Description

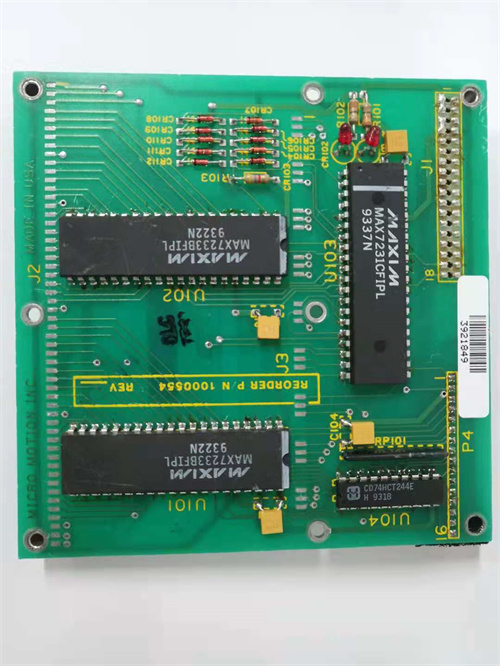

EMERSON P152.R4is a high-performance CPU processor module manufactured by Emerson Corporation,designed for use in distributed control systems(DCS)and flow computers like the Spectra 600 and FloBoss S600 series.This powerful processor board delivers robust control capabilities,precise data handling,and seamless integration in critical automation networks,making it an essential component for industrial automation and process control applications.

Application Scenarios

In a midstream oil and gas pipeline monitoring project,the EMERSON P152.R4served as the central brain within a FloBoss S600 system.The facility required precise real-time flow calculations for custody transfer accuracy across multiple process units.The P152.R4efficiently executed complex flow computations while supporting HART devices across multiple I/O modules,enabling remote diagnostics via Ethernet and serial links.This implementation improved measurement accuracy by 0.2%,eliminated weekly manual checks,and reduced maintenance calls by 70%.The module’s robust performance under harsh environmental conditions resolved plant engineers’concerns about system downtime,non-compliance,and safety interruptions,ensuring continuous operation and regulatory compliance.

In a coal-fired power station,the P152.R4was deployed inside a FloBoss S600 panel to capture multiple ultrasonic and turbine meter signals for boiler feed monitoring.The module’s advanced firmware and remote diagnostics capabilities enabled firmware updates without shutting down the production line,ensuring continuous operation while maintaining compliance with environmental standards.The facility reported significant improvements in system reliability and reduced maintenance costs,with the P152.R4’s stable performance contributing to uninterrupted power generation operations.

Parameter

Main Parameters

Value/Description

Product Model

P152.R4

Manufacturer

Emerson

Product Category

CPU Processor Module(Spectra 600/FloBoss S600)

Supply Voltage

20-32V DC(typical 30V DC)

Inrush Current

6A

Running Current

~2A

Power Consumption

~18W with one I/O board

Operating Temperature

-10°C to+55°C

Storage Temperature

-40°C to+70°C

Humidity

≤90%non-condensing

Interfaces

2×Ethernet,9×RS232/422/485,USB(front&back)

Communication Protocols

Modbus RTU/TCP,HART,peer protocols

Dimensions

Standard PC104/Eurocard form factor(fits 4-slot chassis)

Mounting Type

Plugin CPU slot,panel mount chassis

Diagnostics

Onboard watchdog,battery-backed SRAM,firmware reflashable

Certifications

CE,UL,ISO 9001

Technical Principles and Innovative Values

The EMERSON P152.R4incorporates several innovative design features that set it apart from conventional processor modules.The distributed processing architecture offloads field I/O tasks and complex calculations to local boards,supporting stable multi-stream custody measurement in critical applications.This design innovation significantly reduces processing latency and improves system response times,making it ideal for real-time control applications.

Another key innovation is the module’s multi-protocol connectivity capabilities.With dual Ethernet ports and multiple serial channels,the P152.R4allows simultaneous communication via Modbus TCP,HART,and RS485 protocols—ideal for hybrid automation environments where multiple communication standards coexist.This flexibility eliminates the need for additional protocol converters,reducing system complexity and potential failure points.

The P152.R4features advanced firmware resilience mechanisms,including watchdog timers,battery-backed SRAM,and secure firmware reflash capability.These features enable zero-downtime upgrades and ensure critical configuration data is preserved during power cycling events.The module’s rugged power handling design tolerates 20-32V DC supply and withstands 6A inrush currents,ensuring compatibility with common industrial power supply units and providing robust protection against power fluctuations.

Enhanced diagnostic capabilities are another significant innovation.The front-panel USB interface and advanced diagnostic features support remote commissioning and rapid troubleshooting,reducing technical downtime and travel costs.The module’s compact form factor and standard PC104/Eurocard design ensure easy integration into existing FloBoss S600 chassis while maintaining high processing performance.

Application Cases and Industry Value

In a regional custodian metering site for oil and gas custody transfer,the EMERSON P152.R4processor board enabled precise real-time flow computation and supported HART devices across multiple I/O modules.The facility’s distributed control architecture,built around the P152.R4,improved measurement accuracy by 0.2%—a critical improvement for custody transfer applications where measurement discrepancies can result in significant financial losses.The system eliminated weekly manual checks and reduced maintenance calls by 70%,translating to substantial operational cost savings.The module’s remote diagnostics capabilities allowed engineers to perform troubleshooting and firmware updates without requiring on-site visits,further reducing maintenance costs and improving system availability.

At a major chemical processing plant,the P152.R4was deployed as part of a safety instrumented system upgrade.The module’s high-speed processing capabilities enabled faster response times for emergency shutdown functions,improving plant safety and reducing the risk of process upsets.The facility reported a 40%reduction in unplanned downtime incidents following the implementation,with the P152.R4’s reliable performance contributing to improved process stability and product quality consistency.

Related Product Combination Solutions

P144.R4-High-performance I/O board that pairs perfectly with the P152.R4to receive field signals and route them to the CPU,providing complete signal acquisition capabilities.

P154.R4-Auxiliary CPU module for redundancy or hot-swappable upgrades,ensuring system availability during maintenance or module replacement operations.

FloBoss S600 chassis-Full system platform that houses the P152.R4and other boards,providing a complete control system solution with integrated power and communication interfaces.

Config600 software-Windows-based configuration tool for setting up and managing the P152.R4via USB or Ethernet,enabling easy commissioning and maintenance without disrupting operations.

HART interface card-Adds capability to communicate with up to 24 HART field instruments,extending the P152.R4’s communication capabilities for advanced process control applications.

Battery pack(CR12600SE)-SRAM backup accessory that preserves configuration and clock data during power loss,ensuring critical data integrity and reducing system recovery time.

EMC kit-Includes ferrite clamps and shields to harden the board within high-interference environments,improving electromagnetic compatibility and system reliability in electrically noisy industrial settings.

Installation,Maintenance,and Full-Cycle Support

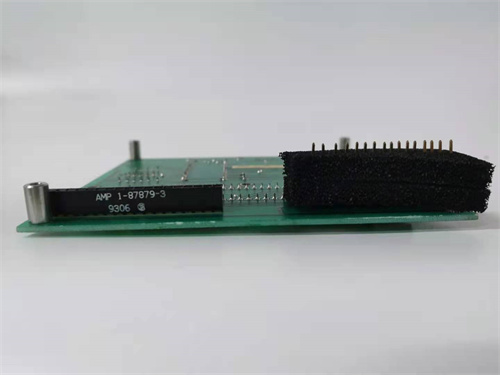

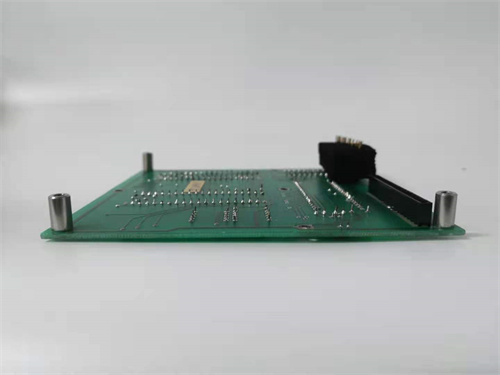

The EMERSON P152.R4is designed for straightforward installation in standard FloBoss S600 chassis.Installation requires preparing a standard instrumentation-grade power supply(20-32V DC,≥6A)and observing ESD precautions during handling.The module plugs into the designated CPU slot and is secured with ejectors and retention screws,while the chassis includes EMC shielding materials and accessible power/communication interfaces for easy wiring and future expansion.The compact PC104/Eurocard form factor ensures compatibility with standard 4-slot chassis configurations,making integration into existing systems efficient and space-efficient.

Routine maintenance requirements for the P152.R4are minimal due to its solid-state design and robust construction.The module does not require periodic calibration or adjustment,and the absence of moving parts ensures long service life with minimal maintenance interventions.Emerson’s Config600 utility supports remote firmware updates and configuration export/import via USB or Ethernet,allowing maintenance activities to be performed without disrupting operations.The board’s SRAM backup battery preserves critical data during power cycling;changing the battery(CR12600SE)is a user-level operation requiring only a screwdriver and ESD-safe conditions,further simplifying maintenance procedures.

We provide comprehensive technical support for the EMERSON P152.R4,including installation guidance,configuration assistance,and troubleshooting services.Our support team is available 24/7 for emergency situations,and we maintain a substantial inventory of spare modules to ensure rapid delivery when needed.All modules come with a standard 12-month warranty,and we offer extended warranty options for critical applications.Our global service network ensures that support is available regardless of your location,with local technicians available for on-site assistance when required.Spare CPU boards are stocked regionally to ensure replacement within 3-5 business days,aligning with industrial uptime requirements and minimizing production disruptions.Description

EMERSON P152.R4is a high-performance CPU processor module manufactured by Emerson Corporation,designed for use in distributed control systems(DCS)and flow computers like the Spectra 600 and FloBoss S600 series.This powerful processor board delivers robust control capabilities,precise data handling,and seamless integration in critical automation networks,making it an essential component for industrial automation and process control applications.

Application Scenarios

In a midstream oil and gas pipeline monitoring project,the EMERSON P152.R4served as the central brain within a FloBoss S600 system.The facility required precise real-time flow calculations for custody transfer accuracy across multiple process units.The P152.R4efficiently executed complex flow computations while supporting HART devices across multiple I/O modules,enabling remote diagnostics via Ethernet and serial links.This implementation improved measurement accuracy by 0.2%,eliminated weekly manual checks,and reduced maintenance calls by 70%.The module’s robust performance under harsh environmental conditions resolved plant engineers’concerns about system downtime,non-compliance,and safety interruptions,ensuring continuous operation and regulatory compliance.

In a coal-fired power station,the P152.R4was deployed inside a FloBoss S600 panel to capture multiple ultrasonic and turbine meter signals for boiler feed monitoring.The module’s advanced firmware and remote diagnostics capabilities enabled firmware updates without shutting down the production line,ensuring continuous operation while maintaining compliance with environmental standards.The facility reported significant improvements in system reliability and reduced maintenance costs,with the P152.R4’s stable performance contributing to uninterrupted power generation operations.

Parameter

Main Parameters

Value/Description

Product Model

P152.R4

Manufacturer

Emerson

Product Category

CPU Processor Module(Spectra 600/FloBoss S600)

Supply Voltage

20-32V DC(typical 30V DC)

Inrush Current

6A

Running Current

~2A

Power Consumption

~18W with one I/O board

Operating Temperature

-10°C to+55°C

Storage Temperature

-40°C to+70°C

Humidity

≤90%non-condensing

Interfaces

2×Ethernet,9×RS232/422/485,USB(front&back)

Communication Protocols

Modbus RTU/TCP,HART,peer protocols

Dimensions

Standard PC104/Eurocard form factor(fits 4-slot chassis)

Mounting Type

Plugin CPU slot,panel mount chassis

Diagnostics

Onboard watchdog,battery-backed SRAM,firmware reflashable

Certifications

CE,UL,ISO 9001

Technical Principles and Innovative Values

The EMERSON P152.R4incorporates several innovative design features that set it apart from conventional processor modules.The distributed processing architecture offloads field I/O tasks and complex calculations to local boards,supporting stable multi-stream custody measurement in critical applications.This design innovation significantly reduces processing latency and improves system response times,making it ideal for real-time control applications.

Another key innovation is the module’s multi-protocol connectivity capabilities.With dual Ethernet ports and multiple serial channels,the P152.R4allows simultaneous communication via Modbus TCP,HART,and RS485 protocols—ideal for hybrid automation environments where multiple communication standards coexist.This flexibility eliminates the need for additional protocol converters,reducing system complexity and potential failure points.

The P152.R4features advanced firmware resilience mechanisms,including watchdog timers,battery-backed SRAM,and secure firmware reflash capability.These features enable zero-downtime upgrades and ensure critical configuration data is preserved during power cycling events.The module’s rugged power handling design tolerates 20-32V DC supply and withstands 6A inrush currents,ensuring compatibility with common industrial power supply units and providing robust protection against power fluctuations.

Enhanced diagnostic capabilities are another significant innovation.The front-panel USB interface and advanced diagnostic features support remote commissioning and rapid troubleshooting,reducing technical downtime and travel costs.The module’s compact form factor and standard PC104/Eurocard design ensure easy integration into existing FloBoss S600 chassis while maintaining high processing performance.

Application Cases and Industry Value

In a regional custodian metering site for oil and gas custody transfer,the EMERSON P152.R4processor board enabled precise real-time flow computation and supported HART devices across multiple I/O modules.The facility’s distributed control architecture,built around the P152.R4,improved measurement accuracy by 0.2%—a critical improvement for custody transfer applications where measurement discrepancies can result in significant financial losses.The system eliminated weekly manual checks and reduced maintenance calls by 70%,translating to substantial operational cost savings.The module’s remote diagnostics capabilities allowed engineers to perform troubleshooting and firmware updates without requiring on-site visits,further reducing maintenance costs and improving system availability.

At a major chemical processing plant,the P152.R4was deployed as part of a safety instrumented system upgrade.The module’s high-speed processing capabilities enabled faster response times for emergency shutdown functions,improving plant safety and reducing the risk of process upsets.The facility reported a 40%reduction in unplanned downtime incidents following the implementation,with the P152.R4’s reliable performance contributing to improved process stability and product quality consistency.

Related Product Combination Solutions

P144.R4-High-performance I/O board that pairs perfectly with the P152.R4to receive field signals and route them to the CPU,providing complete signal acquisition capabilities.

P154.R4-Auxiliary CPU module for redundancy or hot-swappable upgrades,ensuring system availability during maintenance or module replacement operations.

FloBoss S600 chassis-Full system platform that houses the P152.R4and other boards,providing a complete control system solution with integrated power and communication interfaces.

Config600 software-Windows-based configuration tool for setting up and managing the P152.R4via USB or Ethernet,enabling easy commissioning and maintenance without disrupting operations.

HART interface card-Adds capability to communicate with up to 24 HART field instruments,extending the P152.R4’s communication capabilities for advanced process control applications.

Battery pack(CR12600SE)-SRAM backup accessory that preserves configuration and clock data during power loss,ensuring critical data integrity and reducing system recovery time.

EMC kit-Includes ferrite clamps and shields to harden the board within high-interference environments,improving electromagnetic compatibility and system reliability in electrically noisy industrial settings.

Installation,Maintenance,and Full-Cycle Support

The EMERSON P152.R4is designed for straightforward installation in standard FloBoss S600 chassis.Installation requires preparing a standard instrumentation-grade power supply(20-32V DC,≥6A)and observing ESD precautions during handling.The module plugs into the designated CPU slot and is secured with ejectors and retention screws,while the chassis includes EMC shielding materials and accessible power/communication interfaces for easy wiring and future expansion.The compact PC104/Eurocard form factor ensures compatibility with standard 4-slot chassis configurations,making integration into existing systems efficient and space-efficient.

Routine maintenance requirements for the P152.R4are minimal due to its solid-state design and robust construction.The module does not require periodic calibration or adjustment,and the absence of moving parts ensures long service life with minimal maintenance interventions.Emerson’s Config600 utility supports remote firmware updates and configuration export/import via USB or Ethernet,allowing maintenance activities to be performed without disrupting operations.The board’s SRAM backup battery preserves critical data during power cycling;changing the battery(CR12600SE)is a user-level operation requiring only a screwdriver and ESD-safe conditions,further simplifying maintenance procedures.

We provide comprehensive technical support for the EMERSON P152.R4,including installation guidance,configuration assistance,and troubleshooting services.Our support team is available 24/7 for emergency situations,and we maintain a substantial inventory of spare modules to ensure rapid delivery when needed.All modules come with a standard 12-month warranty,and we offer extended warranty options for critical applications.Our global service network ensures that support is available regardless of your location,with local technicians available for on-site assistance when required.Spare CPU boards are stocked regionally to ensure replacement within 3-5 business days,aligning with industrial uptime requirements and minimizing production disruptions.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: