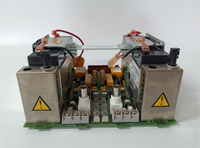

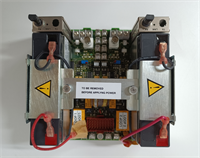

Description

Description

The ABB NTCF22 is a PROFIBUS DP (Decentralized Periphery) communication module designed to connect ABB AC 800M local I/O stations—such as those built on TB840 or TB850 baseplates—to a central PROFIBUS network. It functions as a high-performance fieldbus coupler, enabling remote I/O racks to communicate with PLCs or DCS controllers from ABB, Siemens, Rockwell, or other PROFIBUS-compliant systems.

As a key enabler of distributed control architectures, the ABB NTCF22 reduces cabling complexity, lowers installation costs, and enhances system modularity—especially in large-scale or geographically dispersed industrial facilities.

Application Scenarios

At an automotive assembly plant in Germany, engineers needed to integrate dozens of motor control centers (MCCs) spread across 500 meters of production floor into a central ABB 800xA system. Running individual signal wires back to the main control room was cost-prohibitive and inflexible. Instead, they deployed ABB NTCF22 modules at each MCC, connecting local DI/DO/AI modules via short backplane links and linking everything to a single PROFIBUS trunk. The ABB NTCF22 delivered real-time I/O updates at 12 Mbps with deterministic cycle times under 5 ms. Maintenance teams now troubleshoot faults remotely using PROFIBUS diagnostics, and new stations are added in hours—not weeks. In this setting, the ABB NTCF22 transformed a wiring nightmare into a scalable, future-ready architecture.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: True Redundant Power with Hot-Swap Capability

The ABB NTCF22 features dual independent 24 V DC inputs. If one supply fails, the module continues operating without interruption—a critical feature for continuous processes like chemical reactors or water treatment.

Innovation Point 2: Plug-and-Play Addressing with Physical DIP Switches

Unlike software-dependent modules, the ABB NTCF22 uses hardware DIP switches for PROFIBUS node addressing, eliminating configuration errors during replacement and enabling instant “blind swaps” in emergency scenarios.

Innovation Point 3: Full DP-V1 Support for Advanced Diagnostics

Beyond basic I/O exchange, the ABB NTCF22 supports acyclic DP-V1 services, allowing master systems to read module temperature, input status logs, and fault counters—enabling predictive maintenance in 800xA or third-party SCADA platforms.

Innovation Point 4: Backplane Bandwidth Optimization

Internally, the ABB NTCF22 uses a high-speed parallel bus to scan all connected I/O modules in <1 ms, ensuring minimal latency even with full racks of DI880 or AO810 cards. Application Cases and Industry Value In a pulp and paper mill in Finland, the ABB NTCF22 was deployed to modernize dryer section controls. Previously, over 1.200 signals ran through multi-core cables vulnerable to moisture and abrasion. By installing NTCF22-based remote I/O cabinets near each dryer cylinder, the plant reduced cable length by 85%, cut installation labor by 60%, and improved signal reliability. During a recent audit, the mill reported zero communication-related downtime over 18 months—validating the ABB NTCF22’s ruggedness in high-humidity, high-EMI conditions. Another success story comes from a food & beverage bottling line in Mexico, where rapid changeovers demanded flexible I/O zoning. Using ABB NTCF22 modules on mobile skids, engineers reconfigure entire production cells by simply plugging skids into pre-wired PROFIBUS drop points—reducing line conversion time from 8 hours to 45 minutes. Related Product Combination Solutions ABB TB842V1: I/O baseplate with screw terminals, ideal for pairing with NTCF22 ABB DI880 (3BHB030845R0004): 16-channel digital input module commonly used in NTCF22 stations ABB DO810: Digital output module for solenoid and contactor control ABB CI854A: Alternative PROFIBUS module with enhanced redundancy for CPU-level integration ABB TK801: Fiber-optic extender for long-distance NTCF22 PROFIBUS segments (>1 km)

Siemens IM 153-2: Compatible PROFIBUS interface for mixed-vendor environments

ABB 800xA System 800: Full DCS platform that auto-detects and configures NTCF22 stations

ABB PM864A (3BHB010662R0250): AC 800M CPU that can act as PROFIBUS master or coexist with external masters

These components form a versatile, interoperable ecosystem for both greenfield and hybrid automation projects.

Installation, Maintenance, and Full-Cycle Support

Installing the ABB NTCF22 begins with secure DIN-rail mounting and connection to a compatible I/O baseplate (e.g., TB842). Wire the PROFIBUS cable using shielded twisted pair (A/B lines), terminate with 220 Ω resistors at both ends, and set the node address via the front DIP switch bank. Power connections support redundant feeds—connect both if available for maximum availability.

During commissioning, verify link status via the BF (Bus Fault) and SF (System Fault) LEDs. Use a PROFIBUS tester or engineering tool (e.g., Control Builder M or Step 7) to confirm I/O mapping and cyclic update rates. The module requires no firmware updates or calibration.

For maintenance, the ABB NTCF22’s robust design ensures years of trouble-free service. In case of failure, replacement takes under 5 minutes: power down (if non-redundant), unplug, insert new unit, and restore power—the master automatically re-identifies it. All units we supply undergo full functional testing, including PROFIBUS protocol conformance, thermal cycling, and ESD immunity checks.

We provide detailed wiring diagrams, GSD files for master configuration, and lifecycle support—including cross-references to newer alternatives like the NTCL11 (for PROFINET) when migration is planned.

Contact us for a customized solution—whether you’re expanding an existing PROFIBUS network, integrating third-party equipment, or sustaining a mission-critical legacy system. With global inventory and deep ABB integration expertise, we keep your fieldbus running, reliably and efficiently.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: