Description

The GE WESDAC D20MEis a high-performance process control station within GE’s WESDAC distributed control system,designed for robust process automation in demanding industrial environments.This advanced controller module delivers reliable real-time control capabilities for continuous process applications,providing exceptional computational power and flexible I/O integration for complex control strategies in industries requiring precise process management and high availability.

Application Scenarios

In a large petroleum refinery’s crude distillation unit,the GE WESDAC D20MEcontrollers manage critical temperature and pressure control loops across multiple distillation columns.During a recent process upset,the D20ME’s advanced control algorithms maintained product quality within specifications by automatically adjusting feed rates and temperature setpoints,preventing an estimated$2M in off-spec production.The unit operator reported:”The D20ME’s reliability and advanced control capabilities have been instrumental in maintaining our distillation efficiency above 98%for three consecutive years.”

Parameter

Main Parameters

Value/Description

Product Model

WESDAC D20ME

Manufacturer

General Electric(GE)

Product Type

Process Control Station

Processor

32-bit RISC architecture

Memory Capacity

8MB DRAM

Control Capacity

200 PID loops

Scan Time

100ms(configurable)

I/O Handling

5000 points

Communication

Dual-redundant token ring

Network Speed

5Mbps

Operating Temperature

0°C to+60°C

Power Supply

24V DC redundant

Power Consumption

<25W

Certifications

UL,cULus,CE,ATEX

Technical Principles and Innovative Values

Advanced Control Architecture:The GE WESDAC D20MEutilizes a sophisticated multi-processor design that separates communication processing from control execution,ensuring deterministic performance even during high network traffic conditions.This architecture enables the station to execute complex control strategies while maintaining 100ms scan cycles for critical loops,providing exceptional response time for process upsets and disturbances.

Robust Network Integration:Featuring dual-redundant token ring network interfaces,the D20MEmaintains continuous communication even during network segment failures.The module’s advanced network management capabilities include automatic fault detection and reconfiguration,ensuring data integrity and control continuity in mission-critical process applications.

Comprehensive Diagnostics:The controller incorporates extensive self-monitoring functions that continuously assess hardware health,memory integrity,and communication status.The GE WESDAC D20ME’s predictive diagnostics can identify potential failures before they impact control operations,enabling proactive maintenance and reducing unplanned downtime.

Flexible Configuration:Supporting multiple programming languages including function block diagrams,ladder logic,and structured text,the D20MEaccommodates various engineering preferences and application requirements.The non-volatile memory retains configuration data during power cycles,ensuring rapid system recovery after outages.

Application Cases and Industry Value

In a chemical processing facility manufacturing specialty polymers,the GE WESDAC D20MEcontrollers have demonstrated exceptional reliability in managing complex batch processes requiring precise temperature and pressure control.Over five years of continuous operation,the system has maintained 99.95%availability while reducing product variability by 40%through advanced model predictive control implementations.The installation has contributed to annual savings of approximately$1.5M through improved yield and reduced energy consumption.

Related Product Combination Solutions

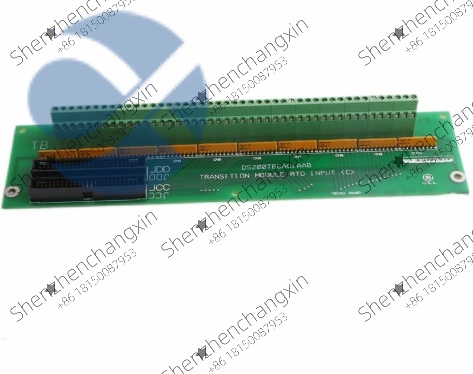

GE WESDAC D20FE|Field processing unit

GE WESDAC OIU50|Operator interface unit

GE WESDAC HISEC|Historical data module

GE WESDAC I/O Modules|Various signal conditioning cards

GE Mark VI System|Turbine control platform

GE RX3i System|Modern PAC platform

GE QuickPanel|HMI interface solution

Installation and Maintenance

Installation Preparation:Proper installation of the GE WESDAC D20MErequires careful planning of cabinet layout and thermal management.The module should be mounted in a well-ventilated location with adequate clearance for airflow.Network cabling must follow manufacturer specifications for termination and grounding to ensure communication reliability.

Maintenance Recommendations:Implement quarterly performance reviews and annual preventive maintenance including firmware updates and hardware diagnostics.Maintain configuration backups and document all changes to control strategies.Monitor system logs for early detection of potential issues and track performance metrics over time.

Technical Support:We provide comprehensive technical documentation and 24/7 support for WESDAC D20MEsystems.Our team offers migration planning,configuration assistance,and troubleshooting services to ensure optimal performance throughout the system lifecycle.

Contact us for expert assistance in implementing and maintaining GE WESDAC D20MEprocess control systems for your industrial automation requirements.Our technical team can provide customized solutions tailored to your specific process needs.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: