Description

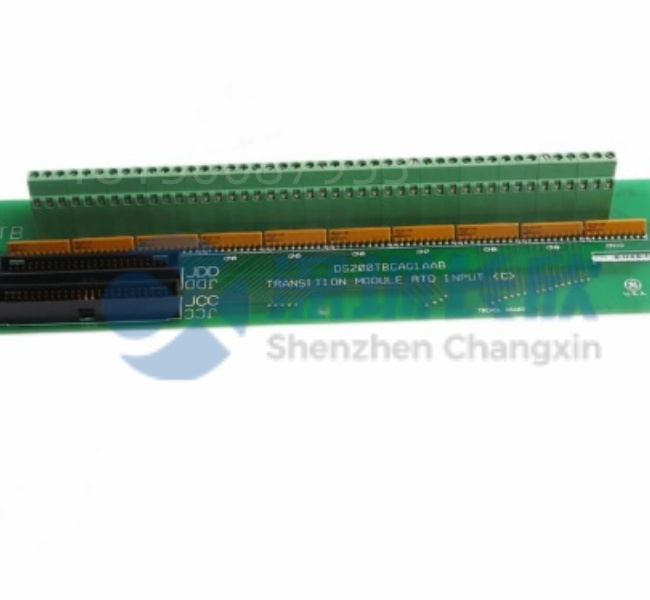

The General Electric DS200TBCAG1AAB is a terminal board (also known as a terminal base or carrier card) designed for use in GE Speedtronic™ Mark V distributed control systems (DCS), primarily deployed in gas and steam turbine power generation. It serves as the critical physical and electrical interface between plug-in I/O modules (such as DS200TBQBG, DS200TCCAG, or DS200RVPAG) and field wiring from sensors, actuators, and auxiliary equipment.

Mounted directly onto the Mark V I/O chassis backplane, the DS200TBCAG1AAB provides screw-terminal connections for field devices, built-in signal conditioning (e.g., filtering, fusing, or isolation where applicable), and robust mechanical support—ensuring reliable signal transmission in high-vibration, high-temperature environments typical of turbine enclosures.

Application Scenarios

At a combined-cycle power plant in the southeastern U.S., operators experienced intermittent false trips due to loose field connections on aging terminal blocks. Investigation revealed cracked terminal housings on legacy bases, causing intermittent contact resistance in thermocouple and pressure switch circuits. After replacing all affected units with new GE DS200TBCAG1AAB terminal boards, the plant eliminated connection-related faults. The secure screw terminals, gold-plated backplane contacts, and conformal coating ensured stable signal integrity—even during daily thermal cycling from 25°C to 65°C. Maintenance staff reported a 70% reduction in I/O troubleshooting time, proving that the DS200TBCAG1AAB is far more than just a “connector”—it’s a foundational element of system reliability.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Modular I/O Architecture Enabled by Standardized Terminal Bases

The DS200TBCAG1AAB allows any compatible I/O module to be hot-swapped without re-wiring field cables. This modularity drastically reduces maintenance downtime—technicians replace a failed card in minutes while field wiring remains untouched.

Innovation Point 2: Robust Mechanical & Electrical Design for Turbine Environments

Unlike generic terminal blocks, the DS200TBCAG1AAB features vibration-resistant screw terminals, gold-plated backplane contacts, and reinforced PCB laminate—ensuring decades of service in high-stress environments near rotating machinery.

Innovation Point 3: Signal Integrity Through Optimized Layout

Traces on the DS200TBCAG1AAB are impedance-controlled and shielded where necessary to minimize crosstalk between analog and digital signals—critical for accurate thermocouple or servo valve feedback.

Innovation Point 4: Lifecycle Support for Legacy Infrastructure

With thousands of Mark V systems still in operation worldwide, the DS200TBCAG1AAB plays a vital role in life-extension programs. Its continued availability prevents forced obsolescence and protects customer investment.

Application Cases and Industry Value

In a Middle Eastern peaker plant operating GE Frame 6B turbines, sand infiltration had corroded older terminal bases, causing erratic fuel valve position feedback. After installing new GE DS200TBCAG1AAB units with enhanced conformal coating, the plant achieved 24 months of uninterrupted operation—even during dust storms with PM10 levels exceeding 500 µg/m³. Engineers credited the sealed terminal design and corrosion-resistant plating for the improvement.

Similarly, a U.S. Navy ship using a Mark V-controlled LM2500 turbine relied on the DS200TBCAG1AAB’s MIL-spec ruggedness to maintain control signal integrity amid salt spray, shock, and EMI from radar systems—demonstrating its suitability beyond commercial power.

Related Product Combination Solutions

GE DS200TBQBG1A: Digital I/O module that plugs into DS200TBCAG1AAB for contact input/output

GE DS200TCCAG1A: Analog input card (thermocouple/RTD) used with DS200TBCAG1AAB

GE DS200RVPAG1A: Relay output module compatible with this terminal base

GE DS200CCTG1A: Mark V main controller—communicates with I/O via backplane through terminal bases

GE Mark V I/O Chassis (e.g., DS200PCCAG1): Houses multiple DS200TBCAG1AAB units

Phoenix Contact MSTB 2.5/..-ST: Generic terminal block—not recommended due to lack of Mark V integration

Honeywell CC-TB11: Terminal base for Honeywell RIO—functional analog but not cross-compatible

GE DS200TBXAG1A: Alternative terminal base for high-density applications

Installation, Maintenance, and Full-Cycle Support

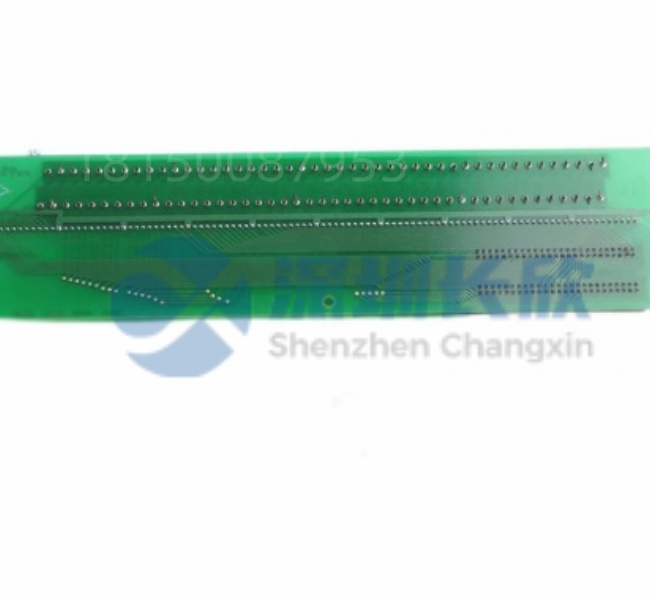

Installation of the DS200TBCAG1AAB is tool-free: align it with the guide rails in the Mark V I/O chassis and press until it locks into the backplane connector. Field wires are secured using captive screws—no ferrules required, though recommended for stranded wire. Always de-energize the cabinet before installation unless operating in a redundant configuration.

Maintenance involves periodic inspection of terminal tightness (torque: ~0.5 N·m), checking for corrosion or arcing, and verifying no bent pins on the backplane connector. The board itself has no active components—failure is almost always due to mechanical wear or environmental degradation.

We supply DS200TBCAG1AAB units that are:

100% functionally tested for continuity and insulation resistance

Inspected for PCB delamination, solder cracks, and terminal integrity

Cleaned and recoated with fresh conformal coating if refurbished

Shipped with terminal wiring diagrams and compatibility verification

Each unit includes a test certificate and 12-month warranty.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: