Product Overview

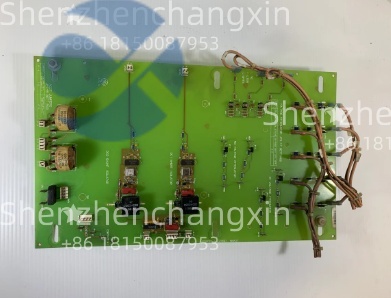

The GE DS200SIOBH1ABArepresents General Electric’s engineering excellence in industrial control systems,designed as a sophisticated digital input/output control board for the Mark V turbine control platform.This advanced component serves as a critical interface module in industrial automation architectures,providing reliable signal processing and communication capabilities for demanding power generation environments.The module forms an integral part of GE’s comprehensive control ecosystem,delivering robust performance where precision signal handling and system reliability are paramount requirements for operational continuity and equipment protection in challenging industrial applications.

As a specialized digital I/O solution,the GE DS200SIOBH1ABAexcels in managing multiple signal channels with advanced configuration options,featuring 20 jumper switches and 3 switch blocks totaling 18 individual switches for precise system customization.The board incorporates sophisticated interface technology that enables it to handle complex signal processing requirements with exceptional accuracy and reliability,supporting both digital inputs and outputs through its comprehensive 40-pin connector system.Its design emphasizes seamless integration within the Mark V control architecture while providing the processing capacity necessary for sophisticated control strategies and system monitoring functions essential for turbine protection and optimization.

The implementation of the GE DS200SIOBH1ABAenhances overall system intelligence and control precision in applications ranging from simple signal conditioning to complex turbine management systems.The module’s robust construction and industrial-grade components ensure dependable operation even in challenging environmental conditions characterized by temperature variations,electrical noise,and mechanical stress.With its comprehensive feature set and reliable performance characteristics,the GE DS200SIOBH1ABAdelivers significant value in applications requiring precise signal management,accurate monitoring,and uninterrupted operation of critical industrial equipment and processes.

Technical Specifications

Parameter Name

Parameter Value

Product Model

DS200SIOBH1ABA

Manufacturer

General Electric(GE)

Product Type

Digital I/O Control Board

Compatible System

Mark V Series

Operating Voltage

12V DC

Maximum Current

500mA

Communication Interface

RS-485

Digital I/O Channels

32 inputs/32 outputs

Jumper Settings

20 configurable jumpers

Switch Blocks

3 blocks with 6 switches each

Connector Type

40-pin

Dimensions

120mm×60mm×15mm

Weight

0.2kg

Operating Temperature

-20°C to+70°C

Main Features and Advantages

Advanced configuration flexibility:The GE DS200SIOBH1ABAincorporates sophisticated configuration options through its extensive jumper and switch system,featuring 20 programmable jumpers and 3 switch blocks containing 6 switches each for precise operational customization.This comprehensive configuration capability enables system integrators to tailor the module’s performance to specific application requirements,ensuring optimal signal processing and control functionality across diverse industrial scenarios.The preset factory default jumper configurations provide reliable baseline operation while allowing experienced technicians to fine-tune performance parameters for specialized applications,making the DS200SIOBH1ABAparticularly valuable for complex control environments where precise signal handling is essential for system efficiency and equipment protection.

Robust communication capabilities:A standout feature of the GE DS200SIOBH1ABAis its reliable communication interface utilizing RS-485 protocol,which ensures stable data exchange within the Mark V control system architecture.The module’s 40-pin connector system provides secure integration with various control system components,facilitating efficient signal transmission between field devices and central processors.This communication reliability makes the DS200SIOBH1ABAparticularly valuable in distributed control environments where coordinated system operation and centralized monitoring are essential for operational efficiency and equipment protection.The integrated LED status indicator provides real-time operational feedback,enabling quick visual confirmation of module functionality and simplifying troubleshooting procedures during system operation.

Durable industrial construction:Engineered for reliability in demanding industrial environments,the GE DS200SIOBH1ABAfeatures a robust construction that withstands the challenging conditions typical of power generation and industrial applications.The module operates effectively across a temperature range from-20°C to+70°C and incorporates protection mechanisms against electrical anomalies and environmental stressors.Its compact dimensions(120mm×60mm×15mm)and lightweight design(0.2kg)facilitate straightforward integration into control cabinets while maintaining proper ventilation and service accessibility.The module’s design includes comprehensive protection features that ensure stable operation even in conditions characterized by electrical noise,vibration,and temperature fluctuations common in industrial facilities.

Comprehensive digital signal handling:The GE DS200SIOBH1ABAoffers extensive digital signal processing capabilities through its support for 32 digital inputs and 32 digital outputs,providing versatile connectivity options for various industrial sensors and actuators.This high-density I/O configuration enables the module to handle multiple control points simultaneously,reducing the need for additional expansion modules and simplifying system architecture.The board’s design ensures accurate signal processing with minimal latency,maintaining signal integrity even in electrically noisy environments.This reliable signal handling capability makes the DS200SIOBH1ABAparticularly valuable for applications requiring precise digital signal management and responsive control in critical automation systems where signal accuracy directly impacts operational safety and efficiency.

Application Field

The GE DS200SIOBH1ABAfinds extensive application in power generation facilities,where it serves as a critical component in turbine control systems for both gas and steam turbine applications.The module provides essential digital I/O functionality for the Mark V control system,managing critical control functions including valve positioning,safety interlocks,and equipment sequencing operations.The DS200SIOBH1ABAis particularly valuable in combined cycle power plants where coordinated control between multiple turbines optimizes overall plant efficiency while ensuring reliable power delivery to the grid.Its robust design and reliable performance make it well-suited for the continuous operation requirements of base load power generation applications where control system integrity is essential for protective relaying and equipment protection.

In industrial manufacturing environments,the GE DS200SIOBH1ABAcontributes to process automation and equipment protection through its advanced digital signal processing capabilities.The module manages critical control functions in complex manufacturing processes,including equipment sequencing,safety interlocking,and status monitoring operations.Industries such as automotive manufacturing,chemical processing,and material handling utilize the DS200SIOBH1ABAfor its ability to maintain precise control over discrete parameters while providing comprehensive system monitoring and diagnostic information.The module’s communication capabilities facilitate integration with plant distributed control systems,enabling centralized monitoring and control of manufacturing operations while ensuring reliable performance through accurate signal processing and condition monitoring.

The oil and gas industry leverages the GE DS200SIOBH1ABAfor critical control applications in upstream,midstream,and downstream operations.In upstream applications,the module provides digital I/O functions for compressor stations and pumping facilities,ensuring reliable operation of equipment essential for hydrocarbon transportation.Midstream operations utilize the module for pipeline monitoring and control,while downstream refining operations benefit from its precise digital control capabilities in process units where equipment sequencing and safety interlocking are critical for operational safety.The module’s rugged design and reliable performance make it suitable for the challenging environments encountered in oil and gas applications,maintaining stable operation even in remote or harsh operating conditions.

Infrastructure applications represent another significant area where the GE DS200SIOBH1ABAdelivers value through reliable control system performance.Water treatment plants utilize the module for process control in purification systems,pumping stations,and distribution networks,ensuring consistent operation through reliable digital signal handling.Transportation infrastructure,including tunnel ventilation systems and bridge control mechanisms,benefits from the module’s reliable operation and comprehensive monitoring capabilities.In these critical infrastructure applications,the DS200SIOBH1ABAcontributes to public safety and service reliability through its consistent performance and robust design philosophy,ensuring uninterrupted operation of essential services through reliable digital signal management and control system integration.

Related Products

DS200TCQAG1BFE:Analog I/O module for complementary signal processing in Mark V systems

IS200TRLYH1C:Relay output module for expanded control capabilities in related systems

IC693ALG221:Analog input module for signal processing applications

DS200DCFBG1BGB:I/O module for distributed control system expansion

IS215ACLEH1B:Application control layer module for enhanced system integration

BENTLY 3500/15:Vibration monitoring system for complementary machinery protection

GE IC695ALG600:Analog input module for expanded signal handling capabilities

Installation and Maintenance

Pre-installation preparation:Before installing the GE DS200SIOBH1ABA,verify that the installation environment complies with specified temperature,humidity,and cleanliness requirements.Ensure adequate clearances around the module for proper ventilation and heat dissipation,and confirm that the mounting surface can support the module’s weight.Check incoming power specifications to ensure compatibility with the module’s voltage input range(12V DC),and verify that all necessary mounting hardware and connectors are available.For the DS200SIOBH1ABA,particular attention should be paid to jumper configuration settings,ensuring they match the specific application requirements.The module features 20 configurable jumpers and 3 switch blocks with 6 switches each that require proper setting according to the operational parameters needed for the specific control application

.

Maintenance recommendations:Implement regular inspection cycles for the GE DS200SIOBH1ABA,focusing on connection integrity,environmental conditions,and operational performance.Quarterly visual inspections should check for signs of component degradation,loose connections,or abnormal heating at the 40-pin connector points.Semiannual performance verification should include signal continuity tests and communication checks to ensure the module operates within specified parameters.Maintain clean operating conditions to prevent dust accumulation that could impair cooling efficiency,and ensure adequate ventilation around the module at all times.For the DS200SIOBH1ABA,maintain accurate records of jumper settings and switch configurations,as these critical parameters determine the module’s operational characteristics.Regularly review system logs and performance data to identify trends that might indicate developing issues,and perform comprehensive system backups before implementing any configuration changes to ensure system integrity and quick recovery capability if needed.The module’s LED indicator should be monitored during routine checks to verify proper operational status,and any abnormal indications should be investigated promptly to prevent potential system issues

.

Product Guarantee

We guarantee that all GE DS200SIOBH1ABAmodules supplied are genuine General Electric components,manufactured to original specifications and subjected to rigorous quality verification processes.Our commitment to quality includes comprehensive testing of each module’s digital I/O functions,communication capabilities,and environmental resilience to ensure reliable operation in industrial conditions.We provide technical support from engineers familiar with GE Mark V systems to assist with configuration challenges and application optimization.For the DS200SIOBH1ABA,we offer standard warranty coverage with options for extended protection plans,supported by our global logistics network that ensures timely delivery and ongoing supply continuity for this critical control component.Our quality assurance process includes verification of all input and output channels,signal processing accuracy,and communication capabilities,ensuring that each module meets original performance specifications before shipment,providing customers with confidence in the product’s reliability and longevity in demanding industrial applications where signal integrity is critical for system operation and equipment protection.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: