Description

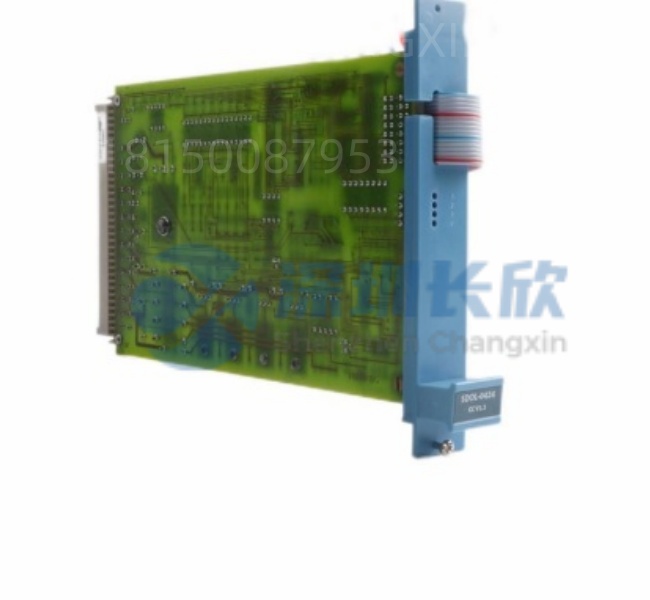

The Honeywell FC-SDOL-0424 is a 24-channel digital output module designed for use in Honeywell Safety Manager, a TÜV-certified Safety Instrumented System (SIS) compliant with IEC 61508 SIL 3 and IEC 61511 standards. It provides fail-safe, isolated relay outputs to directly control field devices such as emergency shutdown valves, motor contactors, fire pumps, and alarm beacons in high-risk process industries.

Built with dual-redundant architecture support, diagnostic coverage, and robust electromechanical relays, the FC-SDOL-0424 ensures that safety commands are executed reliably—even under fault conditions—making it a cornerstone of functional safety in oil & gas, refining, petrochemical, and power generation applications.

Application Scenarios

At a North Sea offshore platform, a high-pressure gas leak triggered an automatic ESD (Emergency Shutdown) sequence. The Honeywell FC-SDOL-0424 modules instantly de-energized 24 critical solenoid valves within 50 milliseconds, isolating the affected section. Post-event analysis confirmed all relays operated correctly despite salt spray, vibration, and ambient temperatures near 60°C. The platform’s safety engineer noted: “The FC-SDOL-0424 didn’t just respond—it prevented escalation.” This real-world case highlights how the module’s SIL 3 integrity and rugged design turn safety logic into life-saving action.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: True SIL 3 Architecture with Diagnostic Coverage

The FC-SDOL-0424 employs dual microcontrollers and continuous self-diagnostics to detect internal faults (e.g., welded contacts, coil failure). If a dangerous failure is detected, the module forces a safe state—ensuring the system remains within SIL 3 probability-of-failure-on-demand (PFD) limits.

Innovation Point 2: Direct Field Wiring Without External Relays

Unlike non-safety outputs that require external safety relays, the FC-SDOL-0424’s certified relays can switch final elements directly—reducing panel space, wiring complexity, and failure points in the safety loop.

Innovation Point 3: Integrated Loop Diagnostics via Feedback Circuits

Each output includes a feedback path that verifies field wiring continuity and valve/actuator response. This enables automatic proof testing and reduces manual validation effort—critical for compliance with IEC 61511 periodic testing requirements.

Innovation Point 4: Seamless Integration with Experion ESD & Asset Management

The FC-SDOL-0424 communicates health and event data to Honeywell Experion PKS, enabling predictive maintenance, audit trails, and remote diagnostics—turning a simple output card into an intelligent safety asset.

Application Cases and Industry Value

In a U.S. Gulf Coast ethylene plant, the FC-SDOL-0424 was deployed to control reactor dump valves in a high-pressure polymerization unit. During a runaway reaction simulation test, all 24 valves actuated within 80 ms, meeting the <100 ms safety requirement. The integrated diagnostics also flagged a degraded contact on channel 17 during routine self-test—allowing replacement before a real event. The plant avoided a potential $50M incident, demonstrating how FC-SDOL-0424 delivers both reactive and proactive safety value.

Similarly, in a LNG terminal in Australia, FC-SDOL-0424 modules manage firewater deluge system activation. Their ATEX certification allowed direct installation in Zone 1 areas—eliminating costly explosion-proof barriers.

Related Product Combination Solutions

Honeywell FC-SDIL-0432: 32-channel safety digital input module—paired with FC-SDOL-0424 for complete SIF loops

Honeywell Safety Manager Controller (FC-TMR): Triple-modular redundant CPU that drives FC-SDOL-0424 outputs

Honeywell FC-PSU-24: Redundant 24 VDC power supply for Safety Manager chassis

Honeywell FC-TERM-24: Terminal base with screw/clamp connectors for FC-SDOL-0424 field wiring

Emerson DeltaV SIS DO810: Competitor SIL 3 output module—often cross-shopped but lacks Honeywell’s native Experion integration

ABB AC 800F FDO 120: Functional alternative in ABB 800xA SIS systems

GE RV33-1: Non-SIL general-purpose output—not suitable for safety functions; used only in BPCS

Honeywell Experion Safety Builder: Engineering software for configuring FC-SDOL-0424 logic and diagnostics

Installation, Maintenance, and Full-Cycle Support

Installation of the FC-SDOL-0424 requires mounting into a certified Safety Manager I/O chassis, connecting to redundant 24 VDC power rails, and wiring field devices to the companion terminal block (e.g., FC-TERM-24). All safety loops must be validated per IEC 61511. including proof test coverage.

Maintenance is simplified by front-panel LEDs (green = healthy, red = fault) and automated diagnostics accessible via Experion. Modules support hot-swap in redundant configurations, minimizing process downtime. Honeywell recommends full functional testing every 12–24 months, depending on demand rate.

We provide fully tested, factory-certified FC-SDOL-0424 modules with original firmware, calibration certificates, and compatibility verification for all Safety Manager generations. Each unit undergoes SIL 3 functional validation, including contact resistance, isolation, and fail-safe response time tests.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: