Description

Description:

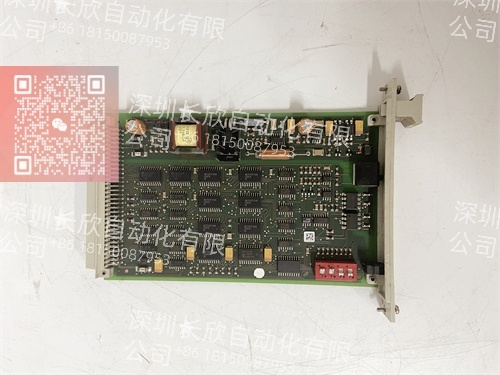

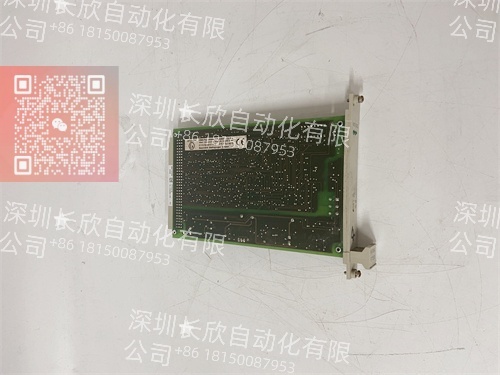

The HIMA F7553 is a high-integrity, 8-channel digital output module engineered for HIMA’s HIMax and HIQuad X safety instrumented systems (SIS). Designed to meet the most stringent functional safety requirements, it delivers fail-safe actuation with comprehensive self-diagnostics, per-channel monitoring, and full compliance with IEC 61508 SIL3 and IEC 61511 standards—making it a trusted component in emergency shutdown (ESD), fire & gas, and burner management systems worldwide.

Application Scenarios:

At a deepwater offshore production platform in the North Sea, an unplanned ESD activation caused a $ 2M/day revenue loss due to a latent fault in a legacy safety output card that lacked channel-level diagnostics. The root cause—a degraded relay coil—went undetected until failure. After migrating to the HIMA F7553. engineers gained real-time health status for each of the 8 output channels, including relay contact feedback and coil integrity checks. During a subsequent hydrotest, the system flagged a marginal channel 72 hours before it would have failed, allowing a planned replacement during maintenance window. Since deployment, the platform has achieved zero spurious trips over 24 months. The F7553 transformed safety from a passive barrier into an intelligent, predictive layer of operational resilience.

Main Parameters Value/Description

Product Model F7553

Manufacturer HIMA Paul Hildebrandt GmbH + Co KG

Product Category Safety Digital Output Module (SIL3)

Compatible Systems HIMax, HIQuad X

Number of Channels 8 independent, fail-safe output channels

Output Type Electromechanical safety relays (force-guided contacts per EN 50205)

Nominal Voltage 24 V DC (load side)

Switching Capacity 2 A per channel (resistive load)

Diagnostic Coverage >99% (per IEC 61508) via relay contact feedback and coil monitoring

Redundancy Support Fully compatible with 1oo2. 2oo3. and 2oo4 voting architectures

Hot-Swap Capability Yes – can be replaced without powering down the chassis

Certifications IEC 61508 SIL3. IEC 61511. ANSI/ISA 84.00.01. ATEX, FM, CSA

Operating Temperature -25°C to +70°C (with derating above 60°C)

Technical Principles and Innovative Values:

• Innovation Point 1: Per-Channel Relay Feedback Loop – Unlike standard safety outputs that only monitor coil voltage, the F7553 uses auxiliary contacts to verify actual relay armature position, detecting welded, stuck, or slow-operating contacts before they compromise safety function integrity.

• Innovation Point 2: Integrated Diagnostic Processor – Each F7553 contains a dedicated microcontroller that continuously runs built-in tests (BIT), reporting health status to the safety controller via redundant backplane buses—enabling predictive maintenance without external test equipment.

• Innovation Point 3: True Force-Guided Relay Design – All relays comply with EN 50205. ensuring that if a normally open (NO) contact welds shut, the corresponding normally closed (NC) feedback contact cannot close—guaranteeing detectable failure modes.

• Innovation Point 4: Seamless Redundancy Synchronization – In 2oo3 HIMax configurations, the F7553 automatically aligns output states across redundant modules during online replacement, preventing transient mismatches that could trigger nuisance trips.

Application Cases and Industry Value:

In a European ethylene cracker plant, the HIMA F7553 was deployed across 14 final element circuits controlling emergency isolation valves on high-pressure reactors. During a major turnaround, technicians used the module’s LED indicators and HIMA Safety Suite software to validate all 112 output channels (14 modules × 8) in under 30 minutes—compared to 4+ hours with legacy hardware requiring manual loop checks. Over three years, the plant recorded zero demand failures on protected loops and reduced proof-test intervals by 50% thanks to continuous diagnostics. “The F7553 doesn’t just meet SIL3—it makes SIL3 sustainable,” noted the site’s functional safety manager.

Related Product Combination Solutions:

• F7131: SIL3 digital input module for emergency pushbuttons and valve position feedback—paired with F7553 for complete ESD loop

• HIMax CEs: Central processing unit for HIMax system hosting F7553 modules

• F7951: Redundant power supply module for I/O chassis ensuring continuous operation

• HIQuad X CX: Controller backbone for HIQuad X architecture supporting F7553

• HIMA Safety Suite: Engineering tool for configuration, diagnostics, and SIL verification of F7553-based systems

• F7554: 4-channel high-current (5A) variant for solenoid or motor starter applications

• K-BUS Terminal Blocks: Certified field wiring interface for intrinsically safe or hazardous area connections

• F7231: Analog input module for pressure/temperature monitoring in integrated burner management systems

Installation, Maintenance, and Full-Cycle Support:

Installing the HIMA F7553 requires mounting it into a certified HIMax or HIQuad X I/O chassis, connecting shielded field wiring through approved terminal blocks, and verifying relay contact feedback loops during commissioning. Use HIMA Safety Suite to perform automated channel tests, validate voting logic, and generate compliance reports for regulatory audits. The module’s front-panel LEDs indicate power, OK status, and individual channel faults—enabling rapid visual troubleshooting.

Maintenance is simplified by continuous diagnostics: the system logs relay operation counts, detects abnormal switching times, and alerts operators to degrading components long before failure. Hot-swap capability allows replacement during live operation—critical for continuous-process industries. As an authorized HIMA partner, we supply only factory-new F7553 units with full traceability, pre-tested relay performance, and 24-month warranty. Our certified engineers provide SIL lifecycle support—from design and validation to decommissioning—ensuring your safety system remains compliant, reliable, and audit-ready.

Contact us for a customized solution—whether you’re upgrading an ESD system, designing a new SIL3 facility, or implementing predictive safety diagnostics to maximize uptime without compromising protection.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: