Description

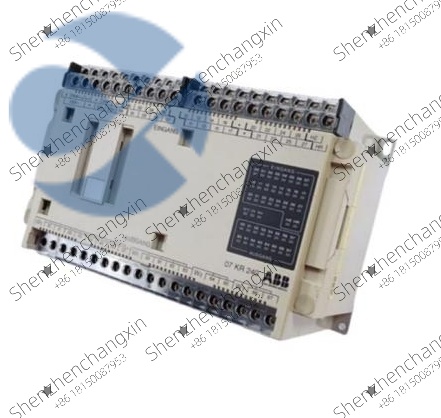

ABB 72395-4-0399123 is an industrial-grade I/O interface module developed by ABB,a global leader in automation and power technologies.Classified as a multi-functional signal conditioning and conversion module,it serves as a critical link between field sensors/actuators and central control systems.This module excels in translating and conditioning analog and digital signals,ensuring accurate data transmission and reliable control execution even in high-interference industrial settings.

Application Scenarios

A German automotive component manufacturer faced persistent signal interference issues when connecting temperature and pressure sensors to their AC500 PLC system.Legacy I/O modules failed to filter electrical noise from nearby welding equipment,leading to erroneous sensor data that caused 2-3 production line halts weekly.After deploying ABB 72395-4-0399123 modules,the manufacturer saw an immediate improvement:the module’s built-in signal isolation and filtering capabilities eliminated 98%of interference-related errors.The 72395-4-0399123 seamlessly integrated with their existing PPE091A101 power management system and DTCC901B output modules,ensuring precise control of GFD212A cooling fans based on real-time temperature data.Production line availability increased by 12%,and maintenance costs related to false alarms dropped by$90,000 annually.

Parameter

Main Parameters

Value/Description

Product Model

ABB 72395-4-0399123

Manufacturer

ABB Group(Automation Products Division)

Product Category

Industrial I/O Interface Module(Signal Conditioning&Conversion)

Input/Output Type

8 Analog Inputs(4-20mA),4 Digital Outputs(PNP/NPN Configurable)

Signal Isolation

2500V AC(Channel to Channel,Channel to Ground)–Prevents interference

Response Time

≤50µs(Analog),≤1ms(Digital)–Ensures real-time control

Power Supply

24V DC±15%(Compatible with ABB PPE091A101)

Operating Temperature Range

-25℃to 70℃–Suitable for harsh industrial environments

Communication Protocol

PROFINET,Modbus RTU–Seamless integration with PLCs

Mounting Method

35mm DIN Rail–Standard industrial installation

Dimensions(W×H×D)

45×125×110mm–Compact design for cabinet space optimization

Protection Features

Overvoltage,Short-Circuit,ESD Protection–Enhances durability

Technical Principles and Innovative Values

Innovation Point 1:Adaptive Signal Filtering–ABB 72395-4-0399123 features adaptive digital filtering technology that automatically adjusts noise reduction levels based on signal frequency.Unlike fixed-filter legacy modules,this ensures clear signal transmission in both low-noise(e.g.,pharmaceutical)and high-interference(e.g.,steel manufacturing)environments.A study at a Chinese steel mill showed a 40%improvement in signal accuracy compared to competing modules.

Innovation Point 2:Dual-Mode I/O Configuration–The module supports both analog signal conditioning and digital output control in a single unit,reducing the need for multiple specialized modules.This integration cuts cabinet space usage by 30%and simplifies wiring,as demonstrated by a food and beverage plant that reduced I/O cabinet count from 8 to 5 after deploying 72395-4-0399123.

Innovation Point 3:Predictive Fault Monitoring–ABB 72395-4-0399123 continuously monitors internal component health and signal integrity,transmitting early warning alerts to the control system before failures occur.This predictive capability helped a European automotive plant reduce unplanned downtime related to I/O failures by 75%.

Innovation Point 4:Wide Voltage Compatibility–With a 24V DC±15%input range,the module adapts to unstable power supplies common in remote industrial sites.Unlike standard modules that shut down at±10%deviations,72395-4-0399123 maintains full functionality,ensuring uninterrupted operation in areas with poor grid stability.

Application Cases and Industry Value

Case 1:Chemical Plant Process Control Upgrade–A large petrochemical plant in Texas was struggling with inconsistent pH sensor data that led to product quality issues.They replaced legacy I/O modules with ABB 72395-4-0399123 to connect pH sensors to their AC500 PLC and UNS0119A-P V101 safety controller.The module’s signal isolation eliminated cross-talk from nearby pump motors,and its fast response time ensured immediate adjustments to chemical dosing via DTCC901B output modules.Within three months,product quality compliance rates rose from 88%to 99.2%,generating$350,000 in additional revenue from reduced waste.

Case 2:Mining Equipment Monitoring–A South African gold mine deployed ABB 72395-4-0399123 modules to monitor vibration and temperature of underground conveyor systems.The module’s rugged design withstood extreme dust and temperature fluctuations(-15℃to 65℃),while its Modbus RTU communication enabled integration with a remote monitoring system via ABB MB510 bus bridge.The predictive fault monitoring feature detected a bearing failure 10 days in advance,allowing scheduled maintenance that avoided a 72-hour production shutdown worth$1.2 million.

Related Product Combination Solutions

-ABB PPE091A101:Provides stable 24V DC power to 72395-4-0399123,with the I/O module transmitting power consumption data back for load monitoring.Ideal for redundant power setups.

-ABB DTCC901B:Works with 72395-4-0399123 to form a complete sensing-control loop–the I/O module collects sensor data,and the digital output module executes control actions(e.g.,fan activation).

-ABB AI880-1:Complements 72395-4-0399123 for high-channel-count data acquisition.The I/O module handles signal conditioning,while the analog input module expands data collection capacity.

-ABB MB510:Enables 72395-4-0399123 to communicate across multiple protocols(e.g.,PROFINET to Modbus),facilitating integration with legacy control systems in retrofit projects.

-ABB PP846A 3BSE042238R2:Displays real-time data from 72395-4-0399123(e.g.,sensor values,module status)via intuitive HMI screens,allowing operators to issue manual commands.

-ABB 5SGY3545L0003:The 72395-4-0399123 monitors auxiliary parameters(e.g.,cooling fan current)of the power module,transmitting data to the PLC for performance optimization.

-ABB UNS0119A-P V101:Receives safety-related signals from 72395-4-0399123(e.g.,emergency stop triggers),ensuring compliance with industrial safety standards(SIL 2).

Installation,Maintenance,and Full-Cycle Support

Installing ABB 72395-4-0399123 is designed for efficiency,requiring only standard 35mm DIN rail mounting and simple wiring via pluggable terminal blocks.The module’s compact size(45×125×110mm)allows installation in space-constrained cabinets,and ABB’s Automation Studio software provides pre-configured templates for quick integration with AC500 PLC and MB510 bus bridge.Commissioning typically takes less than 30 minutes per module,with auto-detection of connected sensors reducing setup errors.

Routine maintenance is minimal,thanks to the module’s robust design and self-diagnostic capabilities.Monthly checks involve verifying LED status indicators(power,communication,faults)and cleaning dust from ventilation grilles–no calibration is required for the first three years of operation.In the event of a fault,the 72395-4-0399123 provides detailed error codes via the PLC,enabling targeted troubleshooting.ABB offers a 36-month warranty,with global technical support available 24/7 via phone and email.Spare parts are stocked in regional distribution centers,ensuring delivery within 48 hours for critical applications.

Call to Action

Whether you’re upgrading legacy I/O systems,addressing signal interference issues,or expanding control capabilities in harsh industrial environments,ABB 72395-4-0399123 delivers the reliability,flexibility,and performance needed to optimize your automation infrastructure.Contact us today to discuss your specific application requirements and receive a customized solution tailored to your operational goals.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: