Description

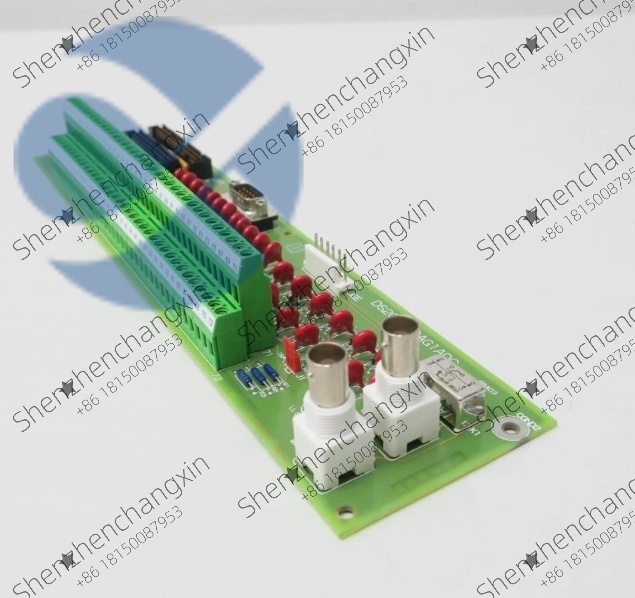

The GE DS200RTBAG2AFB is a relay output terminal board designed for the GE Mark V Speedtronic™turbine control system,widely used in gas and steam turbine applications for power generation and industrial drive service.This module provides 16 high-reliability electromechanical relay outputs that translate digital commands from the Mark V controller into dry contact closures capable of directly switching field devices such as:

Emergency fuel shutoff solenoids

Lube oil pump motor starters

Cooling fan contactors

Alarm horns and beacon lights

Auxiliary generator breakers

Each relay features Form C(SPDT)contacts rated for 5A at 250V AC or 30V DC,enabling universal compatibility with both AC and DC loads.The board mounts vertically in the Mark V I/O rack and connects via a high-density backplane connector to the controller’s digital output drivers(e.g.,from a DTBA board).All relays are optically isolated from logic circuits and include LED status indicators for real-time visual diagnostics.

Designed for mission-critical environments,the DS200RTBAG2AFB includes conformal coating to resist moisture,salt,and airborne contaminants—common in coastal or refinery settings.

Application Scenario

At a cogeneration facility in California,a Mark V-controlled steam turbine tripped unexpectedly due to a failed lube oil pump not starting during coast-down.Investigation revealed welded contacts on an aging third-party relay module that replaced the original GE unit years prior.The plant reinstalled a genuine GE DS200RTBAG2AFB,which restored reliable pump control.During the next scheduled outage,thermal imaging confirmed clean switching with no contact arcing.Over the following 18 months,the system logged zero relay-related faults,ensuring compliance with NERC PRC-005 maintenance standards and avoiding potential penalties.

Parameter

Main Parameters Value/Description

Model DS200RTBAG2AFB

Manufacturer General Electric(GE Power/GE Vernova)

Product Type Relay Terminal Output Board(RTBA)

Compatible Systems GE Mark V Speedtronic™(Simplex,Dual,TMR)

Number of Relays 16 independent channels

Contact Type Form C(SPDT–Single Pole Double Throw)

Contact Rating 5A 250V AC,5A 30V DC(resistive load)

Coil Voltage 24V DC(driven by Mark V DTBA output)

Isolation Optical isolation between logic and field sides

Indicators Red/green LEDs per channel(energized/de-energized state)

Mounting Vertical slot in Mark V I/O rack(backplane-connected)

Operating Temperature 0°C to+60°C

Protection Conformal coated(IPC-CC-830 compliant)

Certifications UL 508,CE,RoHS

Technical Principles and Innovative Values

Innovation Point 1:Direct Field Device Interfacing Without Interposing Relays

The 5A rating eliminates the need for external interposing relays in most applications—reducing panel space,cost,and failure points.

Innovation Point 2:Visual Diagnostics Enable Rapid Troubleshooting

Technicians can instantly verify command execution by checking LED status—no multimeter or HMI access required during emergencies.

Innovation Point 3:TMR System Compatibility

In redundant Mark V configurations,multiple DS200RTBAG2AFB boards can be wired in voted or parallel architectures for critical trip functions.

Innovation Point 4:Long Mechanical Life in High-Cycle Applications

Relays rated for>500,000 operations ensure longevity even in frequently cycled auxiliary systems(e.g.,cooling fans).

Application Cases and Industry Value

A petrochemical plant in Texas upgraded its emergency vent system by replacing pneumatic timers with a Mark V-controlled sequence using DS200RTBAG2AFB relays to actuate isolation valves and flare igniters.The solid-state-to-relay interface provided fail-safe timing with full audit trail via HMI.The project achieved SIL 2 compliance under IEC 61511 and reduced proof-test time by 50%—delivering a ROI in under 14 months.

Related Product Combination Solutions

GE Mark V Core&I/O Racks:Host platform for DS200RTBAG2AFB

GE DS200DTBAG1A/DS200DTBAG2A:Digital output driver boards that energize RTBA relays

GE Toolbox™Software:For monitoring output commands and logging events

ASCO 8210G94/Burkert 6013:Common solenoid valves driven by RTBA contacts

GE IS200TRGLH1A:Turbine trip manifold interface(often downstream of RTBA)

Phoenix Contact REL-MR-24DC/21HC:Alternative relay if replacement needed outside Mark V

GE Manual GEH-6190:Mark V Hardware Reference–includes RTBA wiring diagrams

Fluke 771 Milliamp Process Clamp Meter:Useful for validating upstream DTBA signals

Installation,Maintenance,and Full-Cycle Support

The GE DS200RTBAG2AFB installs into a designated slot in the Mark V I/O chassis.Field wiring connects to removable screw terminals on the front(max 14 AWG).No configuration is required—the board operates passively based on controller output signals.

Best practices:

Torque terminals to 0.6 Nm to prevent loosening from vibration

Use shielded cable for long runs to reduce EMI-induced chatter

Label each relay function on the terminal cover for clarity

Maintenance includes:

Annual inspection for contact pitting or carbon buildup

Functional test:simulate command→verify contact closure with continuity check

Cleaning dust from LED windows and relay vents

We supply every DS200RTBAG2AFB with:

Relay cycle test report(10,000 operations at rated load)

Contact resistance<50 mΩverification

Conformal coating integrity check

12-month warranty

Our technical team provides support for integration into TMR logic,load compatibility analysis,and migration planning to Mark VIe.

Contact us for a genuine,tested GE DS200RTBAG2AFB—whether you’re repairing a failed output,modernizing auxiliary controls,or building strategic spares for your Mark V turbine.With reliable,visible,and robust relay switching from the DS200RTBAG2AFB,your safety and support systems stay ready—every second,every start,every trip.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: