Description

Application Scenarios

At a deepwater FPSO (Floating Production Storage and Offloading) vessel in the Gulf of Mexico, a legacy safety system struggled with slow response times during hydrocarbon leak events, risking escalation to fire. During a brownfield SIS upgrade, engineers selected the HIMA F8650X as the new safety controller due to its sub-50 ms logic scan and built-in redundancy. Within weeks of commissioning, the system successfully triggered a controlled shutdown within 32 ms of a simulated gas detection—well below the 100 ms target. The vessel’s safety team credited the F8650X’s deterministic performance and automatic fault bypass for preventing a potential Tier 1 process safety event, demonstrating how this module turns milliseconds into margins of safety.

Parameter

Main Parameters Value/Description

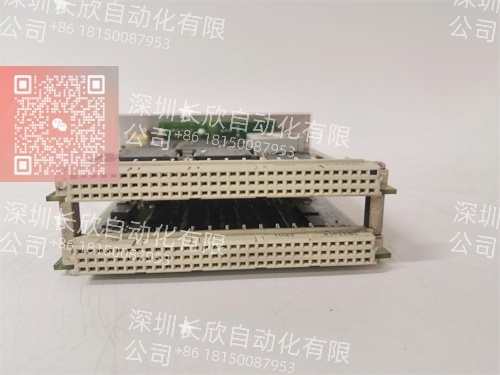

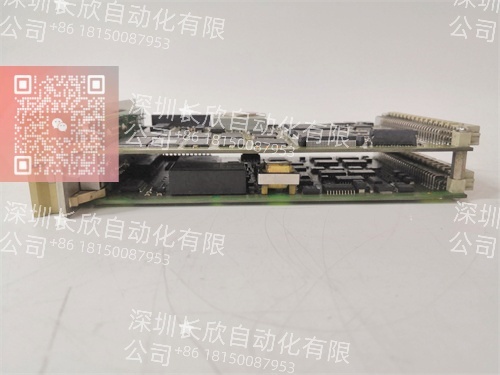

Product Model F8650X

Manufacturer HIMA Paul Hildebrandt GmbH + Co KG

Part Number 984865065

Product Category Central Processing Unit (CPU) Module for HIMax Safety Systems

Safety Integrity Level SIL3 per IEC 61508 / IEC 61511 (TÜV-certified system-level compliance)

Processor Architecture Dual-core lockstep or 1oo2D/2oo3 configurable redundant design

Logic Scan Time Typically <50 ms (scalable based on program size and I/O count) Memory Onboard non-volatile memory for safety program and event logs (no battery backup required) Communication Interfaces Integrated HIMA Safety Network (HSN) for peer-to-peer and I/O chassis linking Hot-Swap Support Yes – enables replacement without powering down the entire safety system Operating Temperature -20°C to +70°C (industrial grade, suitable for offshore and desert environments) Diagnostic Coverage >99.9% – includes memory ECC, clock monitoring, watchdog timers, and bus integrity checks

Certifications ATEX, IECEx, FM, CSA (for hazardous locations); TÜV Rheinland SIL3 certified

Power Consumption ~8.5 W (via HIMax backplane)

Redundancy Modes Supports 1oo1D, 1oo2D, and 2oo3 architectures for high-availability deployments

Technical Principles and Innovative Values

Innovation Point 1: The F8650X uses a patented “dual-decision” execution model where safety logic is computed in parallel across redundant cores, with real-time comparison to detect even transient faults—ensuring no dangerous undetected failure reaches the output stage.

Innovation Point 2: Integrated HIMA Safety Network (HSN) provides deterministic, time-synchronized communication between multiple F8650X units and remote I/O, eliminating reliance on standard Ethernet for critical data—critical in large-scale LNG trains.

Innovation Point 3: Full hot-swap capability with automatic state synchronization allows a failed CPU to be replaced in under 5 minutes while the redundant unit maintains full safety functionality—minimizing exposure during maintenance.

Innovation Point 4: Non-volatile program storage with error-correcting code (ECC) protects against cosmic-ray-induced bit flips in high-altitude or offshore installations using F8650X, a known risk in safety-critical electronics.

Innovation Point 5: Built-in cybersecurity features (secure boot, firmware signature verification) align with IEC 62443 standards, ensuring the F8650X remains tamper-proof in connected industrial environments.

Application Cases and Industry Value

In a Middle Eastern refinery undergoing a flare gas recovery project, regulators mandated a SIL3-certified SIS with zero single points of failure. The engineering team deployed a 2oo3 HIMax system centered on three HIMA F8650X modules. During a live test simulating a reactor overpressure, all three CPUs voted consistently, and the system isolated the feed within 41 ms. Post-project audit confirmed 100% diagnostic coverage and full compliance with ISA-84. The client reported that the F8650X’s seamless integration and pre-certified architecture shaved 14 weeks off the project schedule—turning regulatory compliance into a timeline advantage.

Another case involved a European hydrogen electrolysis plant where uptime directly impacted green fuel output. Using a 1oo2D F8650X configuration, the facility achieved 99.998% availability over two years. When one CPU failed due to a power surge, the system seamlessly switched to the healthy unit without triggering a shutdown. Operators only learned of the fault during the next shift change—proof that the F8650X delivers not just safety, but operational continuity.

Related Product Combination Solutions

F3236: 16-channel digital input module—feeds field signals (e.g., ESD buttons) into F8650X-based logic solvers.

F3330: Digital output module that executes shutdown commands from the F8650X to valves or motors.

HIMax CCM Chassis: Modular carrier that houses up to two F8650X CPUs for redundant configurations.

F6217: Analog input module for pressure/temperature safety variables processed by F8650X.

HIMA Safety Suite: Engineering software for programming, simulating, and certifying F8650X safety applications with automated SIL reports.

HSN Switch (e.g.,H4110): Dedicated safety network switch for multi-chassis F8650X expansions.

F8651X: I/O communication co-processor that offloads network tasks from the F8650X, boosting scan performance.

K-Bus Terminal System: Pre-engineered wiring solution that connects field devices to I/O modules linked to F8650X.

Installation, Maintenance, and Full-Cycle Support

Installing the HIMA F8650X begins with proper chassis grounding and adherence to separation rules between safety and basic process control wiring. Configuration is performed in HIMA Safety Suite: import logic diagrams, assign I/O tags, define redundancy behavior, and generate validation test cases—all with built-in SIL compliance checks. No jumpers or DIP switches are required, minimizing commissioning errors.

For maintenance, the F8650X provides comprehensive health status via front-panel LEDs and remote diagnostics over HSN. Routine tasks include reviewing event logs for “corrected memory errors” or “communication retries”—early indicators of latent issues. In redundant setups, failed units can be swapped live; the system auto-synchronizes the new module within seconds. Our global support team offers FAT/SAT assistance, cybersecurity hardening, and lifecycle management—including obsolescence planning for long-term projects. Every F8650X (984865065) we supply is factory-tested for full redundancy handshake, thermal stress resilience, and firmware integrity, and comes with a 12-month warranty, original calibration certificate, and rapid delivery from certified depots.

Contact us for a customized solution—whether you’re protecting a $ 10B LNG train or a modular hydrogen skid, we ensure your safety logic is not just compliant, but unshakably reliable.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: