Description

Description

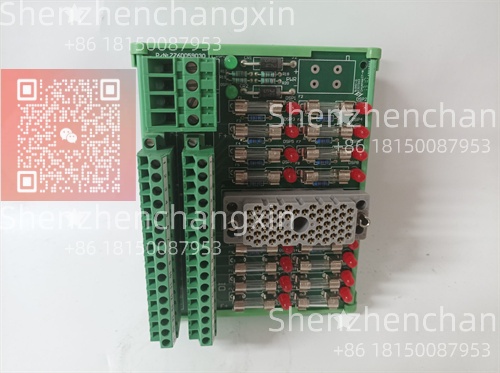

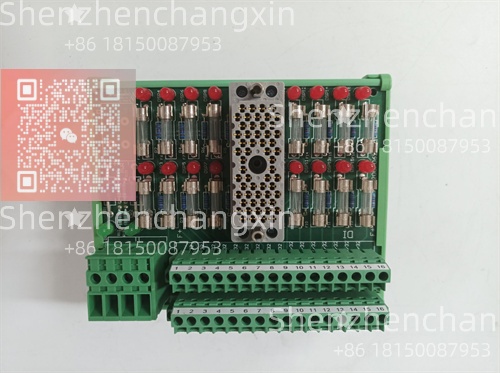

The TRICONEX 9563-810 is a high-integrity communication module designed for Schneider Electric’s Tricon™ v10 and v11 Safety Instrumented Systems (SIS). As part of the Triple-Modular Redundant (TMR) architecture, it provides secure, deterministic, and fault-tolerant Ethernet connectivity between the Tricon main processors and external supervisory systems—such as DCS, HMI, historians, or engineering workstations—without compromising safety integrity. Supporting both copper (RJ45) and fiber-optic interfaces, the 9563-810 enables safe data exchange while maintaining strict separation between safety and non-safety networks.

Engineered for continuous operation in hazardous and mission-critical environments, this module is a cornerstone of modern functional safety infrastructure in refineries, power plants, and chemical facilities worldwide.

Application Scenarios

At a major LNG export terminal in Australia, operators needed to integrate their Tricon-based emergency shutdown (ESD) system with a new Honeywell Experion DCS for unified monitoring—but without violating IEC 61511 zoning rules. By deploying dual TRICONEX 9563-810 modules in a redundant configuration, they established a unidirectional, read-only data path from the SIS to the DCS using Modbus TCP over fiber. The solution passed rigorous cybersecurity audits (IEC 62443 Level 3) and eliminated manual data logging. During a cryogenic pump trip event six months later, real-time ESD status appeared in the control room within 200 ms—enabling faster operator response. This deployment proves how the 9563-810 bridges safety and operations securely, reliably, and compliantly.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: True TMR Network Architecture – Unlike single-channel gateways, the 9563-810 replicates all network traffic across three physically isolated paths inside the module, with hardware-level voting to detect and mask faults—ensuring no corrupted data escapes the SIS.

Innovation Point 2: Safety-Enforced Data Diode Behavior – By design, the module only allows outbound status and diagnostic data (e.g., trip flags, I/O states), preventing any external command or malware from entering the safety controllers—meeting ISA/IEC 62443 “zone/conduit” requirements.

Innovation Point 3: Deterministic Latency Under Load – Even during 100% network utilization, data transmission jitter remains <1 ms due to dedicated TMR processing engines—critical for time-stamped event analysis.

Innovation Point 4: Zero Configuration on Safety Side – Once installed, the 9563-810 requires no IP setup in the Tricon application logic; all addressing is handled externally, reducing engineering errors and simplifying validation.

Application Cases and Industry Value

A European ethylene cracker upgraded its 20-year-old Tricon system to v11 and needed secure historian integration for PHA (Process Hazard Analysis) compliance. Using two TRICONEX 9563-810 modules, they streamed 1.200+ safety tag values to an OSIsoft PI System via a hardened demilitarized zone (DMZ). Over two years, the system recorded zero network-related safety interruptions—even during ransomware attempts on the corporate network. Auditors highlighted the 9563-810’s “air-gap-like security without physical isolation” as a best practice.

In a U.S. nuclear auxiliary feedwater system, the 9563-810 enabled remote NRC-compliant monitoring of SIS health during refueling outages. Its IEEE 1588 support synchronized event logs across multiple Tricon racks to ±1 µs—proving invaluable during root cause analysis of a spurious valve closure.

Related Product Combination Solutions

TRICONEX 3701E: Main Tricon v11 chassis that hosts the 9563-810 communication module.

TRICONEX 3503E: TMR digital input module often used in ESD circuits monitored via 9563-810.

TRICONEX 3603E: TMR analog output module for final element control (e.g., solenoid drivers).

Schneider Foxboro I/A: DCS platform that integrates 9563-810 data via Modbus TCP for alarm management.

HIMA H51q: Alternative SIS where similar secure gateways are required—useful for hybrid plant comparisons.

GE 8502-BI-DP: In combined-cycle plants using both Mark VIe and Tricon—data correlation via 9563-810 enhances diagnostics.

BENTLY NEVADA 3500: Vibration protection system whose alarms can be cross-checked against Tricon trip logs via 9563-810 data.

Triconex Enhanced Diagnostic Monitor(EDM): Software that visualizes 9563-810 network health and traffic statistics.

Installation, Maintenance, and Full-Cycle Support

Installing the TRICONEX 9563-810 involves inserting it into a designated slot in a powered Tricon chassis—no tools required. External cabling connects to redundant network switches using shielded Ethernet or fiber. IP addressing, VLANs, and firewall rules are configured externally; the SIS side remains untouched, preserving validation integrity.

Maintenance is minimal: front-panel LEDs indicate link status, TMR sync, and fault conditions. The module supports hot-swap—removal or insertion does not trigger a controller reset. All communication events and internal diagnostics are logged and accessible via Triconex EDM or third-party SIEM tools.

We supply only genuine TRICONEX 9563-810 units—new surplus or factory-refurbished—with full functional testing on live Tricon v11 systems, including TMR sync verification, failover simulation, and cybersecurity hardening checks. Each unit includes original firmware and complies with Schneider’s lifecycle management policy. Backed by a 12-month warranty and access to ex-Triconex engineers, we ensure your safety network stays secure, certified, and operational.

Contact us for a customized solution—whether you’re integrating a new SIS or modernizing legacy safety infrastructure, the TRICONEX 9563-810 delivers uncompromised security, reliability, and compliance where failure is not an option.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: