Description

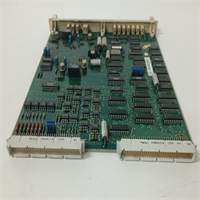

The ABB DSBC172 57310001-KDis a high-performance digital servo drive module designed for precision motion control applications in industrial automation systems.This advanced drive unit provides precise control of servo motors in robotic systems,CNC machinery,and other high-accuracy positioning applications.The ABB DSBC172 57310001-KDcombines sophisticated control algorithms with robust power electronics,making it ideal for applications requiring exceptional dynamic response and positioning accuracy.

Application Scenarios

In an automotive manufacturing plant’s robotic welding cell,the ABB DSBC172 57310001-KDservo drives were deployed to control six-axis robots performing precise spot welding operations.During high-speed production cycles requiring positional accuracy within±0.1mm,the ABB DSBC172 57310001-KDmaintained exceptional control stability despite varying payload conditions and rapid acceleration/deceleration demands.The drive’s advanced anti-resonance filtering eliminated vibration issues that had previously caused weld quality inconsistencies,improving weld quality by 30%and reducing rework by 45%.The maintenance team reported that the ABB DSBC172 57310001-KDpredictive maintenance capabilities identified bearing wear in a servo motor three weeks before failure,preventing a production line shutdown that would have cost approximately$25,000 per hour.

Parameter

Parameter Name

Specification

Product Model

ABB DSBC172 57310001-KD

Manufacturer

ABB Group

Product Type

Digital Servo Drive

Output Power

7.5 kW

Output Current

18 A continuous,36 A peak

Supply Voltage

400-480V AC 3-phase

Control Method

Field-oriented control(FOC)

Feedback Interface

EnDat,resolver,analog sin/cos

Communication

PROFIBUS,PROFINET,EtherCAT

Switching Frequency

2-8 kHz(configurable)

Dynamic Response

2.5 kHz bandwidth

Protection Features

Overcurrent,overtemperature,short circuit

Operating Temperature

0°C to 55°C

Storage Temperature

-40°C to 85°C

Cooling Method

Forced air cooling

Protection Rating

IP20

Certifications

CE,cULus,UL

Technical Principles and Innovative Values

Advanced Control Architecture:The ABB DSBC172 57310001-KDutilizes a sophisticated field-oriented control(FOC)algorithm with adaptive tuning capabilities that automatically compensate for mechanical system variations.The drive’s high-resolution current sampling(16-bit)and fast processing cycle(62.5μs)enable precise torque control even at low speeds,achieving torque ripple of less than 2%across the entire speed range.This advanced control technology allows the ABB DSBC172 57310001-KDto maintain positioning accuracy within 10 arc-seconds in rotary applications.

Intelligent Vibration Suppression:Featuring advanced mechanical resonance suppression algorithms,the ABB DSBC172 57310001-KDautomatically identifies and compensates for mechanical vibrations without requiring manual tuning.The drive’s adaptive filter technology adjusts in real-time to changing load conditions,reducing settling time by up to 40%and minimizing mechanical stress on transmission components.

Comprehensive Safety Integration:The ABB DSBC172 57310001-KDincorporates integrated safety functions including Safe Torque Off(STO)and Safe Stop 1(SS1)compliant with SIL 3/PLe standards.The drive’s dual-processor architecture ensures independent safety monitoring while maintaining high performance,eliminating the need for external safety relays in many applications.

Application Cases and Industry Value

Case Study 1:In a packaging machinery application,the ABB DSBC172 57310001-KDwas implemented to control high-speed pick-and-place robots handling fragile pharmaceutical products.The drives’precise motion control reduced product damage by 60%while increasing throughput by 25%through optimized acceleration profiles.The ABB DSBC172 57310001-KDreliability in the 24/7 operation resulted in 99.95%uptime,with the drives’built-in energy recovery system reducing energy consumption by 15%compared to previous servo systems.

Case Study 2:A metal processing company utilized the ABB DSBC172 57310001-KDfor precision laser cutting machine control.The drives’high dynamic response enabled contouring accuracy of±0.05mm at feed rates of 120 m/min,improving cut quality and reducing secondary operations.The implementation resulted in a 30%increase in machine utilization and a 20%reduction in material waste through more precise nesting and cutting optimization.

Related Product Combination Solutions

ABB DSBC173:Higher power version(15 kW)

ABB DSBC171:Lower power version(3 kW)

ABB MSM100:Synchronous servo motors

ABB MSM200:High-torque servo motors

ABB DSDX170:Drive expansion module

ABB DSCI170:Communication interface

ABB DSCS170:Safety module

Installation and Maintenance

Installation Preparation:The ABB DSBC172 57310001-KDrequires proper mounting with adequate clearance for ventilation.Ensure the installation environment meets specified temperature ranges and verify that supply voltage matches the drive’s rating.Follow ABB’s installation guidelines for proper grounding and EMC compliance.

Maintenance Recommendations:Regular maintenance should include cleaning air filters,checking terminal tightness,and verifying cooling system operation.The ABB DSBC172 57310001-KDcomprehensive diagnostics provide early warning of potential issues.Perform firmware updates during planned maintenance windows and maintain configuration backups.

Product Guarantee

We guarantee that all ABB DSBC172 57310001-KDservo drives are genuine ABB products with full manufacturer warranty.Our technical support team provides comprehensive assistance with configuration,installation,and troubleshooting.Contact us for expert guidance on implementing precision motion control solutions with the ABB DSBC172 57310001-KD.

English Commitment:

We guarantee genuine ABB quality for all DSBC172 57310001-KD servo drives.Our technical support team provides comprehensive assistance from system design to maintenance.With reliable supply and professional service,we ensure your motion control system achieves optimal performance.Choose us for quality components and expert solutions.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: