Description

Application Scenarios

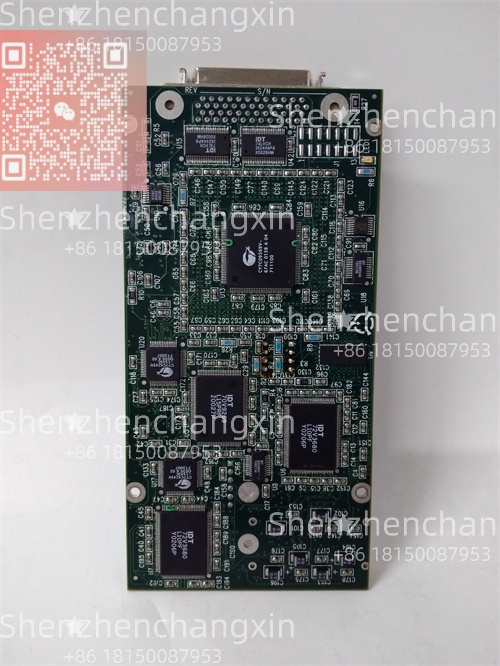

In a high-speed electronic component assembly line, a “pick-and-place” gantry system must place microscopic chips onto a circuit board with micron-level accuracy at a rate of over 10.000 components per hour. The challenge involves coordinating four servo axes (X, Y, Z, and Θ rotation) with smooth, s-curve acceleration profiles to minimize vibration and settling time. The PMC-6130-J 0100RSDPMC-J motion controller is the solution. It executes complex look-ahead trajectory planning, dynamically adjusting the path to maintain speed while ensuring perfect stop accuracy. This application showcases the controller’s value in solving the critical pain points of throughput bottlenecks, placement inaccuracy, and mechanical wear caused by suboptimal motion control.

Parameter

Technical Principles and Innovative Values

The PMC-6130-J 0100RSDPMC-J is engineered to master the physics of motion, translating complex path planning into flawless mechanical execution.

Innovation Point 1: Advanced Look-Ahead and Jerk Control. The controller employs sophisticated algorithms that “look ahead” dozens or hundreds of motion segments in the program buffer. This allows it to calculate the optimal acceleration and deceleration profile for each segment, minimizing “jerk” (the rate of change of acceleration). This results in smoother motion, reduced mechanical vibration and wear, higher possible machine speeds, and improved final positioning accuracy.

Innovation Point 2: Highly Flexible Network-Centric Architecture. Beyond simple pulse output, the PMC-6130-J likely supports real-time industrial Ethernet protocols (like EtherCAT or PROFINET IRT) or high-speed fieldbuses. This transforms it from a standalone controller into a network master, enabling distributed clock synchronization with drives and I/O at the sub-millisecond level. This architecture simplifies wiring, improves diagnostics, and allows for highly scalable, synchronized multi-axis systems.

Innovation Point 3: Unified Development Environment. A key differentiator is its integration of motion control programming with logic sequencing. Using a platform that combines PLC logic (IEC 61131-3) with advanced motion function blocks, engineers can develop the entire machine’s sequence and motion in one unified software suite. This eliminates communication lags and integration issues between separate PLC and motion controllers, drastically reducing development and debugging time.

Innovation Point 4: On-the-Fly Parameter Adjustment and Adaptive Control. For applications like winding, flying cut, or press feeds, the controller can dynamically adjust parameters (like gearing ratios or cam profiles) in real-time based on sensor input or calculated values. This adaptive control capability allows machines to respond to variations in material or process conditions without stopping, significantly boosting productivity and product quality.

Application Cases and Industry Value

Case 1: Revolutionizing a Rotary Knife Cutting Machine

A converter of flexible materials (films, foils) needed to upgrade a rotary cutter to handle new, delicate materials without sacrificing speed or creating ragged edges. The mechanical line shaft and old controller were replaced with a direct-drive system controlled by a PMC-6130-J 0100RSDPMC-J. Using its electronic line shafting and high-speed registration input, the controller synchronizes the knife servo perfectly to the web speed, adjusting the phase in real-time based on a mark reading sensor. The plant manager reported a 40% reduction in material waste due to perfect cuts, a 25% increase in line speed, and the ability to change cut lengths instantly via software, eliminating mechanical changeover downtime.

Case 2: Enabling a Complex 5-Axis Laser Welding Cell

A manufacturer of automotive battery packs required a 5-axis system to perform intricate, hermetic laser welds on aluminum enclosures. The complex 3D paths and precise speed control were beyond standard CNC capabilities. A system built around the PMC-6130-J 0100RSDPMC-J, controlling five linear and rotary servo axes, achieved the necessary performance. The application engineer emphasized the controller’s ability to perform smooth 5-axis linear interpolation while precisely modulating laser power as a function of path speed (power control). This resulted in flawless, consistent weld seams, a 99.8% first-pass yield rate, and the flexibility to program new weld paths in hours instead of days.

Related Product Combination Solutions

The PMC-6130-J 0100RSDPMC-J acts as the command center of a high-performance motion system. Essential complementary components include:

Digital Servo Drives & Motors: High-performance servo systems that receive command signals from the PMC-6130-J and provide the torque and position feedback to close the loop.

Programmable HMI/Operator Panel: Provides the user interface for operators to start cycles, input parameters, and view diagnostics from the motion controller.

I/O Expansion Modules: Additional digital and analog I/O modules to handle more sensors, solenoids, and peripheral devices than the controller’s built-in I/O can support.

Power Supply Unit (PSU): A stable, regulated power supply to provide clean power to the PMC-6130-J controller and its associated logic circuits.

Programming & Configuration Software: The proprietary or standards-based (e.g., CODESYS) IDE used to program motion sequences, logic, and configure all parameters of the PMC-6130-J.

Cables & Connectors: High-quality shielded cables for encoder feedback, drive command signals, and communication buses to ensure signal integrity in noisy industrial environments.

Machine Safety Controller (e.g., Safety Relay, PLC): A separate, certified safety system (like an ABB SafeTM or Pilz PNOZ) that interfaces with the PMC-6130-J’s general outputs/inputs to implement safety functions like Safe Torque Off (STO) and safe stop monitoring.

Installation, Maintenance, and Full-Cycle Support

Installation begins with securely mounting the PMC-6130-J 0100RSDPMC-J in a protected control cabinet with adequate ventilation. Correct wiring is critical: clean power must be supplied, communication and feedback cables must be properly shielded and routed away from power lines, and all grounds must be connected to a common star point to avoid noise. Commissioning is done through the dedicated software, involving configuration of each axis (motor/drive parameters, tuning servo loops), setting up I/O, and programming the motion sequences. The modular and well-documented design facilitates systematic troubleshooting.

Routine maintenance is primarily preventive. This includes checking for loose connections, ensuring cooling fans (if present) are unobstructed, and backing up all controller parameters and application programs. Periodic verification of axis accuracy may be required. The controller’s health is often monitorable via software diagnostics. We provide comprehensive support for the PMC-6130-J, from initial system design and component selection assistance to commissioning guidance. Our services also include supplying fully tested hardware, access to software and documentation, and expert technical support to ensure your motion application achieves optimal performance and longevity.

Contact us to discuss your motion control challenge and how the PMC-6130-J 0100RSDPMC-J can provide a precise, powerful, and programmable solution.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: