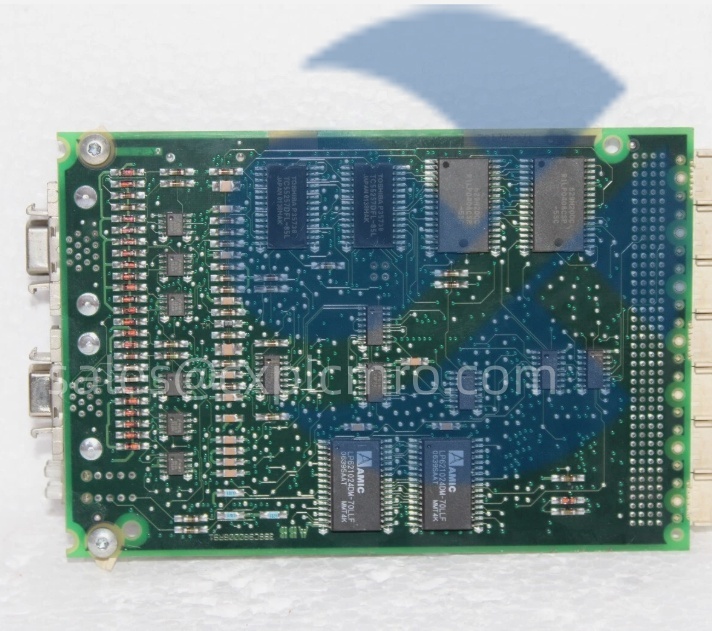

Product Description

Brand:ABB

Model:CI522A

Part Number:3BSE018283R1

Fieldbus Designation:AF100

Function:Ethernet Communication Interface Module

Protocol:AF100(ABB Fieldbus)over standard IEEE 802.3 Ethernet

ABB CI522A 3BSE018283R1(AF100)is a core Ethernet communication interface modulefor the ABB AC800Mcontroller series.It provides the physical and data link layer for ABB’s deterministic AF100fieldbus network,enabling high-speed,cyclic I/O data exchange between the AC800M controller and distributed I/O stations(S800 I/O).It uses standard Ethernet hardware(RJ-45,CAT5e)to deliver a robust,high-performance network backbone for process automation.Genuine ABB component,essential for building scalable and reliable distributed control architectures.

Application Scenarios

In a sprawling wastewater treatment plant,the central control room houses the master AC800M PM861controller,but critical sensors and actuators are distributed over miles:dissolved oxygen probes in aeration tanks,pH sensors in clarifiers,and large pump motor starters in remote pumping stations.Running individual cables for each signal to the central room is cost-prohibitive and a maintenance nightmare.This is where the ABB CI522A 3BSE018283R1module proves its worth.Installed in the central controller rack,it acts as the AF100 network master.Over a single,redundant fiber-optic Ethernet ring,it communicates with dozens of remote S800 I/O stationsequipped with their own communication interfaces.The CI522Amanages deterministic cyclic data exchange,ensuring that every millisecond,valve positions are read and new pump speeds are written,with guaranteed latency.During a storm,a lightning strike damages a network segment.The CI522A’s support for media redundancy protocols(like MRP)ensures the network reconfigured in<500ms,using the alternate fiber path,and the control system never missed a scan.For the plant engineer,the reliability of the CI522Amodule translates directly to environmental compliance and operational continuity;it is the unwavering digital nervous system that connects the control brain to every muscle and sensory organ of the facility.

Key Parameters

Parameter

Value/Description

Product Model

CI522A

Manufacturer Part Number

3BSE018283R1

Fieldbus Type

AF100(ABB Automation Fieldbus 100)over Ethernet

Manufacturer

ABB

Product Type

Communication Interface Module(Network Master)

Compatible Controller

ABB AC800M Controller Series(e.g.,PM861,PM864,PM866)

Physical Interface

2 x 10/100 Mbps RJ-45 Ethernet ports(copper).Often used with media converters for fiber optic cabling.

Network Topology

Supports line,star,tree,and ring topologies.Redundant ring(with MRP)is standard for high availability.

Protocol Standard

Uses IEEE 802.3 Ethernet at layers 1&2.Implements ABB’s deterministic AF100 protocol for cyclic I/O data.

Cyclic Data Update

Configurable cycle times,typically down to 1 ms for critical I/O,enabling high-speed control.

Number of Stations

Can support a large number of S800 I/O stations(e.g.,up to 100+per network segment,depending on configuration).

Configuration

Configured entirely within ABB Control Builderengineering software.

Status Indication

Comprehensive LEDs for module status,network A/B activity,link status,and errors.

Power Supply

Powered directly from the AC800M controller’s backplane.

Redundancy

Supports network redundancy via Media Redundancy Protocol(MRP).Communication modules can also be configured in redundant pairs.

Primary Role

Provides the deterministic,high-speed network backbone for connecting an AC800M controller to its distributed S800 I/O.

Technical Principles and Innovative Values

The ABB CI522A 3BSE018283R1is a masterpiece of applied networking,taking the ubiquitous,non-deterministic Ethernet standard and molding it into a rock-solid,deterministic backbone for mission-critical process control.Its innovation lies in its layered approach to reliability and performance.

Innovation Point 1:Deterministic AF100 Protocol over Standard Ethernet Hardware

The core innovation of the CI522Aand the AF100 system is the implementation of a time-slicing,token-passing mechanismon top of standard IEEE 802.3 Ethernet.While using standard cables and switches,the AF100 protocol organizes network traffic into precise,repeating cycles.Within each cycle,time is allocated for cyclic I/O data(deterministic,high priority),acyclic parameter data(engineering,configuration),and TCP/IP traffic(for non-time-critical data like file transfer).The CI522Amodule,as the master,orchestrates this schedule.This guarantees that critical process data—like a valve command or a safety interlock—is transmitted and received within a strict,predictable timeframe(e.g.,10ms),regardless of other network traffic.This deterministic performance is what separates it from standard Industrial Ethernet where I/O traffic competes equally with other data,making it ideal for fast,complex regulatory control loops.

Innovation Point 2:Comprehensive High-Availability and Redundancy Features

The module is engineered for zero single points of failure.It features two independent Ethernet portsthat can be configured in a redundant ring topologyusing the Media Redundancy Protocol(MRP).If a cable is cut or a switch fails,the network reconfigures itself within milliseconds,ensuring continuous communication.Furthermore,the CI522Amodule itself can be deployed in a redundant pair(1:1 redundancy).A primary and standby module work in tandem;the standby monitors the primary’s health and network activity.If the primary fails,the standby assumes the master role seamlessly,with no loss of configured connections or data.This dual-level redundancy(network and module)is critical for applications in power generation,oil&gas,and other industries where unplanned downtime is catastrophic.

Innovation Point 3:Superior Diagnostics and Seamless Engineering Integration

The module provides an exceptional level of visibility into network health.From within Control Builder,engineers can view real-time diagnostics:cycle load,station status,error counters per station,and detailed event logs.Each port has clear LED indicators for link,activity,and errors,allowing quick visual fault localization.Configuration is entirely graphical and integrated;defining the network,adding stations,and mapping I/O is done in the same project as the control logic.The system automatically calculates the network cycle time and validates configuration consistency.This tight integration eliminates the common pitfalls of separate network configuration tools,reducing engineering errors and commissioning time.

Innovation Point 4:Scalability and Future-Proof Design

The AF100 network using the CI522Ais highly scalable.A single network can grow to incorporate a large number of I/O stations distributed over long distances(using fiber optics),making it suitable for everything from a compact machine to an entire process plant.The use of standard Ethernet as the physical layer future-proofs the investment.It allows for easy integration of network diagnostics tools and leverages the vast ecosystem of Ethernet cabling,connectors,and switches,while the deterministic AF100 protocol on top ensures the performance needed for control.This hybrid approach gives the best of both worlds:open standards for infrastructure and a optimized,reliable protocol for control.

Application Cases and Industry Value

Case Study:Pulp&Paper Mill Distributed Control System Modernization

A century-old pulp mill was modernizing its batch digester and paper machine control systems.The existing system used miles of legacy wiring and slow serial networks,causing unpredictable latency,difficult troubleshooting,and high maintenance costs.The goal was to improve product quality consistency,reduce energy consumption,and enable advanced process optimization.

The solution centered on a new ABB Ability™System 800xADCS,with AC800Mcontrollers using CI522Amodules as the network core.Over 50 remote S800 I/Opanels were installed directly near the process equipment:on the paper machine floor,in the bleach plant,and beside the recovery boiler.Each was connected via a redundant fiber-optic ring managed by the CI522Amodules.

The impact was transformative:1.Unprecedented Data Integrity&Speed:The deterministic sub-100ms scan time of the AF100network via the CI522Aallowed for tighter control loops.The paper machine’s basis weight profile could be controlled with far greater precision,reducing product variation by 15%.2.Drastic Reduction in Wiring&Commissioning Time:The distributed I/O architecture,enabled by the robust network,cut overall project cable costs by an estimated 40%and reduced commissioning loop-check time by 60%.3.Enhanced Operational Insight:The rich diagnostics of the CI522Anetwork allowed maintenance to predict switch or module failures.In one instance,increasing error counts on a specific network segment alerted technicians to a failing media converter beforeit caused an outage,preventing a 4-hour production loss on the paper machine.The mill’s engineering manager summarized:”The reliability of the CI522Anetwork is now something we take for granted.It’s the invisible,flawless pipeline that carries all our control intelligence.It was the foundational upgrade that made all other advanced controls and analytics possible.”

Related Product Combination Solutions

The CI522Ais the centerpiece of the AC800M’s distributed I/O network.Its operation is interdependent with:

ABB AC800M Controller(e.g.,PM861,PM864):The CPU that hosts the CI522Amodule and executes the control logic using the I/O data it provides.

ABB S800 I/O Stations:The remote I/O units(e.g.,TU847,TU849actuator interfaces)that house the actual I/O modules.They connect to the AF100 network via their own communication modules(like CI854for redundant AF100).

ABB S800 I/O Modules:The digital/analog input and output cards(e.g.,DI801,AI810,DO810,AO810)that interface with field devices,installed in the S800 stations.

ABB Control Builder Professional/Plus:The mandatory engineering software used to configure the hardware,network,and control applications.

Industrial Ethernet Switches&Media Converters:Managed switches that support MRP for building redundant rings.Media converters(fiber to copper)for long-distance or electrically noisy connections.

CI522A Redundancy Kit:The necessary cabling and termination accessories to configure a redundant pair of CI522Amodules.

ABB Advant Fieldbus 100(AF100)Cables&Connectors:Specialized,ruggedized cables and connectors designed for the deterministic timing requirements of the AF100 protocol,though standard CAT5e/6 can be used in benign environments.

Installation,Maintenance,and Full-Cycle Support

Installation&Network Planning:The CI522Amodule slides into a free slot in the AC800M controller rack.Critical pre-work is network design:Plan the topology(ring recommended),calculate the cycle time based on the number of stations and I/O points,and select appropriate network equipment(MRP-capable switches).Use high-quality,shielded Ethernet cables and ensure proper grounding.For long distances or harsh environments,use fiber optic media converters.When installing a redundant pair,follow the specific cabling diagram to connect the primary and standby modules correctly.

Configuration&Commissioning in Control Builder:

Hardware Configuration:Add the CI522Amodule to the controller’s hardware layout.Configure its parameters:set it as the network master,define the network name,and set the target cycle time.

Network Configuration:In the network view,add all remote S800 I/O stations.Assign each a unique station address.The software will automatically build the network configuration and calculate the actual achievable cycle time.

I/O Mapping:For each I/O channel in the remote stations,map it to a variable in the controller(e.g.,%IW,%QW).This creates the link between the physical field point and the logic.

Download&Test:Download the complete configuration to the controller.The CI522Awill establish the network.Use the online diagnostics in Control Builder to verify that all stations are in”OK”status.Perform loop checks by forcing I/O points and verifying field device response.

Routine Maintenance&Diagnostics:The module requires no periodic maintenance.The primary task is monitoring.Regularly check the LED status indicators(all should be steady green under normal operation).Use the network diagnostics in Control Builder to review error logs and station statistics during planned shutdowns.Keep a known-good spare CI522Amodule on site for critical applications.Network health can also be monitored via SNMP if the underlying Ethernet switches support it.

Troubleshooting:A red fault LED on the module indicates a hardware or severe configuration error.Check the backplane connection and power.If a station is missing from the network,use the”Station Status”view in Control Builder to see the last known state and error code.Common issues are incorrect station addresses,faulty cables,or a break in a ring network where MRP is not properly configured on all switches.

Our Commitment:We supply 100%genuine,factory-tested ABB CI522A 3BSE018283R1communication modules.Each unit is tested for basic functionality and Ethernet port integrity.We provide a 12-month warranty.Our technical experts,familiar with AF100 network design,can offer guidance on topology selection,cycle time calculation,and redundancy configuration to ensure your distributed control system is built on a foundation of reliability.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: