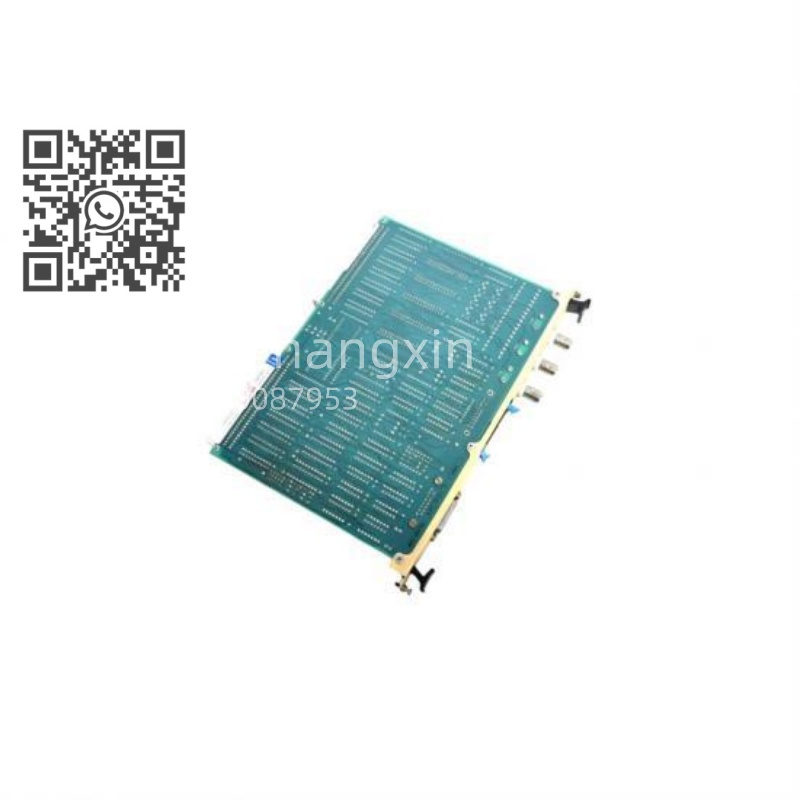

Description

The ABB VD86-GE1 (57779331) is a robust industrial PC module designed for demanding automation environments. Functioning as a core component for operator interfaces and industrial computing, it provides the processing power and connectivity needed for visualization, data handling, and supervisory control tasks within complex ABB system architectures.

Application Scenarios

In a highly automated automotive paint shop, precise control of robot trajectories, paint mixing, and oven temperatures is critical. Operators and engineers need a centralized, ruggedized station to visualize the entire process, acknowledge alarms, and adjust parameters. The ABB VD86-GE1 module serves as the computing engine inside an industrial operator station. It runs the visualization software, connects to multiple controller networks (like robots and PLCs), and drives the high-resolution display. When a paint circulation pump shows a pressure deviation, the VD86-GE1 processes the alarm, displays its location on the schematic, and logs the event. Its industrial-grade construction withstands the ambient vibrations and temperature fluctuations of the plant floor, ensuring continuous operation where a commercial PC would fail. This illustrates its role in solving the need for reliable, centralized human-machine interaction (HMI) in harsh, mission-critical industrial settings.

Parameter

Technical Principles and Innovative Values

The ABB VD86-GE1 distinguishes itself from commercial IT hardware through engineering choices that prioritize long-term reliability and deterministic performance in industrial settings.

Innovation Point 1: Enhanced Mechanical & Component Robustness. Unlike standard PCs, the VD86-GE1 utilizes industrial-grade components soldered and secured to withstand significant vibration and shock. Its design likely includes conformal coating on the motherboard to protect against humidity and corrosive atmospheres. Storage is typically a ruggedized solid-state drive (SSD) with no moving parts, eliminating a common point of failure (hard disk drives) and ensuring faster, more reliable boot and operation in environments with constant vibration.

Innovation Point 2: Optimized Thermal Management for Passive Cooling. The module is engineered for efficient heat dissipation without relying on dust-prone, failure-prone standard fans. It likely uses extensive heat sinks and a chassis designed as a heat spreader, allowing for convection or controlled forced-air cooling. This passive cooling approach minimizes maintenance, reduces acoustic noise, and prevents dust ingress—a major cause of overheating and failure in standard computers used in industrial settings.

Innovation Point 3: Long-Term Supply & Component Stability. ABB commits to long product lifecycles for industrial components like the VD86-GE1. This means the exact processor, chipset, and I/O controllers are sourced and managed for availability over a decade or more. This stability is critical for system integrators and end-users, as it allows for predictable maintenance, spare parts availability, and avoids costly software re-validation often required when upgrading to a new PC architecture with different drivers.

Application Cases and Industry Value

Case Study: Centralized Control Room Upgrade for a Wastewater Treatment Plant

A municipal wastewater treatment plant operated with a distributed control system using aging, disparate operator stations that were slow, prone to crashes, and no longer supported.

Solution & Outcome: The plant consolidated control into a new central room featuring modern, large-screen displays powered by ABB VD86-GE1 industrial PC modules. These modules were installed in a redundant server rack configuration. They run advanced process visualization software, aggregating data from across the plant—from inlet pumping to final clarifiers. The VD86-GE1’s reliability eliminated the daily crashes, and its processing power enabled advanced features like real-time energy consumption dashboards and predictive trend analysis for pump health. The plant manager noted: “The VD86-GE1-based system provides a single, reliable pane of glass for our operators. We’ve improved response time to incidents by 40%, and the system’s uptime is now measured in years, not days. The long-term support commitment was a key factor in our selection.”

Related Product Combination Solutions

The ABB VD86-GE1 operates as the central computing node within a broader ecosystem of automation products.

Industrial Monitors & Touch Panels (e.g., ABB CP600 series): These are the display interfaces driven by the VD86-GE1. providing the visual and tactile interface for operators.

AC 800M / 800xA Controllers: The primary process controllers that communicate process data to the visualization software running on the VD86-GE1 via OPC or native protocols.

Industrial Networking Switches: Provide the robust Ethernet backbone that connects the VD86-GE1 to controllers, other stations, and plant networks.

System 800xA / Other HMI Software: The engineering and runtime visualization software environment that is installed and executed on the VD86-GE1 module.

Redundant Power Supplies (e.g., UNS0868B-P V2): Provide clean, fault-tolerant 24V DC power to the cabinet housing the VD86-GE1. ensuring continuous operation.

Keyboard/Video/Mouse (KVM) Extenders: Allow the VD86-GE1 to be located in a secure server room while the operator interfaces are in the control room.

Historical Data Servers: Often separate, larger industrial PCs that archive process data; the VD86-GE1 may act as a client or gateway to these systems.

Installation, Maintenance, and Full-Cycle Support

Installation of the ABB VD86-GE1 involves mounting it securely in a standard 19-inch rack or industrial enclosure, ensuring adequate clearance for airflow. Connections include power (typically 24V DC), Ethernet for control network and plant network, and possibly a display cable if configured as a dedicated HMI. The initial setup involves installing or loading the approved operating system and application software image. Its modular design simplifies integration, and its standardized interfaces ensure compatibility with industrial peripherals.

Routine maintenance focuses on preventative measures: ensuring ventilation paths are clear of dust, verifying backup power systems (UPS), and performing regular software/image backups. The VD86-GE1’s health can often be monitored via its operating system or network management tools. Should a hardware failure occur, the module can be replaced as a unit. The failed unit is removed, and a new one is installed, with the pre-configured software image restored from backup. This minimizes system downtime. We provide comprehensive support for the VD86-GE1. from initial sizing and software compatibility guidance to supplying genuine replacement units and long-term component availability. Our services ensure your industrial computing infrastructure remains a reliable foundation for your operations.

Contact us for expert assistance in specifying, configuring, and sourcing the ABB VD86-GE1 industrial PC module for your critical control and visualization applications.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: