📝 Product Description

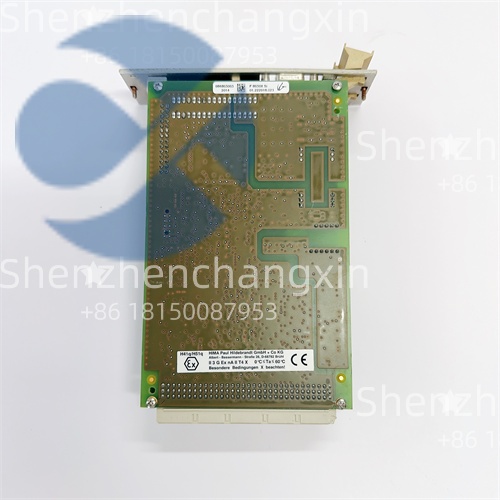

The HIMA Z7149 is a Digital I/O Module manufactured by HIMA, a leading specialist in safety-critical automation. This module is a key component within the HIMax series of safety instrumented systems (SIS), designed to provide a reliable interface between the central safety controller and field devices like emergency stop buttons, solenoid valves, and pressure switches. It is engineered for high reliability in harsh conditions, making it essential for applications where functional safety is paramount, such as emergency shutdown systems in oil and gas facilities.

Input Voltage: 24 VDC

Operating Temperature: -40°C to +85°C

Safety Certification: SIL 3 (IEC 61508)

Number of Channels: 16

⚙️ Technical Specifications

🏭 Product Overview

The HIMA Z7149 is a specialized safety I/O module that acts as a critical gateway in a Safety Instrumented System (SIS). Its primary function is to reliably acquire digital signals from field sensors and transmit commands to final elements based on the logic solved by the safety controller. As part of the HIMax family, the Z7149 is designed from the ground up for safety, ensuring that safety functions are executed with the high integrity required to protect people, assets, and the environment. Its robust construction and wide operating temperature range allow it to perform reliably in the demanding environments typical of process industries like oil and gas, chemical, and power generation .

💡 Main Features and Advantages

High Functional Safety Integrity: The HIMA Z7149 is engineered and certified for use in safety systems requiring up to SIL 3 according to IEC 61508. Its design includes features like internal diagnostics and cross-circuit comparison to prevent dangerous failures, ensuring that safety functions are performed correctly when needed .

High Availability with Diagnostics and Hot-Swap: The module includes extensive built-in diagnostics that continuously monitor its health and the field wiring, detecting faults such as short circuits or wire breaks. Furthermore, it supports hot-swap capability, allowing it to be replaced without shutting down the entire safety system, which maximizes plant availability and reduces downtime .

Robust and Reliable Design: Built for harsh industrial environments, the Z7149 operates reliably across a wide temperature range from -40°C to +85°C and has high immunity to electromagnetic interference (EMI) and vibrations. This ensures long-term reliability and stable operation in critical applications .

Seamless Integration: The module is designed for seamless integration within the HIMA safety controller ecosystem. It supports mainstream industrial protocols like PROFIBUS and Ethernet/IP, acting as a gateway to integrate the safety system into broader automation architectures, such as those from Siemens or Schneider, protecting existing investments .

🌍 Application Fields

The HIMA Z7149 is deployed in industries where failure is not an option. In oil and gas refineries and offshore platforms, it is a core component of Emergency Shutdown (ESD) and Fire & Gas (F&G) systems, where it interfaces with sensors and valves to safely isolate sections of the process in case of a detected hazard . In power generation plants, particularly in turbine control and burner management systems, the module ensures safe operation by processing critical trips signals . It is also used in chemical and pharmaceutical plants for safety interlocks on reactors and in rail transportation for signaling systems, highlighting its versatility across high-hazard industries .

🔍 Selection and Use Suggestions

When selecting the HIMA Z7149. it is crucial to first define the Safety Instrumented Functions (SIFs) and the required Safety Integrity Level (SIL) to ensure the module is appropriate for the application. You must also verify system compatibility with the existing HIMA HIMax controller and baseplate . For maintenance, leverage the module’s diagnostic capabilities and hot-swap feature. Always follow strict installation guidelines, using proper wiring practices and ensuring the module is correctly configured via dedicated engineering tools like SILworX to maintain system integrity and certification .

❓ Frequently Asked Questions (FAQ)

Q1: What is the primary function of the HIMA Z7149 module?

A1: The primary function of the HIMA Z7149 is to serve as a digital input/output interface within a HIMA safety system. It reliably connects field devices (sensors, switches, valves) to the safety controller, enabling the execution of critical safety functions .

Q2: Can the Z7149 module be replaced without stopping the system?

A2: Yes, the Z7149 supports hot-swapping in a properly configured redundant system. This allows a faulty module to be replaced while the system remains operational, which is vital for maintaining high availability in continuous processes .

Q3: What is the difference between the Z7149 and a standard PLC I/O module?

A3: Unlike standard PLC I/O, the Z7149 is specifically designed and certified for functional safety (up to SIL 3). It has a architecture with built-in diagnostics, redundancy support, and isolation designed to prevent dangerous failures, which is not typically found in standard modules .

🛠️ Installation and Maintenance

Installation and Commissioning: Before installing the HIMA Z7149. ensure the system power is off. The module is designed for mounting on a DIN rail or within a HIMA baseplate. Correct wiring is critical; use shielded cables and follow the manufacturer’s diagrams to prevent noise interference. During commissioning, the module must be configured using HIMA’s dedicated software (e.g., SILworX) to set parameters and alarm thresholds .

Routine Maintenance: Maintenance focuses on monitoring the module’s status via its LED indicators and the system’s diagnostic software. Regular checks should be performed to look for signs of overheating, loose terminals, or corrosion. The module’s self-test capabilities should be used during planned shutdowns to verify all channels are functioning correctly. Always replace components with genuine HIMA parts to maintain safety certification .

💎 Summary

The HIMA Z7149 is a high-integrity digital I/O module that forms the reliable connection between a HIMA safety controller and the field devices in a Safety Instrumented System. Its robust design, SIL 3 certification, and advanced features like comprehensive diagnostics and hot-swap support make it an ideal choice for protecting critical processes in industries such as oil and gas, power generation, and chemicals. Proper selection, installation, and maintenance are key to leveraging its full potential for ensuring operational safety and availability.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: