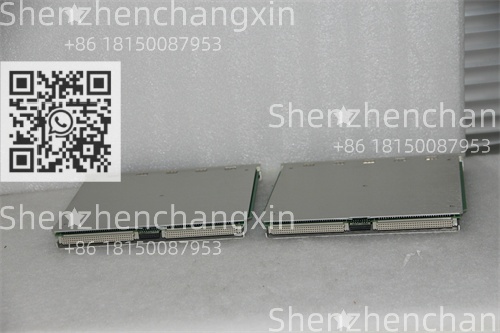

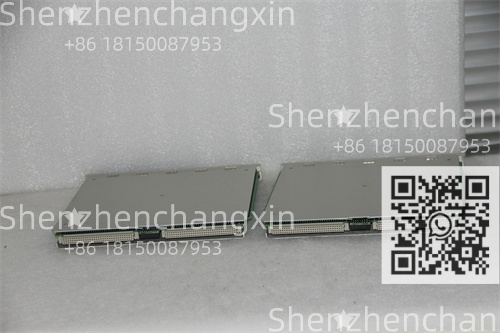

Description

Application Scenarios

At a North Sea offshore platform, a main gas compression train suffered repeated bearing failures due to undetected misalignment. The legacy monitoring system used discrete transmitters with slow response times. After upgrading to a BENTLY 3500/40M-based architecture, engineers connected four dual-probe sets (radial X/Y + thrust) directly to a single module. Within weeks, the system flagged a subtle 12 µm increase in axial position during startup—a precursor to thrust bearing wear. The platform triggered a controlled shutdown before catastrophic failure, avoiding an estimated $ 8M in equipment damage and 10 days of lost production. This incident proved that the BENTLY 3500/40M isn’t just a data collector—it’s a frontline defense against unplanned downtime in mission-critical rotating equipment.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Integrated Proximitor Power & Conditioning – Unlike generic AI modules, the BENTLY 3500/40M generates the precise -24 VDC bias required by eddy-current probes and demodulates the AC carrier signal into a proportional DC voltage—eliminating external conditioners and reducing noise susceptibility.

Innovation Point 2: Dual Independent Trip Relays – Each channel can drive two separate safety circuits (e.g., one to ESD, one to DCS), satisfying redundancy requirements in SIL 2 and API 670 systems without additional hardware.

Innovation Point 3: True Gap Voltage Monitoring – The BENTLY 3500/40M continuously measures the raw DC gap voltage (not just filtered vibration), enabling detection of probe fouling, mounting looseness, or target surface defects—critical for predictive maintenance.

Innovation Point 4: Seamless System 1 Integration – When paired with Bently Nevada System 1 software, the BENTLY 3500/40M enables automated trending, spectral analysis, and alarm rationalization—turning raw data into actionable machinery health insights.

Application Cases and Industry Value

In a combined-cycle power plant in Texas, three BENTLY 3500/40M modules monitor a 250 MW steam turbine-generator set. During a routine startup, the axial position channel on one module triggered a “Danger” alarm at 0.8 mm—well below the mechanical trip point but above baseline. Vibration analysts reviewed historical trends and identified progressive thrust pad wear. The unit was taken offline during a scheduled outage, avoiding a potential rotor seizure. Plant engineers credited the BENTLY 3500/40M’s high-resolution gap monitoring and fast relay response for preventing a multi-week forced outage.

Similarly, in a LNG export terminal, BENTLY 3500/40M modules provide zero-speed detection for emergency lube oil pumps. Using special speed probes, the module confirms pump rotation within 200 ms of start command—meeting strict NFPA 850 requirements for fire-safe auxiliary systems. Operators report 99.99% reliability over five years, proving the BENTLY 3500/40M excels in both continuous monitoring and safety-critical interlock roles.

Related Product Combination Solutions

BENTLY 3500/15: Power supply module—provides redundant ±24 VDC and +5 VDC for BENTLY 3500/40M operation.

BENTLY 3500/32: 4-channel relay module—expands alarm output capacity when BENTLY 3500/40M relays are insufficient.

BENTLY 3500/22: Temperature monitor—complements BENTLY 3500/40M for full bearing health coverage (vibration + temp).

BENTLY 3300 XL 8mm Probe: Standard eddy-current sensor—optimized for use with BENTLY 3500/40M in turbomachinery.

BENTLY 3500/42M: Enhanced version with 8 channels—ideal for large compressors requiring dense I/O.

BENTLY 3500/50: Overspeed protection module—pairs with BENTLY 3500/40M for comprehensive turbine safety.

BENTLY 3500/92: Communications gateway—enables Modbus TCP or Ethernet/IP access to BENTLY 3500/40M data.

BENTLY System 1: Asset performance management software—unlocks advanced analytics for BENTLY 3500/40M data streams.

Installation, Maintenance, and Full-Cycle Support

Installing the BENTLY 3500/40M requires insertion into a powered 3500 chassis, followed by configuration via the Rack Configuration Software (RCS). Probe wiring connects directly to front-panel BNC or screw terminals, while relay outputs link to safety shutdown systems. Calibration is factory-performed; field verification uses the built-in test points for gap voltage simulation.

Maintenance is minimal: the module features self-diagnostics for open/short circuits, power faults, and internal errors—displayed via front-panel LEDs and System 1. Hot-swap capability allows replacement without powering down the entire rack. We rigorously test every BENTLY 3500/40M for signal accuracy, relay timing, and thermal stability before shipment. Our support includes configuration templates, API 670 compliance checklists, and 24/7 technical assistance for critical outages. All units carry a 24-month warranty and full calibration certificates traceable to NIST standards.

Contact us for a customized solution—whether you’re commissioning a new compressor train, modernizing legacy protection systems, or building a global spare parts strategy, the BENTLY 3500/40M delivers the precision, reliability, and compliance your rotating assets demand.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: