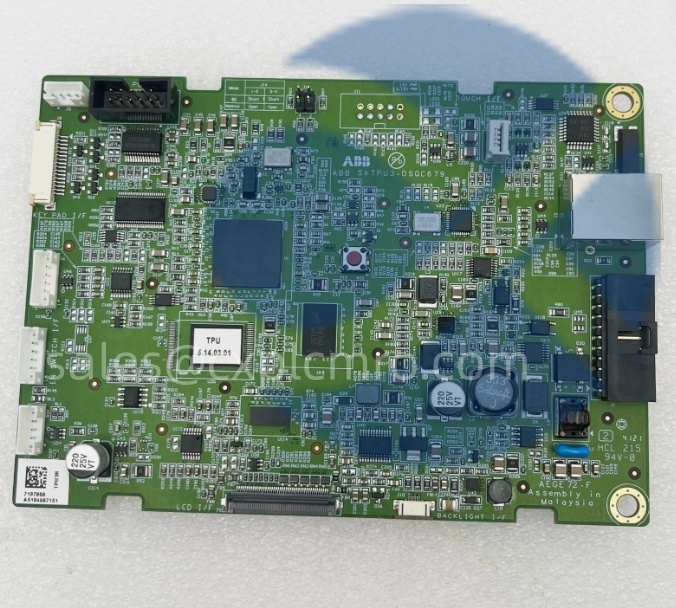

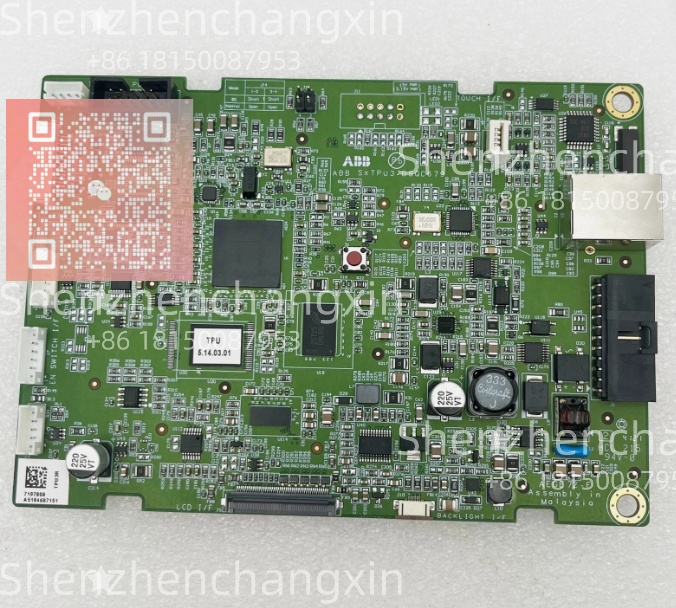

Description

Application Scenarios

In a Tier-1 automotive body shop, an ABB IRB 6700 robotic welding cell relied on discrete I/O for gun triggering and part presence signals, resulting in unreliable sequencing and frequent line stoppages due to signal noise. Engineers installed the ABB DSQC679 (3HAC028357-001) module into the IRC5 controller and migrated all peripheral devices—including weld timers, clamp sensors, and vision systems—onto a single DeviceNet trunk. The result: cycle time reduced by 12%, wiring harnesses cut by 60%, and communication errors eliminated. During a critical production ramp-up, the DSQC679’s built-in diagnostics quickly identified a faulty end-of-arm tooling node, minimizing downtime. The module’s seamless integration with RobotStudio also allowed offline simulation of the entire DeviceNet network—accelerating commissioning by three days.

Technical Principles and Innovative Values

Innovation Point 1: Dual-Mode Operation (Master/Slave)

The DSQC679 can act as a DeviceNet master to orchestrate an entire cell (e.g., polling sensors and actuators) or as a slave to respond to commands from a higher-level PLC—offering unmatched flexibility in system architecture.

Innovation Point 2: Tight Integration with RAPID & RobotStudio

I/O mapping is configured directly in RobotStudio using symbolic names. In RAPID code, signals appear as standard DI/DO or GI/GO, enabling seamless logic without low-level protocol handling.

Innovation Point 3: Real-Time Determinism with Low Jitter

DeviceNet’s CAN-based protocol ensures cycle times as low as 2 ms, critical for synchronized motion (e.g., tracking on conveyors) and safety interlocks.

Innovation Point 4: Simplified Troubleshooting

Onboard LEDs indicate network status, while the Event Log in the FlexPendant displays detailed DeviceNet errors (e.g., “Node 12 offline” or “Baud rate mismatch”), accelerating diagnostics.

Application Cases and Industry Value

At an electronics assembly facility in Southeast Asia, six ABB IRB 1200 robots performed precision pick-and-place operations. Each robot required coordination with vision systems, part feeders, and reject gates. By installing a DSQC679 (3HAC028357-001) in every controller, the integrator created independent DeviceNet networks per cell. This eliminated cross-talk, reduced cabinet space, and allowed standardized I/O templates across all stations. Over one year, the plant achieved 99.8% uptime and cut spare parts inventory by consolidating to a single fieldbus standard. Maintenance staff reported that replacing a failed sensor now took under 10 minutes—thanks to plug-and-play DeviceNet nodes and clear diagnostics from the DSQC679.

Related Product Combination Solutions

ABB DSQC652: Digital I/O module (often used alongside DSQC679 for local signals)

ABB DSQC653: Analog I/O module for pressure, temperature, or position feedback

ABB IRC5 Controller: Main robot controller chassis (e.g., 3HAC026253-001)

ABB OmniCore C90XT: Next-gen controller compatible with DSQC679

Allen-Bradley 1791DS: Compact DeviceNet I/O block commonly used with ABB robots

ABB RobotStudio: Offline programming and network configuration software

ABB 3HAC028358-001: DSQC679 mounting bracket or spare kit (if applicable)

ODVA Certified DeviceNet Cables: Shielded trunk/drop cables for noise immunity

Installation, Maintenance, and Full-Cycle Support

Installation of the ABB DSQC679 (3HAC028357-001) requires powering down the IRC5/OmniCore controller, inserting the module into an available slot (typically in the I/O section), and connecting a shielded DeviceNet cable via the M12 port. Configuration is done in RobotStudio: define the network topology, assign node addresses, and map I/O to RAPID signals.

For maintenance, always check the three status LEDs:

Green (RUN): Module operational

Yellow (NET): DeviceNet active

Red (ERR): Fault (e.g., short circuit, missing node)

We supply only genuine, new-in-box ABB DSQC679 (3HAC028357-001) modules, each tested for electrical integrity, boot sequence, and DeviceNet handshake functionality. Every unit includes a 12-month warranty and full traceability (manufacture date, batch code). Our ABB-certified robotics engineers provide remote support for network commissioning, including baud rate optimization, EDS file integration, and troubleshooting communication timeouts.

Contact us to streamline your robotic cell integration—because when milliseconds matter and reliability is non-negotiable, the ABB DSQC679 delivers robust, real-time connectivity you can trust.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: