Description

Application Scenarios

In a large offshore oil and gas platform, the Fire & Gas (F&G) and Emergency Shutdown (ESD) system must process thousands of sensor inputs and execute safety logic with zero tolerance for failure. The Tricon safety controller, the brain of this system, resides in a central control room, but the field inputs and shutdown valves are spread across the facility. The TRICONEX T8480C module is the vital nervous system within each controller chassis. It takes the processed safety commands from the triple-redundant Main Processors and reliably broadcasts them over the robust Triplex I/O network to remote I/O packs controlling critical valves. Simultaneously, it aggregates field sensor data from those same remote locations and delivers it to the processors for evaluation. A fault in this communication path could blind the safety system. The T8480C’s triple-modular redundant design ensures that even if one of its internal channels fails, the other two maintain seamless, error-free communication, guaranteeing that a gas leak detection signal is never lost and a shutdown command always reaches its destination.

Parameter

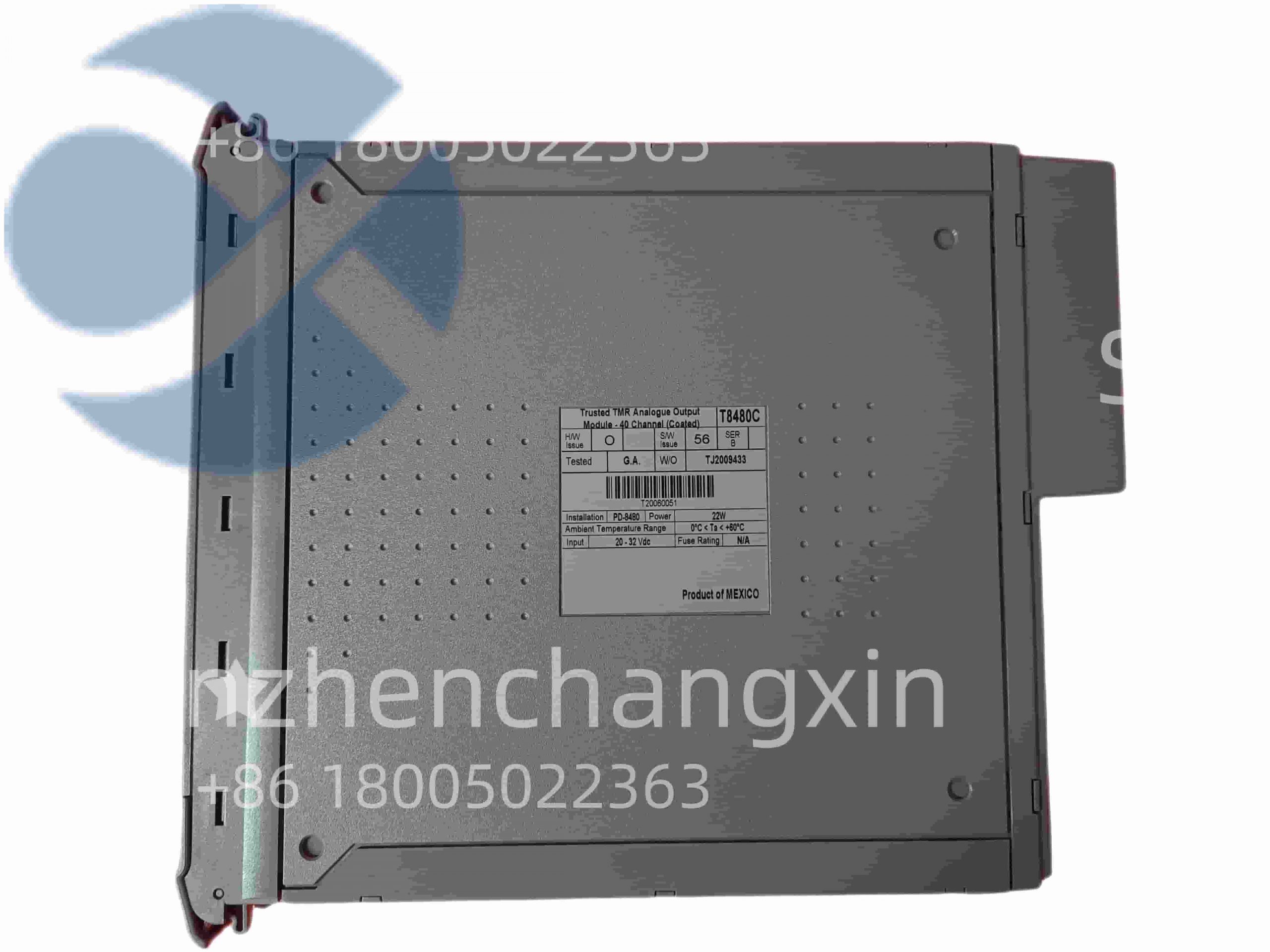

Annotation: The T8480C is a Triplexmodule, meaning it contains three independent communication channels operating in sync. Its core value is maintaining the integrity of the critical data highway between the safety controller’s brain (CPU) and its limbs (I/O) in a fault-tolerant architecture.

Technical Principles and Innovative Values

The TRICONEX T8480C is engineered for ultimate reliability, employing a parallel, fault-masking architecture rather than a simple single-channel design.

Innovation Point 1: True Triple-Modular Redundant (TMR) Communication Paths. The module contains three isolated communication subsystems operating in parallel. Each leg communicates independently with its corresponding processor in the TMR triad and the remote I/O. A hardware voter in the receiving module (I/O or processor) compares the three data streams. If one leg deviates due to a fault, it is out-voted by the two correct legs, and the system continues without interruption, data corruption, or latency. This provides seamless fault tolerance unavailable in duplex systems.

Innovation Point 2: Synchronized, Deterministic Data Exchange. The T8480C manages a deterministic, high-speed network. It ensures that data from hundreds of I/O points is collected and delivered to the Main Processors in a perfectly synchronized, predictable scan cycle. This deterministic behavior is critical for complex sequential safety logic and ensures that all parts of the safety system are operating on the same, timely data set.

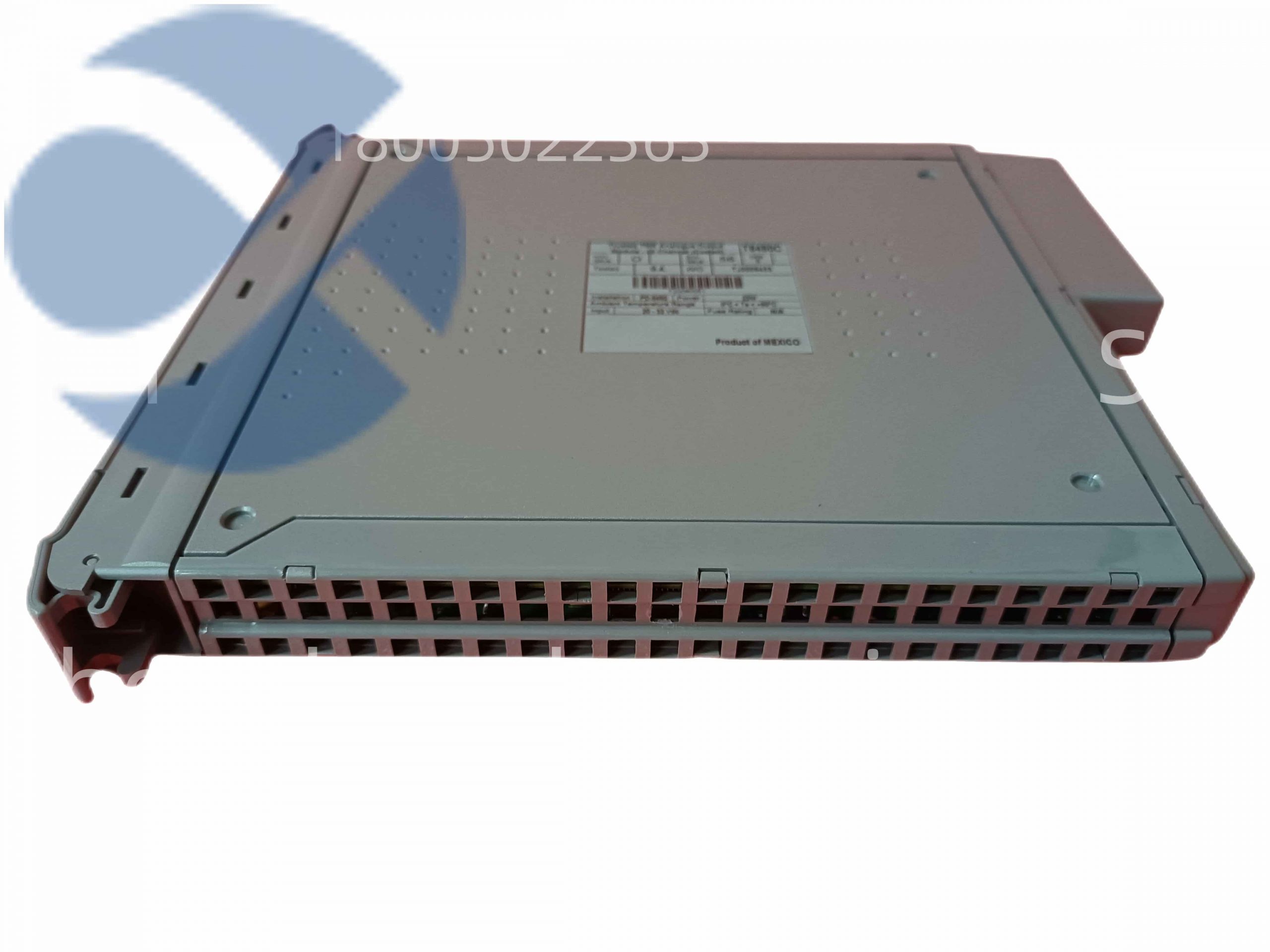

Innovation Point 3: Comprehensive Online Diagnostics and Hot Replacement. The module performs constant self-checks on its internal circuitry and the integrity of the Triplex I/O bus. Faults are immediately reported to the diagnostic processor and the control software. Furthermore, the T8480C is designed for online hot replacement in a properly configured system. A faulty module can be identified via its LEDs, removed, and replaced without requiring a shutdown of the Tricon controller or the safety functions it oversees, maximizing system availability.

Application Cases and Industry Value

Case Study: Preventing a Catastrophic Turbine Overspeed in a Power Plant

A combined-cycle power plant relied on a Tricon TMR system as its primary Turbine Control and Protection system. The TRICONEX T8480C modules were the communication backbone in the controller chassis, handling data from vibration probes, temperature sensors, and valve positioners. During a routine online diagnostic scan, the system flagged a “disagreement” fault on one channel of a T8480C module. The plant’s procedure, enabled by the hot-swap capability, allowed engineers to safely replace the module during normal operation. Post-analysis showed a marginal component on one of the three legs was causing intermittent errors. Because of the TMR architecture managed by the T8480C, the two healthy legs had masked this fault completely—the turbine control never missed a beat. The early detection and graceful degradation prevented what could have been an unplanned turbine trip or, worse, a control system failure leading to an overspeed event, protecting tens of millions of dollars in equipment and ensuring continuous power generation.

Case Study: Ensuring Uninterrupted Safety in a Petrochemical Complex

A major ethylene cracker used a distributed Tricon system for its burner management and furnace safety. A communication failure between the central controller and the remote I/O managing the pilot igniters and flame scanners could lead to an unsafe condition. The use of T8480C modules ensured this link was inherently fault-tolerant. During a plant-wide stress test simulating multiple failures, engineers manually introduced a fault on the Triplex I/O bus. The T8480C modules in the affected chassis immediately reported the cable fault but, crucially, continued to pass valid I/O data using the two remaining healthy communication paths, allowing the safety system to remain fully functional throughout the repair. This demonstrated the “no single point of failure” design, giving operations immense confidence in the plant’s safety integrity.

Related Product Combination Solutions

TRICONEX 3008N Main Processor: The central TMR processor module for the Tricon v9 system. The T8480C module resides in the same chassis and is the dedicated communication conduit between this processor and the remote I/O.

TRICONEX T8461 or T8110B: These are examples of other critical modules (like a communication or bus interface module) that would be installed in the same chassis as the T8480C, forming the complete controller.

TRICONEX 4351B Analog Input Module: A representative remote I/O module. The T8480C communicates with racks of these modules over the Triplex I/O bus, reading their analog sensor data.

TRICONEX 3503E Digital Output Module: A remote I/O module that executes commands. The T8480C transmits output commands from the Main Processor to modules like this to activate shutdown valves or other final elements.

TRICONEX T8460C I/O Comm Mod for Legacy: Often used in conjunction with or as a predecessor/related module to the T8480C in different chassis configurations or system versions.

TRICONEX T9802 Advanced Communication Module: Provides external network connectivity (e.g., to a DCS or HMI). While the T8480C handles internal I/O traffic, a module like the T9802 handles external system communication.

TRICONEX Chassis (e.g., for v10 system): The physical rack that provides power, the backplane, and slots for the T8480C, Main Processors, and other system modules.

Installation, Maintenance, and Full-Cycle Support

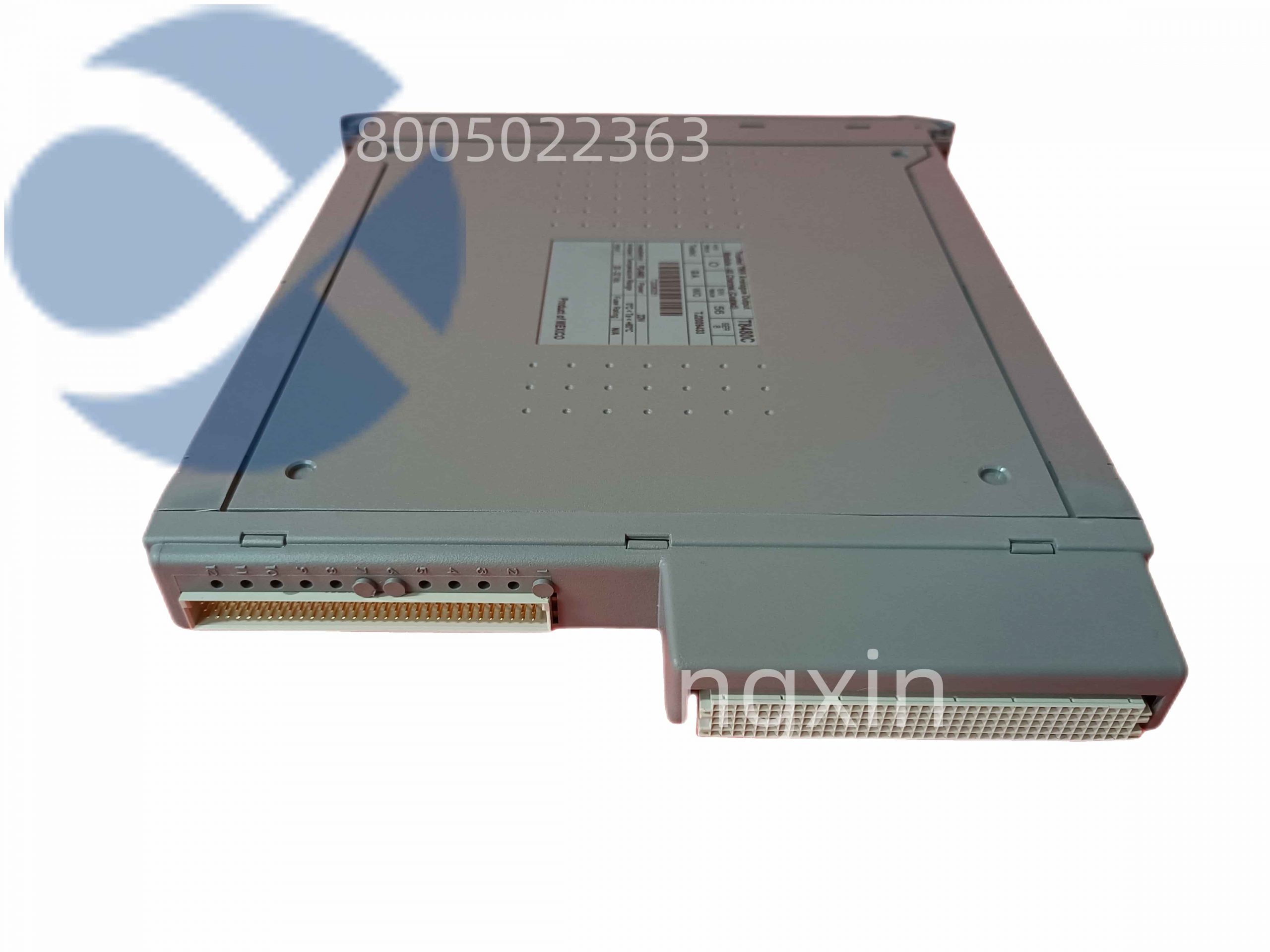

Installation of the TRICONEX T8480C is a precise procedure within a Tricon chassis. It must be inserted into its designated slot according to the chassis configuration diagram. The most critical step is ensuring the Triplex I/O bus cables are securely connected to its front-face ports, as these are the lifelines to the remote I/O. Pre-installation involves static discharge precautions and verification of the chassis power. Configuration is inherently tied to the Tricon system; the module is automatically recognized by the Tricon Diagnostics and Control Software upon insertion into a powered chassis with a valid configuration.

Maintenance is heavily reliant on the module’s advanced diagnostics. Engineers should regularly monitor the module’s status via the Tricon software and its LED indicators (typically showing OK, Active, and fault status for each of the three channels). The system is designed to identify a failing T8480C before it causes a process disruption. The key maintenance advantage is hot-swap capability. Following strict procedures, a faulty module can be identified, extracted, and replaced with a new one without taking the safety controller offline—a crucial feature for continuous processes. Our full-cycle support is designed for critical systems. We provide access to detailed technical manuals, compatibility matrices, and firmware documentation. We supply fully tested, genuine T8480C modules and offer expert troubleshooting support to help interpret diagnostic codes and plan effective maintenance interventions, ensuring the long-term reliability and certification of your safety instrumented system.

For the critical communication links in your highest-availability safety systems, trust proven TMR technology. Contact us for technical specifications, compatibility verification, and reliable sourcing for the TRICONEX T8480C and related Tricon system components.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email:

.jpg)