Description

Application Scenarios

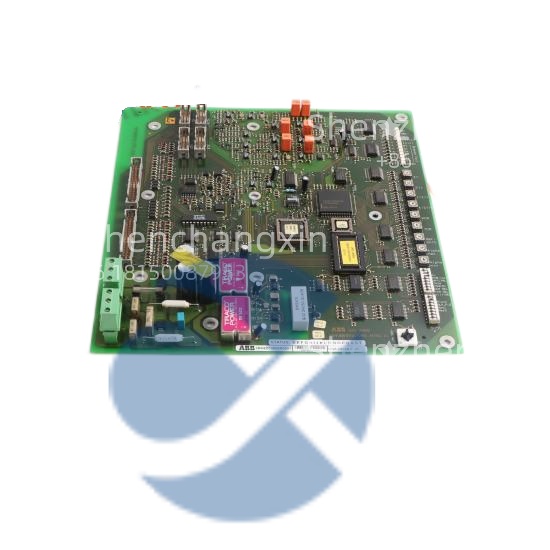

At a North American natural gas compressor station, an ACS1000 drive began failing to start after routine maintenance. Diagnostics revealed corrupted firmware and intermittent CAN bus errors traced to a degraded XVC767AE102 (3BHB007209R0102) board—its EEPROM had failed due to voltage spikes from a nearby VFD. Replacing the board and reloading the application-specific configuration restored full functionality within 4 hours, avoiding a $ 250.000/day throughput penalty. In an Australian mining operation, proactive stocking of XVC767AE102 units allowed rapid recovery after a lightning-induced surge damaged multiple drive control boards—demonstrating its strategic value in remote sites with limited logistics.

Technical Principles and Innovative Values

Innovation Point 1: Real-Time Synchronization Across Power Stacks

The XVC767AE102 uses high-speed optical links to synchronize gate pulses across all three phases with nanosecond-level precision, ensuring balanced inverter operation and minimizing harmonic distortion.

Innovation Point 2: Multi-Layer Fault Containment Architecture

It implements hierarchical protection: local faults (e.g., desaturation) are handled by gate drivers, while system-level faults (e.g., DC bus overvoltage) are managed centrally—with automatic logging and safe shutdown sequencing.

Innovation Point 3: Modular Firmware for Application Flexibility

The same hardware supports pump, fan, compressor, or conveyor profiles via downloadable firmware packages, reducing inventory complexity for end users.

Innovation Point 4: Built-In Diagnostics & Predictive Health Monitoring

Monitors its own supply voltages, temperature, and communication integrity—reporting early warnings via the HMI or remote SCADA system before catastrophic failure occurs.

Application Cases and Industry Value

In a European district heating plant, XVC767AE102 boards enabled seamless integration of ACS1000 drives into a Modbus TCP network—allowing remote speed control based on outdoor temperature. During a winter peak, this flexibility saved over 8% in energy costs. In Chile, a copper concentrator uses these boards in 12 MW mill drives; their robust design has withstood years of dust, vibration, and humidity—proving reliability in extreme mining conditions. Maintenance teams consistently rate the XVC767AE102 as “the most critical single point of failure” in the ACS1000 architecture—hence the need for spares.

Related Product Combination Solutions

ABB XVC767AE102 (3BHB007209R0102) + VCU736AE101 – Full ACS1000 control hierarchy (if applicable)

ABB XVC767AE102 + GVC736BE101 / DATX130 – Complete drive control-to-power chain

ABB CDP312R Operator Panel – Local HMI interface for parameter access

ABB LWN2660-6EG (3BHL000986P7002) – Current sensor providing feedback to XVC767AE102

ABB Fiber Optic Cables (e.g., 3BSE00383R1) – For noise-immune communication to power stacks

ABB PCM600 / DriveComposer Pro – Engineering software for configuration, backup, and firmware upload

ABB 3BHB007209R0103 – Potential revision or region-specific variant (verify compatibility)

ABB ACS1000 Spare Parts Kit – Includes control boards, sensors, fans, and fuses

Installation, Maintenance, and Full-Cycle Support

Installation of the XVC767AE102 requires:

ESD-safe handling (wrist strap, grounded workstation)

Verification of all ribbon cables, fiber connectors, and backplane seating

Firmware reload using ABB’s official tools and site-specific backup files

Maintenance best practices:

Annual inspection for capacitor bulging, connector corrosion, or dust buildup

Backup of drive parameters and application code before any intervention

Thermal imaging during operation to detect abnormal hot spots

We test every 3BHB007209R0102 for basic functionality, memory integrity, and communication ports. Units are stored in climate-controlled, anti-static environments and shipped in foam-lined, shielded packaging. All sales include a 12-month warranty and access to technical support for cross-referencing and compatibility checks.

Note: As part of Hitachi Energy, ABB continues to support legacy ACS1000 components like the XVC767AE102 through global service networks, long-term component programs, and firmware archives.

Contact us for genuine XVC767AE102 / 3BHB007209R0102 control boards, firmware assistance, configuration backups, or engineering consultation—because when your multi-megawatt drive depends on one intelligent board, uptime starts with the right spare.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email:

.jpg)