Description

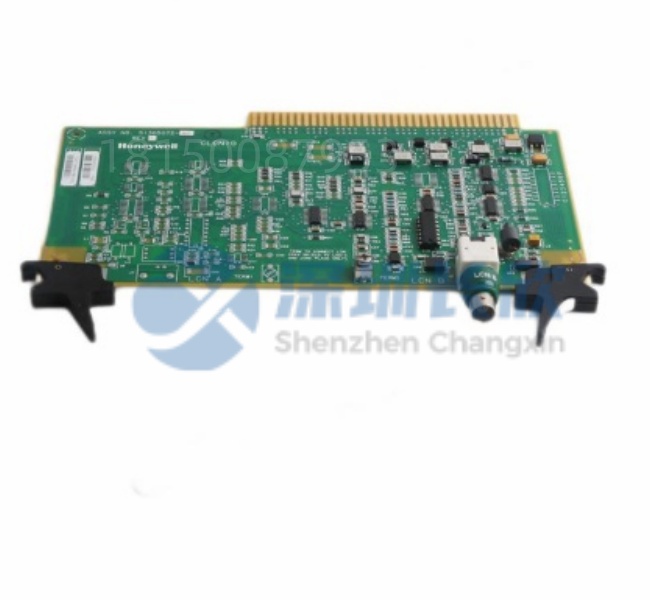

The Honeywell 51305072-600 is an 8-channel analog input (AI) module engineered exclusively for the Experion® Safety Manager—Honeywell’s TÜV-certified safety instrumented system (SIS) platform. Designed to meet SIL 3 requirements per IEC 61508/61511. this high-integrity module acquires critical process variables such as pressure, temperature, and flow from 4–20 mA transmitters (with optional HART communication) in emergency shutdown (ESD), fire & gas (F&G), and burner management systems.

Built with redundant signal paths, continuous self-diagnostics, and robust channel-to-channel isolation, the Honeywell 51305072-600 ensures that safety-critical data is captured accurately—even under fault conditions—enabling reliable, fail-safe decisions when seconds count.

Application Scenarios

At a deepwater offshore platform in the Gulf of Mexico, a high-pressure separator was protected by a Safety Instrumented Function (SIF) requiring SIL 3 integrity. Three differential pressure transmitters fed into a Honeywell 51305072-600 module on a redundant Safety Manager chassis. During a routine proof test, the module’s built-in diagnostics detected a subtle drift in one transmitter’s zero point—before it triggered a spurious trip. Maintenance replaced the sensor during scheduled downtime, avoiding a potential $12M/day production loss. The platform’s safety lead stated: “The Honeywell 51305072-600 doesn’t just read signals—it safeguards our license to operate.”

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Dual Independent Signal Paths per Channel

Each input on the Honeywell 51305072-600 uses two separate analog-to-digital converters and processing paths. A comparator validates both readings—if they diverge beyond tolerance, a fault is declared, preventing undetected dangerous failures.

Innovation Point 2: Advanced Open-Wire & Loop Integrity Detection

Unlike basic AI cards, the Honeywell 51305072-600 injects test currents to detect broken wires, loose terminals, or degraded connections—critical for safety loops that must function after months of dormancy.

Innovation Point 3: Native HART Integration in Safety Layer

The module reads HART device status, PV, and diagnostics without compromising safety integrity—enabling predictive maintenance while maintaining SIL compliance.

Innovation Point 4: Seamless Coexistence with Control Layer

Though part of the Safety Manager, the Honeywell 51305072-600 shares the same physical I/O architecture (R510 carrier, FTA blocks) as Experion PKS—reducing cabinet footprint and simplifying engineering.

Application Cases and Industry Value

A hydrogen production plant in South Korea upgraded its aging hardwired ESD system to a fully integrated Experion Safety Manager solution using Honeywell 51305072-600 modules for reactor temperature monitoring. During commissioning, the system correctly rejected a simulated single-point failure—proving its 1oo2D (one-out-of-two with diagnostics) architecture worked as designed. The plant achieved full SIL 3 certification from KOSHA and reduced proof test time by 60% thanks to automated diagnostics.

In a LNG export terminal, Honeywell 51305072-600 modules monitor cryogenic valve position feedback in the loading arm ESD system. Despite ambient temperatures dropping below -160°C, the modules maintained accuracy—thanks to industrial-grade component selection and thermal compensation algorithms.

Related Product Combination Solutions

Experion Safety Manager Controller (e.g., 51305001-100) – Host safety logic solver

R510 Safety I/O Carrier (51305025-150) – Mounting base for 51305072-600 with FTE and power

FTA-TBxx Safety Terminal Blocks – e.g., FTA-TB16-S, intrinsically safe field wiring interface

51305073-600 – 8-channel safety analog output (AO) counterpart

51305081-600 – Safety digital input (DI) module for switch/relay signals

Safety Builder Studio – Engineering tool for configuring SIFs using 51305072-600

Experion FTE Network – Provides redundant communication between Safety Manager and I/O

Installation, Maintenance, and Full-Cycle Support

Install the Honeywell 51305072-600 onto an R510 Safety I/O carrier within a properly grounded Safety Manager cabinet. Field wiring connects via certified safety terminal blocks (e.g., FTA-TB16-S). Ensure loop-powered transmitters are compatible with the module’s passive input design. Use twisted, shielded pair cables with single-point grounding to minimize noise.

For maintenance, use Safety Builder Studio to view real-time channel health: “Valid,” “Open Wire,” “Short,” or “Diagnostic Fault.” Each channel has an LED indicator for local verification. In redundant systems, hot-swap is permitted after confirming backup controller readiness.

Every Honeywell 51305072-600 we supply is factory-tested against SIL 3 diagnostic coverage requirements, including fault injection and response validation. Units include full traceability to Honeywell’s functional safety lifecycle documentation and come with a 12-month warranty.

Contact us for a complete Safety I/O solution—including FMEDA reports, SIL verification packages, and certified configuration support—for your next Safety Instrumented System project using the Honeywell 51305072-600.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: