Description

Application Scenarios

In a high-speed beverage bottling line, the synchronization of a rotary filler carousel with an incoming conveyor is critical. Any misalignment results in spillage, jams, and costly production stoppages. The ELAU MC-41110400 servo drive is the key to this precise synchronization. It directly controls the torque and position of the filler carousel’s main servo motor. Running PacDrive automation software directly on its processor, the MC-41110400 executes cam profiles that perfectly match the conveyor speed, while simultaneously controlling the individual filler valves. Its integrated Safe Torque Off (STO) safety function ensures maintenance can be performed safely. The MC-41110400 solves the pain points of mechanical complexity, lack of flexibility, and unreliable synchronization, enabling faster changeovers, higher throughput, and significant reductions in waste.

Parameter

Technical Principles and Innovative Values

The ELAU MC-41110400 represents a convergence of drive and logic control, engineered to simplify machine architecture and enhance performance.

Innovation Point 1: Integrated Motion & Logic Control. Unlike traditional architectures requiring separate PLCs and drives, the MC-41110400 combines a powerful multi-axis servo controller and a PLC-grade logic engine in one device. It can execute complex IEC 61131-3 logic, motion control programs, and high-performance servo loops simultaneously. This “all-in-one” design eliminates communication delays between separate components, enabling faster machine cycles, simplifies cabinet layout, and reduces the total number of system components, boosting reliability.

Innovation Point 2: High-Performance, Deterministic Networking. The drive features integrated EtherCAT and SERCOS interfaces. EtherCAT provides a highly deterministic, low-latency network for synchronized multi-axis control, allowing dozens of MC-41110400 drives and I/O modules to act as a single, tightly coordinated system. This enables advanced applications like electronic gearing, camming, and flying saws with sub-millisecond precision across the entire machine.

Innovation Point 3: Built-in Safety and Servo Performance. The MC-41110400 incorporates Safe Torque Off (STO) as a standard safety function. This allows for a safe, powerless state of the motor without disconnecting main power, simplifying safety circuit design and compliance with machinery directives. Furthermore, its advanced control algorithms support high-resolution feedback systems, enabling extremely precise positioning and smooth motion even at very low speeds, which is critical for applications like direct-drive packaging machines.

Application Cases and Industry Value

Case Study: Robotics-Integrated Primary Packaging Machine

A machine builder (OEM) specializing in primary packaging for cosmetics needed to develop a new machine that integrated a 6-axis articulated robot for product placement with a high-speed intermittent motion cartoner. The challenge was achieving perfect synchronization between the continuous path of the robot and the indexed motion of the carton conveyor.

Process & Improvement: The OEM designed the system around a central ELAU MC-41110400 drive as the master controller. This drive controlled the main cartoner servo and, via EtherCAT, several auxiliary axes. The robot controller was seamlessly integrated as a slave device on the same EtherCAT network managed by the MC-41110400. Using the IEC 61131-3 programming in the PacDrive software, engineers created a virtual master axis in the MC-41110400. to which both the robot and all servo axes were electronically geared. The result was flawless, jitter-free synchronization. The machine’s commissioning time was reduced by 30% due to the unified programming environment. The end-user reported a 20% increase in packaging speed and a near-elimination of product misalignment faults, attributing the gains to the precise, centralized control enabled by the ELAU MC-41110400 architecture.

Related Product Combination Solutions

The ELAU MC-41110400 functions as the centerpiece of a complete PacDrive motion control solution.

ELAU MC-4xxxxxx Series Motors: ELAU’s matched servo motors (e.g., MC-4Hxx series) are optimized for use with the MC-41110400 drive, featuring high-resolution feedback and optimal torque characteristics for dynamic motion.

ELAU EPX-0xxxx Power Supply Module: Provides the regulated DC bus power for a cabinet of MC-41110400 drives, enabling efficient regenerative energy sharing between axes.

ELAU C400 I/O Modules: A range of digital and analog I/O modules (e.g., MC-4DI16) that connect directly to the EtherCAT network managed by the MC-41110400. for sensor and actuator interfacing.

ELAU Safe Logic Module (SLM): Expands the safety capabilities beyond STO, providing safe motion functions like Safe Limited Speed (SLS) or Safe Direction, working in conjunction with the MC-41110400.

Schneider Electric Magelis HMIs: Graphic terminals that provide the operator interface, communicating directly with the MC-41110400 controller via Ethernet for visualization and data exchange.

PacDrive 3 Engineering Software: The integrated development environment (IDE) used to program the logic, motion, and HMI for the entire system centered on the MC-41110400.

Single Cable Technology (SCT) Motor Feedback Cables: Specialized cables that combine power and high-resolution feedback in a single connection from the MC-41110400 drive to the motor, simplifying wiring.

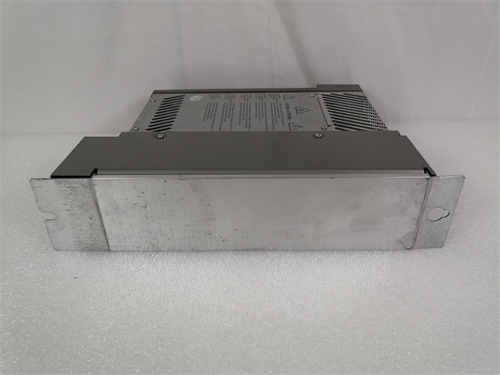

Installation, Maintenance, and Full-Cycle Support

Installation of the ELAU MC-41110400 is designed for modular machine building. The drive mounts on a standard DIN rail within a control cabinet. Connections include three-phase power input, DC bus links (for multi-drive systems), motor power and feedback, EtherCAT In/Out, and safety (STO). Initial setup and configuration are performed entirely through the intuitive PacDrive software, which auto-detects hardware and provides wizards for motor tuning. The compact design saves panel space, and its wide operating temperature range ensures reliability.

Routine maintenance primarily involves ensuring adequate cooling airflow and checking electrical connections. The drive provides comprehensive diagnostic information through its status LEDs and the engineering software, allowing for proactive health monitoring. Firmware updates can be applied online. Should a hardware fault occur, the modular design allows for quick replacement; the drive configuration is stored in the project file and can be downloaded to a new unit rapidly. We provide complete lifecycle support for the ELAU MC-41110400. from initial system architecture design and software training to technical troubleshooting and guaranteed access to genuine spare parts. Our experts can help you leverage the full potential of this integrated control platform to optimize your machine performance.

Unify your machine’s logic and motion control for peak performance. Contact us for a tailored solution featuring the ELAU MC-41110400.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: