Description

Application Scenarios:

In a decades-old but still vital refinery, the primary Emergency Shutdown (ESD) system is built on a TRICONEX V9 platform. The central TMR processor (TRICONEX 3008) is housed in the main control room, but the safety-critical field devices—like pressure transmitters and shutdown valves—are spread across distant process units. The TRICONEX 9853-2-9832 module acts as a vital communications bridge in this architecture. Installed in a remote I/O chassis near the field devices, it gathers diagnostic and status data from local digital and analog input modules. It then packages this data and transmits it over a high-integrity, fault-tolerant network back to the main processor. Conversely, it receives voting results and commands from the main processor and distributes them to the local output modules that actuate the safety valves. If this communication link fails, the remote I/O rack becomes blind. The 9853-2-9832’s robust, TMR-aligned design ensures this critical data path remains available, maintaining the integrity of the entire safety loop spread across the facility.

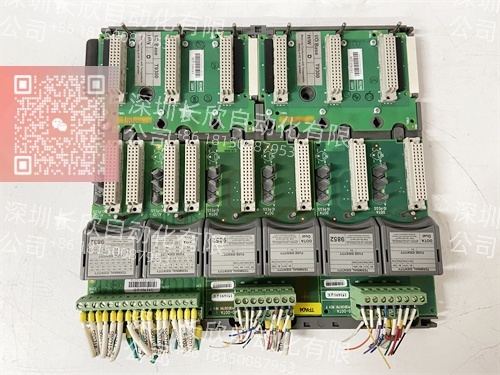

Parameter:

Technical Principles and Innovative Values:

Innovation Point 1: Distributed Fault-Tolerant I/O Architecture. The TRICONEX 9853-2-9832 was a key enabler of distributing the Tricon’s I/O away from the main processor chassis. It implemented the same rigorous, triple-redundant communication philosophy as the central controller. Data to and from the I/O modules was managed and transmitted across three separate channels within the module. This meant a single communication fault would be voted out, preventing a corrupted signal from causing a nuisance trip or, more critically, a failure to act. This distributed yet secure architecture provided significant wiring savings and installation flexibility while maintaining the system’s overall Safety Integrity Level (SIL 3).

Innovation Point 2: Deterministic Data Exchange for Safety-Critical Timing. In safety systems, it’s not enough for data to be accurate; it must also be timely. The TRICONEX 9853-2-9832 managed I/O scanning and communication with a deterministic schedule. It guaranteed that field input data was sampled and reported to the main processor within a known, fixed time window, and that output commands were delivered to the field with predictable latency. This deterministic behavior was crucial for meeting the performance requirements (e.g., Process Safety Time) of Safety Instrumented Functions (SIFs), ensuring the safety logic could act within its allotted time frame.

Innovation Point 3: Seamless Integration and Cohesive Diagnostics. The module was designed as an integral, transparent part of the Tricon V9 ecosystem. To the system engineer programming in TriStation 1131. the I/O points connected through a 9853-2-9832 in a remote chassis appeared no differently than those in the main chassis. Furthermore, the module’s health was fully integrated into the system’s comprehensive diagnostic suite. Faults in the communication link or within the interface itself were reported clearly to the engineering workstation, allowing for proactive maintenance and swift identification of issues, which is paramount for maintaining system availability and safety.

Application Cases and Industry Value:

Case Study: Pipeline Compressor Station Safety System Lifecycle Extension

A major natural gas pipeline operator had several remote compressor stations protected by legacy Tricon V9 systems. A critical remote I/O chassis, responsible for monitoring turbine vibration and temperature, began reporting intermittent faults. Diagnostics pointed to the TRICONEX 9853-2-9832 communication interface module as the failing component. Replacing the entire safety system was cost-prohibitive and would require a lengthy station shutdown. Sourcing a certified, tested TRICONEX 9853-2-9832 spare was the optimal solution. During a planned maintenance outage, technicians performed a hot-swap replacement of the module. The new module was recognized by the system, and its configuration was automatically loaded. The station was returned to service quickly, with the safety system’s integrity fully restored at a fraction of the cost of a full upgrade. This case underscores the value of supporting legacy components to ensure the continued safe and economical operation of critical infrastructure.

Related Product Combination Solutions:

The TRICONEX 9853-2-9832 is a component within a larger, integrated safety system. Key related components include:

TRICONEX 3008 Main Processor: The central TMR brain of the V9 system that the 9853-2-9832 ultimately communicates with.

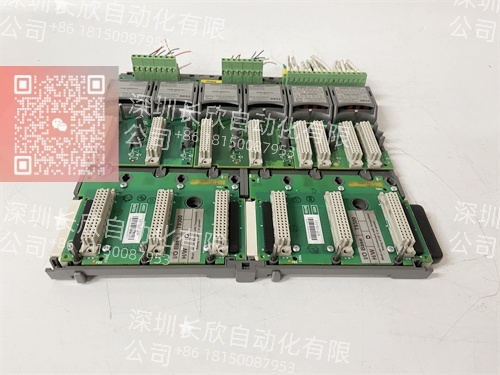

TRICONEX I/O Chassis (e.g., 4119A): The physical rack that houses the 9853-2-9832 and other I/O modules.

TRICONEX Legacy I/O Modules: Digital and analog modules (e.g., 980x, 981x, 983x series) that plug into the same chassis and are managed by the 9853-2-9832. Examples include TRICONEX 9802-610K (Digital Input) or TRICONEX 9832-010 modules.

TRICONEX Power Supply (for I/O Chassis): A dedicated, redundant power supply unit (e.g., specific to the 4119A chassis) that provides clean power to the 9853-2-9832 and its associated I/O cards.

TRICONEX Communication Cables/Trunks: Specialized, shielded cable assemblies used to connect the remote chassis containing the 9853-2-9832 back to the main processor chassis.

TRICONEX TRISTATION 1131 Software: The configuration and programming environment where the hardware layout, including the 9853-2-9832 and all connected I/O, is defined and the application logic is written.

Installation, Maintenance, and Full-Cycle Support:

Installation and replacement of the TRICONEX 9853-2-9832 must be performed by personnel trained on Triconex systems, following strict lock-out/tag-out and hot-swap procedures where applicable. The module is keyed for a specific slot in its I/O chassis. During replacement, it is critical to first place the chassis or module in a maintenance mode using the TriStation software. After the new 9853-2-9832 is inserted, the system will typically recognize it, perform integrity checks, and load the necessary firmware and configuration.

Routine maintenance involves monitoring the module’s status LEDs and reviewing system diagnostics via the engineering workstation. The hot-swap capability is a key feature, allowing a faulty module to be replaced without taking the entire safety system offline. Given the age of systems using this module, proactive sparing is a critical maintenance strategy.

We specialize in supporting legacy safety systems. We supply fully tested and certified TRICONEX 9853-2-9832 modules. Each unit undergoes functional testing to verify communication and I/O handling capabilities. We understand the complexities and critical nature of these legacy components and provide the necessary compatibility verification and documentation. Our expertise helps you extend the operational life of your safety assets reliably and cost-effectively.

Contact us for certified legacy Triconex components and the expert support needed to keep your critical safety systems fully functional and compliant.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: