Description

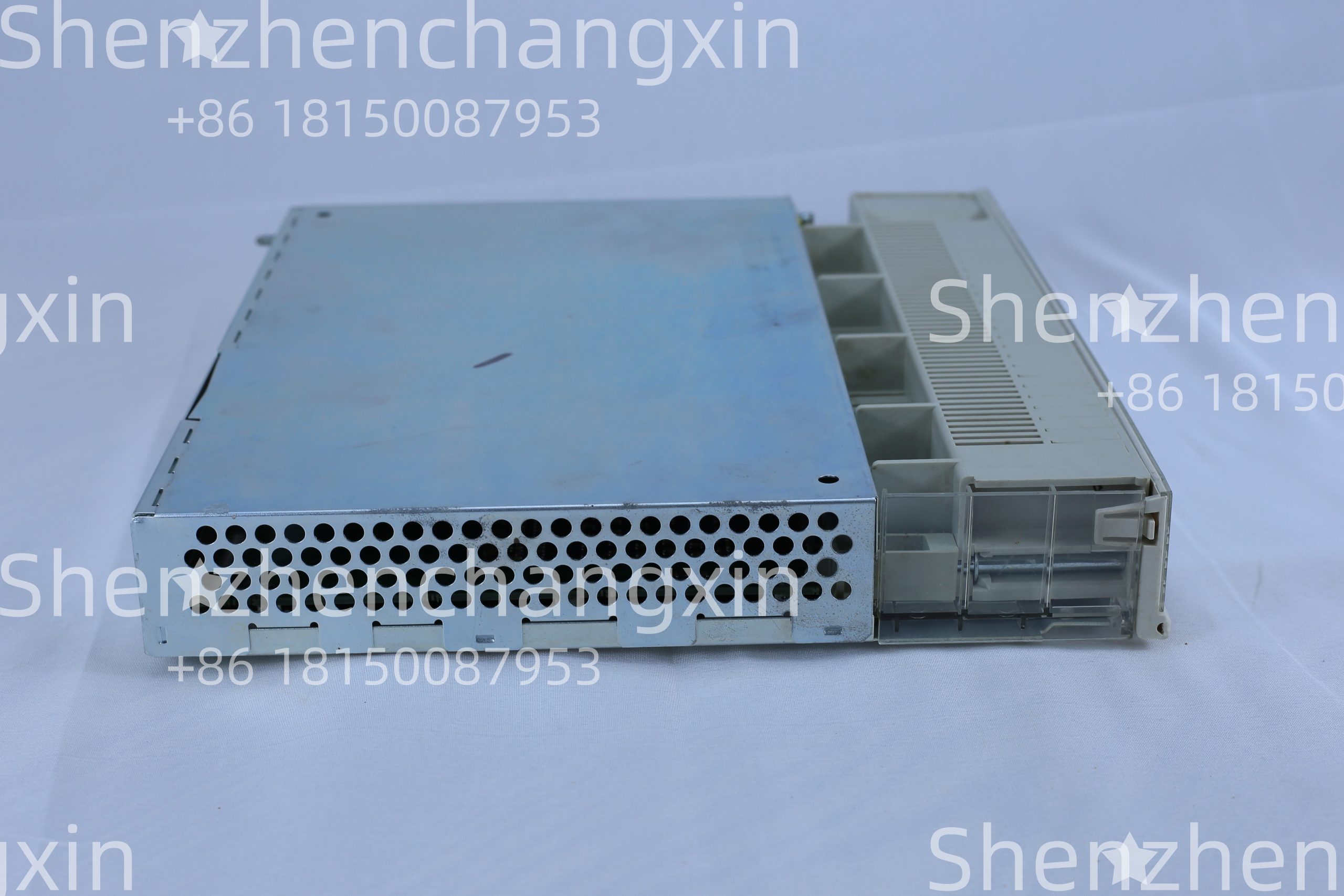

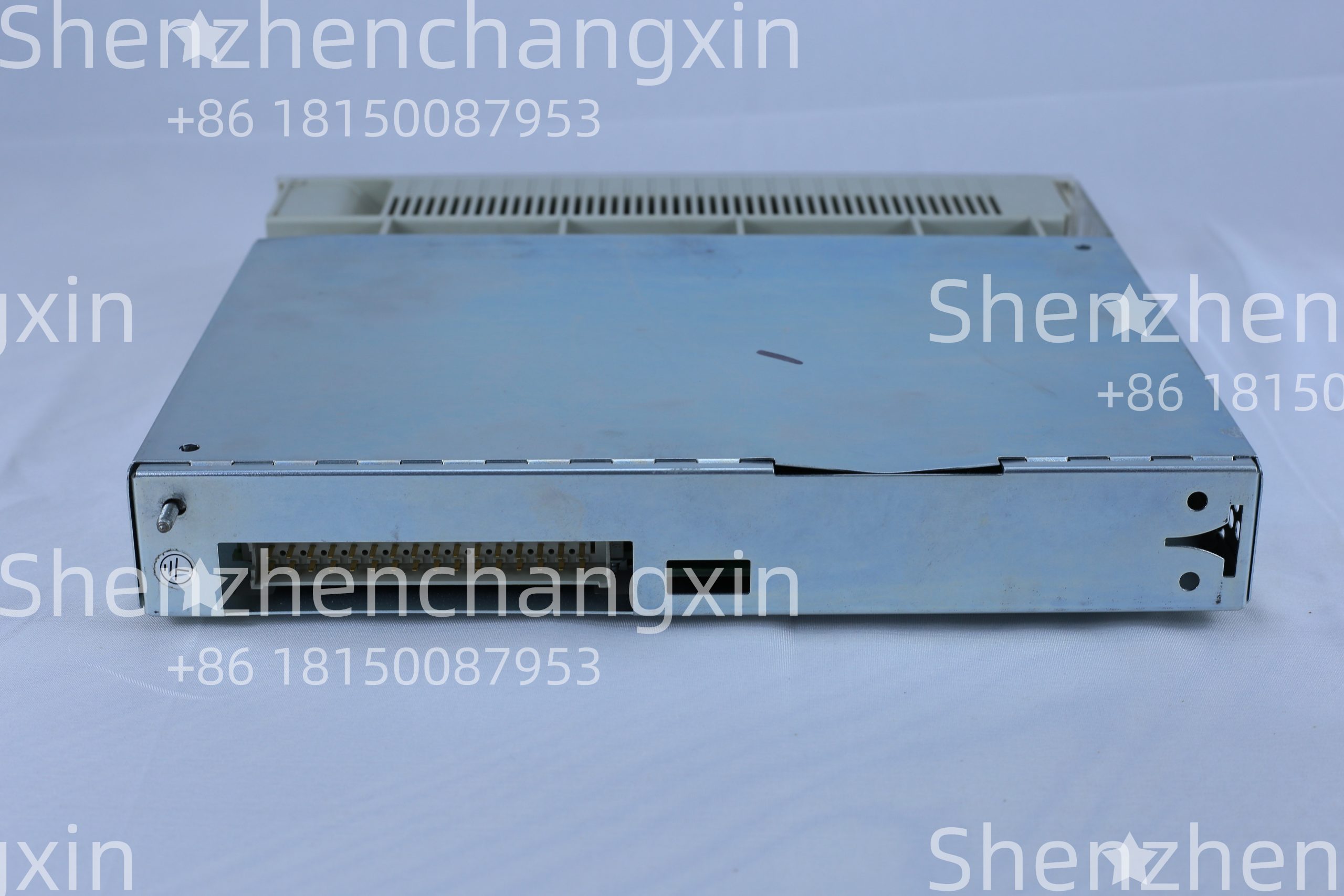

The ABB DI620 is a robust, 16-channel digital input module engineered for the ABB AC 800M programmable automation controller (PAC) platform within the System 800xA architecture. Designed to interface with field devices such as limit switches, pushbuttons, relay contacts, and proximity sensors, it reliably converts discrete on/off signals into secure, time-stamped process data for logic execution, safety interlocks, and operator awareness.

With galvanic isolation, surge protection, and support for both sink and source wiring, the DI620 delivers industrial-grade reliability in demanding applications across power generation, oil & gas, mining, and heavy manufacturing.

Application Scenarios

At a Scandinavian biomass power plant, false “boiler door open” alarms triggered unnecessary turbine trips—costing over €50.000 per incident in lost revenue and restart fuel. The legacy PLC input card was susceptible to ground loops from nearby motor starters. After upgrading to the DI620. engineers leveraged its channel-to-channel isolation and 5 kV transient suppression to eliminate spurious signals. Combined with AC 800M’s event timestamping (±1 ms accuracy), maintenance teams could now correlate alarms with actual door actuation—not electrical noise. In one year, unplanned outages dropped by 90%. For this facility, the DI620 wasn’t just an I/O module—it was the guardian of operational truth.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: True Industrial Hardening for Noisy Environments

The DI620 features opto-isolators rated for 5 kV and built-in RC filtering—rejecting transients from VFDs, solenoids, and arc welders that would overwhelm standard DI modules.

Innovation Point 2: Flexible Wiring Without Hardware Changes

Unlike fixed-sink/source modules, the DI620 supports either configuration through terminal wiring alone—no jumpers or DIP switches—accelerating panel build and future modifications.

Innovation Point 3: Precision Event Logging for Root-Cause Analysis

When paired with AC 800M firmware v5+, the DI620 timestamps every state change with 1 ms resolution. This data feeds directly into System 800xA Sequence of Events (SOE) for forensic troubleshooting.

Innovation Point 4: Hot-Swap Ready for Zero-Downtime Maintenance

Technicians can replace a faulty DI620 during live operation. The system retains logic integrity while the new module auto-configures using stored parameters from the I/O station.

Application Cases and Industry Value

A South American copper mine integrated the DI620 into its conveyor belt control system to monitor emergency stop pull-cord switches across 12 km of underground tunnels. Previously, moisture-induced leakage currents caused phantom stops. The DI620’s high input impedance (>10 kΩ off-state) and wetting current design ensured only deliberate switch closures registered. Over two years, false stops fell from 14/month to zero—boosting throughput by 7%. Mine engineers now specify the DI620 as standard for all critical discrete inputs, citing its “set-and-forget” reliability in harsh, humid conditions.

Related Product Combination Solutions

AC 800M CPU (e.g., PM865): Central controller that processes digital states from DI620 for logic execution.

DO620: 16-channel digital output module—ideal companion for interlock-driven actuator control.

TB570 Baseplate: High-density carrier enabling hot-swap installation of DI620 in compact cabinets.

CI854 Communication Interface: Links remote I/O stations (with DI620) to AC 800M over fiber or copper.

System 800xA Engineering Workplace: Configures channel filters, diagnostics, and SOE mapping for DI620.

XVC772A102: Analog input module often deployed alongside DI620 in hybrid process/machine control panels.

Control Builder M: ABB’s programming environment where DI620 tags are declared and linked to safety logic.

DI610: Lower-density (8-channel) variant for applications requiring fewer inputs per module.

Installation, Maintenance, and Full-Cycle Support

Installing the DI620 begins with mounting it in a TB550 or TB570 baseplate within an AC 800M I/O station. Field wiring uses standard 24 VDC discrete signals—ensure shielded cable for long runs near power conductors, with shields grounded at the cabinet end. Input filtering can be tuned in Control Builder M to match switch type (e.g., 5 ms for mechanical contacts, 0.5 ms for solid-state).

Maintenance is simplified by front-panel LEDs that indicate real-time channel status and module health. If replacement is needed, enable hot-swap mode in the I/O station configuration, remove the module, and insert the new unit—the system restores I/O mapping automatically. Periodic checks include verifying input voltage under load and inspecting terminals for corrosion in humid environments.

Every DI620 we supply is 100% authentic, functionally tested across full voltage and temperature ranges, and backed by a 12-month warranty. Our ABB-certified engineers provide commissioning support, configuration templates, and lifecycle management—ensuring your discrete signals remain trustworthy from startup to decommissioning.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: