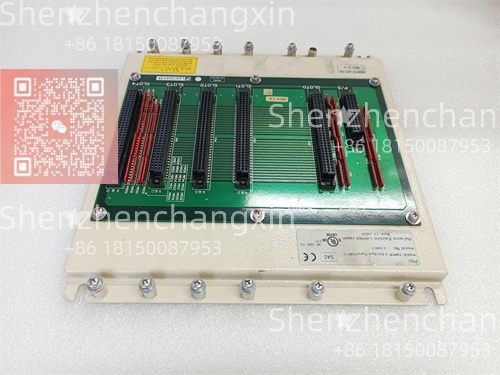

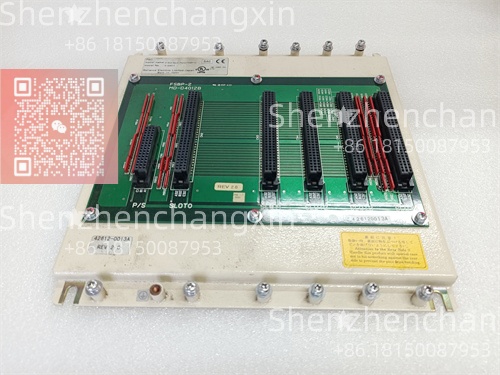

Description

Application Scenarios

At a regional food processing plant in the Midwest, an aging belt conveyor system caused inconsistent product spacing and frequent jams due to fixed-speed operation. Replacing the direct-on-line starter with a RELIANCE ELECTRIC S-D4012 enabled operators to fine-tune line speed via the front-panel keypad and implement soft-start/stop ramps. The S-D4012’s built-in PID loop—configured using feedback from a proximity sensor—automatically adjusted motor speed to maintain optimal product flow during upstream fluctuations. Within three months, jam-related downtime dropped by 65%, and energy consumption fell by 18% thanks to reduced mechanical stress and optimized runtime. Maintenance staff praised the S-D4012 for its “plug-and-play simplicity” and clear fault diagnostics—proving that even entry-level drives can deliver transformative operational value.

Technical Principles and Innovative Values

Innovation Point 1: Single-Phase to Three-Phase Conversion with Full Torque – Unlike basic phase converters, the S-D4012 uses advanced PWM technology to deliver balanced three-phase output from single-phase input, enabling full-rated torque at low speeds—ideal for retrofitting three-phase motors in locations without three-phase service.

Innovation Point 2: Integrated EMC Compliance Out of the Box – The built-in Class B EMI filter ensures compliance with EN 61800-3 without external components, reducing cabinet noise and simplifying certification for OEMs.

Innovation Point 3: Smart Auto-Tuning for Motor Adaptation – At startup, the S-D4012 automatically measures motor parameters (stator resistance, leakage inductance) to optimize V/f curves—improving low-speed stability and reducing motor heating by up to 15%.

Innovation Point 4: Embedded PID for Closed-Loop Simplicity – Eliminates the need for external controllers in pressure, flow, or level applications; users can connect a 4–20 mA or 0–10 V feedback signal directly to the drive’s analog input and enable internal PID regulation in minutes.

Application Cases and Industry Value

A small HVAC contractor in California retrofitted rooftop unit fans across 12 commercial buildings using the RELIANCE ELECTRIC S-D4012 to comply with Title 24 energy codes. Each drive was configured for night setback and demand-controlled ventilation using a simple 0–10 V signal from the building management system. The S-D4012’s quiet operation (adjustable carrier frequency up to 16 kHz) and minimal harmonic distortion prevented interference with nearby electronics. Post-installation audits showed average fan energy savings of 32%, with payback under 14 months. One facility manager noted, “We expected complexity—but the S-D4012 worked flawlessly from day one, and our tenants never heard a thing.”

Related Product Combination Solutions

S-D4022: 2 HP version of S-D4012. for higher-torque applications like small compressors or agitators.

PowerFlex 4M: Rockwell’s modern successor with enhanced communication (EtherNet/IP option) and global voltage support.

20-COMM-R: RS-485 communication adapter for integrating S-D4012 into Allen-Bradley PLC networks.

199-DRIVE-KIT: External keypad kit for remote mounting when the S-D4012 is installed inside an enclosure.

199-EMC-FILTER: Additional external filter for installations requiring Class A emissions or long motor cables.

Bulletin 511: NEMA contactor often used upstream of S-D4012 for safe isolation during maintenance.

S-D4006: 0.5 HP variant for very light loads like small exhaust fans or lab stirrers.

DriveTools SP Software: Legacy configuration tool for parameter backup and batch setup of multiple S-D4012 units.

Installation, Maintenance, and Full-Cycle Support

Installing the S-D4012 requires only basic wiring: connect L1/L2 to single-phase supply, T1/T2/T3 to the motor, and ensure proper grounding per NEC Article 430. For optimal performance, keep motor cables under 50 meters or add output reactors for longer runs. The drive’s intuitive keypad allows quick setup of acceleration/deceleration times, maximum frequency, and base speed—no software needed for standard applications.

Maintenance is minimal: periodically inspect for dust buildup (especially in fan-cooled NEMA 1 units) and verify terminal tightness. The S-D4012 displays clear fault codes (e.g., “OH” for overheat, “OL” for overload) with recovery instructions in the manual. Should replacement be necessary, the compact footprint (130 × 150 × 90 mm) ensures drop-in compatibility with most legacy panels. We supply tested and verified S-D4012 units, each inspected for DC bus stability, IGBT switching integrity, and communication functionality. All units include a 12-month warranty and are backed by technical support from engineers familiar with Reliance Electric’s legacy and Rockwell’s current ecosystem.

Contact us for a customized solution—whether you’re upgrading an old motor starter, designing a new OEM machine, or seeking energy savings in HVAC or material handling, the S-D4012 delivers proven reliability, simplicity, and efficiency from a trusted industrial brand.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: