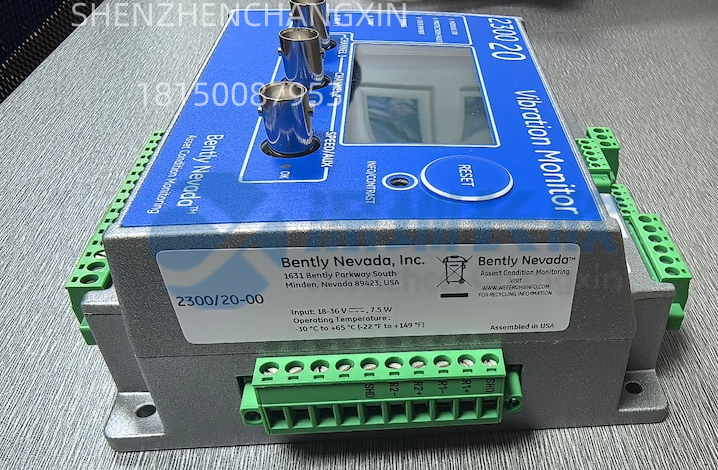

Product Description

Description:

The BENTLY 2300/25-00is a dedicated power supply module for Bently Nevada’s 2300 series proximity transducer systems.It provides a highly stable and regulated-24 VDC excitation voltage required to power eddy current proximity probes.Designed for industrial environments,this module ensures precise and reliable sensor operation for critical machinery monitoring applications.Its robust design guarantees accurate vibration and position measurement data.

Application Scenarios:

In a large gas turbine power plant,monitoring the radial vibration of the turbine shaft is critical for predicting bearing wear and preventing catastrophic failure.The eddy current proximity probes installed near the bearings provide this vital data,but they require an exceptionally clean and stable power source to function accurately.The BENTLY 2300/25-00power supply is mounted in a control panel nearby,providing the required-24 VDC to the probes.Its high-quality regulation ensures that electrical noise from the plant’s high-power equipment does not interfere with the microvolt-level signals from the probes.This allows the monitoring system to detect even minute changes in vibration,enabling the maintenance team to schedule a bearing replacement during a planned outage instead of experiencing a forced outage that could cost over$1 million per day in lost generation.The 2300/25-00is the unsung hero that makes this predictive maintenance strategy possible.

Parameter:

Main Parameters

Value/Description

Product Model

2300/25-00

Manufacturer

Bently Nevada(Baker Hughes)

Product Type

Proximitor Power Supply

Input Voltage

90-132 VAC/180-264 VAC,47-63 Hz(Selectable)

Output Voltage

-24 VDC(±0.1%)Regulated

Output Current

Up to 200 mA

Ripple&Noise

<2 mV RMS(Critical for signal clarity)

Load Regulation

±0.05%

Line Regulation

±0.05%

Operating Temperature

-20°C to+65°C

Safety Certifications

cULus,CE marked

Compatibility

Bently Nevada 2300 series proximity transducers

Technical Principles and Innovative Values:

The BENTLY 2300/25-00is far more than a simple DC power supply;it is a precision instrument engineered specifically for the demanding requirements of eddy current sensing technology.

Innovation Point 1:Ultra-Low Noise Power Delivery.The core value of the 2300/25-00lies in its exceptionally clean output.Eddy current proximity probes measure minute changes in the electromagnetic field,and their output signals are very small.Any noise or ripple on the-24 VDC excitation voltage directly superimposes onto the measurement signal,creating inaccurate readings.The 2300/25-00’s advanced regulation circuitry and filtering ensure ripple is kept below 2 mV RMS,which is crucial for obtaining valid dynamic vibration waveforms and precise DC gap voltage measurements.This allows condition monitoring systems to accurately detect early-stage machine faults like shaft cracks or rubs.

Innovation Point 2:Robust Industrial Design for Mission-Critical Reliability.Unlike standard laboratory power supplies,the 2300/25-00is built to withstand the electrical and environmental harshness of an industrial plant.It features wide-range input voltage acceptance with selectable 115V/230V operation,allowing it to handle voltage sags and surges without affecting the output.Its operating temperature range and component selection are tailored for long-term,24/7 operation in control panel environments,ensuring continuous protection for valuable assets like turbines and compressors.

Innovation Point 3:Simplified Integration and Diagnostics.The module is designed for easy installation in standard racks and features clear status indicators.This simplicity reduces installation time and potential for error.Its reliability means that when a machinery monitoring system exhibits problems,the power supply is rarely the culprit,allowing maintenance personnel to focus troubleshooting on the sensors and cabling,thereby reducing mean time to repair(MTTR).

Application Cases and Industry Value:

Case 1:Refinery Centrifugal Compressor Train Protection.In a large refinery,a hydrogen recycle compressor driven by a steam turbine is critical to the process.The compressor train is equipped with multiple Bently Nevadaproximity probes on both the turbine and compressor bearings to monitor radial vibration and axial position.These probes are all powered by several 2300/25-00power supply modules in a centralized cabinet.The stability of these power supplies ensured that during a sudden process upset,the monitoring system provided clean,reliable data that confirmed the compressor was approaching its surge line.The control system successfully enacted anti-surge measures based on this data,preventing damage that could have led to a three-week outage and millions in lost production and repair costs.

Case 2:Paper Machine Roll Vibration Analysis.A paper mill was experiencing unexplained quality issues with its finished product.The maintenance team used a portable data collector to analyze vibration on the large rolling drums,which relied on permanently installed proximity probes.Initially,the data was noisy and inconclusive.They traced the issue to an aging,generic power supply used for the probes.Replacing it with a genuine BENTLY 2300/25-00immediately resulted in clear vibration spectra,which revealed a misalignment issue at a specific gear mesh frequency.Correcting the misalignment resolved the quality problem,saving thousands of dollars in raw material waste and customer rejections.

Related Product Combination Solutions:

The BENTLY 2300/25-00is a key component in a proximity measurement system.It is typically used with:

BENTLY 3300 XL 5mm Proximitor(e.g.,330101-00-05-10-02-00):The sensor and built-in oscillator that requires the clean power from the 2300/25-00.

BENTLY 3300/464-Channel Proximitor Power Supply:A higher-density alternative for systems with many probes.

BENTLY 3500/42MProximitor Monitor:The monitoring module that interprets the signal from the proximitor.

BENTLY 130838-01Coaxial Cable:The low-capacitance cable that connects the probe to the system.

BENTLY 216T1201-01Extension Cable:For long-distance runs between the sensor and the monitoring frame.

Installation,Maintenance,and Full-Cycle Support:

Installation of the BENTLY 2300/25-00is straightforward but requires attention to detail.The module is designed for mounting on a standard DIN rail within a control cabinet.The first step is to ensure the input voltage selector switch is set correctly for the local mains supply(115V or 230V)before applying power.The input power should be connected via a suitably rated circuit breaker.The-24 VDC output is then distributed to the individual proximity transducers(proximitors).It is critical to use proper grounding practices and to keep the DC output wiring separate from AC power lines to prevent noise induction.

Maintenance is minimal due to the unit’s high reliability.The primary task is periodic visual inspection to ensure the unit’s status indicator is green and that there are no signs of overheating or damage.For critical machinery,it is prudent to measure the output voltage annually to verify it remains within the specified tolerance of-24 VDC±0.1%.A drift outside this tolerance could indicate a failing component and warrants preemptive replacement.We supply genuine,factory-fresh BENTLY 2300/25-00power supplies.Each unit is tested to ensure it meets all original performance specifications,particularly the critical low-ripple output.We provide a 12-month warranty and technical support to assist with integration into your machinery protection system.

Ensure the integrity of your machinery protection data.Contact us for genuine Bently Nevada components and expert technical support.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: