Description

Description

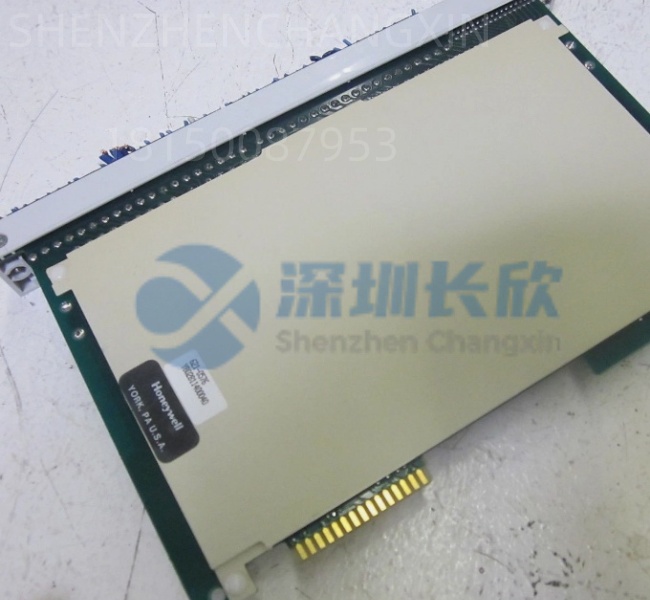

The Honeywell 621-0576 is a 24V DC I/O (Input/Output) module manufactured by Honeywell, designed to interface between a control system (like a PLC or DCS) and field devices . It provides 24 input channels and 8 output channels with a 2A rating, serving as a critical component for digital signal handling in industrial automation applications .

Application Scenarios

In an automotive manufacturing plant, a production line’s conveyor system must synchronize the movement of robotic welders with chassis positioning. A failure in the control signal interface can cause costly stoppages. The Honeywell 621-0576 module in this scenario acts as the reliable nerve center; it receives 24V DC signals from proximity sensors detecting the chassis position (inputs) and executes commands from the main controller to activate the robotic welders’ solenoids (outputs). Its robust design ensures that electrical noise from large motors does not cause spurious signals, while its high channel count allows a single 621-0576 to manage a significant section of the line, simplifying the control cabinet layout and reducing wiring complexity .

Parameter

Technical Principles and Innovative Values

High-Density I/O Configuration: The Honeywell 621-0576 integrates a substantial number of I/O points (24 inputs and 8 outputs) into a single module. This high channel density maximizes control cabinet space efficiency, allowing for a more compact system design and reducing the number of modules required for a given application, which simplifies wiring and lowers overall system cost .

Sink/Source Versatility: The module is described as a “SINK IN/OUTPUT” module, indicating its capability to handle both sinking and sourcing current configurations . This flexibility is a significant advantage, allowing the 621-0576 to interface seamlessly with a wide range of field devices (e.g., sensors, actuators) regardless of their current flow design, thereby increasing its applicability across different automation architectures and reducing the need for specific interface components .

Robustness for Industrial Environments: Designed for 24V DC systems, the module is built to withstand the typical electrical noise, voltage fluctuations, and harsh conditions found on industrial factory floors. The 2A current rating per output ensures it can directly drive a variety of actuators and relays reliably, providing strong operational integrity for continuous production environments .

Application Cases and Industry Value

A documented case involves using the Honeywell 621-0576 in a packaging machinery line. The machine experienced intermittent faults due to signal interference from variable-frequency drives (VFDs) controlling its motors. After replacing a less robust interface module with the 621-0576. the line’s reliability improved significantly. The 621-0576’s design effectively rejected the electrical noise, eliminating the spurious signals that previously caused unplanned stops. This resulted in a measurable increase in Overall Equipment Effectiveness (OEE) for the end-user, highlighting the module’s value in improving production efficiency and reducing downtime .

Related Product Combination Solutions

For a complete control solution, the Honeywell 621-0576 is typically used alongside several related components :

Honeywell PLCs or DCS Controllers (e.g., Experion Series): These are the central processors that send and receive signals via the 621-0576 module.

Power Supply Units (e.g., 24V DC Rails): A stable and adequately rated 24V DC power supply is essential to operate the 621-0576 and its connected field devices.

Field Devices: Sensors (e.g., proximity, photoelectric) connect to the input channels, and actuators (e.g., solenoid valves, motor starters) connect to the output channels of the 621-0576.

Termination Boards or Cabinets: Physical mounting and wiring accessories are needed to install the module and connect field wiring.

Spare or Redundant Modules: For critical applications, having a spare 621-0576 on hand or configuring a redundant system minimizes downtime in case of a failure.

Installation, Maintenance, and Full-Cycle Support

Installation of the Honeywell 621-0576 requires a qualified technician to mount the module on a DIN rail within an appropriate enclosure, ensuring correct wiring of the 24V DC power supply and all field devices to the specified terminals. Proper grounding and adherence to local electrical codes are critical for safe and reliable operation .

Routine maintenance primarily involves visual inspection for physical damage and monitoring the system’s diagnostic indicators for any faults. If a module fails, many suppliers offer refurbishment services. The module is designed to be replaceable, and suppliers often provide expedited global shipping to minimize downtime. Support services can include extended warranties, maintenance contracts, and comprehensive repair services for even severely damaged units, often backed by a 12-month warranty on repairs .

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email:

Description

Description