Product Overview

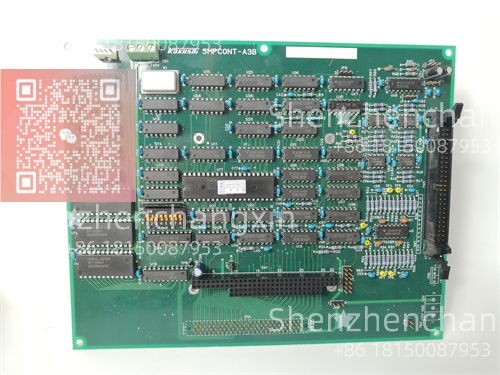

KOKUSAI SMPCONT-A3Bis a high-precision process controller specifically designed for semiconductor manufacturing equipment,providing advanced control capabilities for wafer processing applications.This sophisticated control module forms the core of Kokusai’s semiconductor fabrication systems,delivering precise process parameter regulation and equipment control for diffusion furnaces,CVD systems,and other thermal processing equipment.Engineered to meet the stringent requirements of semiconductor manufacturing,the SMPCONT-A3Bensures exceptional process repeatability and equipment stability in cleanroom environments where nanometer-scale precision is critical for production yield.

The controller features a multi-zone temperature control system capable of maintaining precise thermal profiles across large processing chambers.KOKUSAI SMPCONT-A3Bincorporates advanced gas flow control algorithms that regulate precursor delivery with high accuracy,ensuring consistent film deposition characteristics.Its robust industrial design withstands the challenging environment of semiconductor fabs,while the comprehensive diagnostic system monitors process conditions and equipment health in real-time.The module’s high-speed communication interfaces enable seamless integration with factory automation systems and support advanced process control strategies.

Technical Specifications

Parameter Name

Parameter Value

Product Model

SMPCONT-A3B

Manufacturer

Kokusai Electric

Product Type

Semiconductor Process Controller

Control Zones

Up to 8 zones

Temperature Range

200°C to 1200°C

Temperature Control Accuracy

±0.1°C

Gas Flow Channels

16 channels

Flow Control Accuracy

±1%of setpoint

Communication Interface

Ethernet,RS-485,DeviceNet

Processor

32-bit RISC

Memory

512MB DDR3

Storage

2GB Flash

Operating Temperature

+5°C to+40°C

Storage Temperature

-20°C to+60°C

Power Supply

100-240VAC

Power Consumption

150W maximum

Certifications

SEMI,CE

Main Features and Advantages

KOKUSAI SMPCONT-A3Butilizes advanced PID control algorithms with auto-tuning capability that optimizes control parameters for different process recipes.The controller’s multi-zone temperature management system ensures uniform thermal distribution across large wafer batches,critical for achieving consistent film properties.Advanced gas delivery control maintains precise flow rates and mixture ratios,while the recipe management system supports hundreds of process recipes with seamless transitions.

The controller features comprehensive safety interlocks and purge control functions that ensure safe equipment operation during process transitions.SMPCONT-A3B’s high-resolution data logging capability records all process parameters for traceability and analysis,while the remote monitoring function allows engineers to oversee process conditions from outside the cleanroom.The module’s modular design facilitates easy maintenance and component replacement,minimizing equipment downtime.

Advanced multi-zone temperature control

Precise gas flow regulation

Comprehensive recipe management

High-resolution process data logging

Remote monitoring capabilities

Application Field

KOKUSAI SMPCONT-A3Bis primarily used in semiconductor wafer fabrication:

Diffusion furnace process control

Chemical vapor deposition systems

Thermal oxidation processes

Annealing and doping systems

Related Products

SMPCONT-A4B:Enhanced version with more control zones

SMPCONT-B3B:Basic version for simpler applications

SMPGAS-A3B:Gas panel controller

SMPTEMP-A3B:Temperature control module

Installation and Maintenance

Installation requires cleanroom conditions and proper grounding.Regular calibration of sensors and actuators is essential.

Product Guarantee

We guarantee genuine Kokusai components with complete documentation and technical support.

We guarantee genuine KOKUSAI products with complete certification.Contact us for technical support and competitive pricing.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: