Description

Product Description:

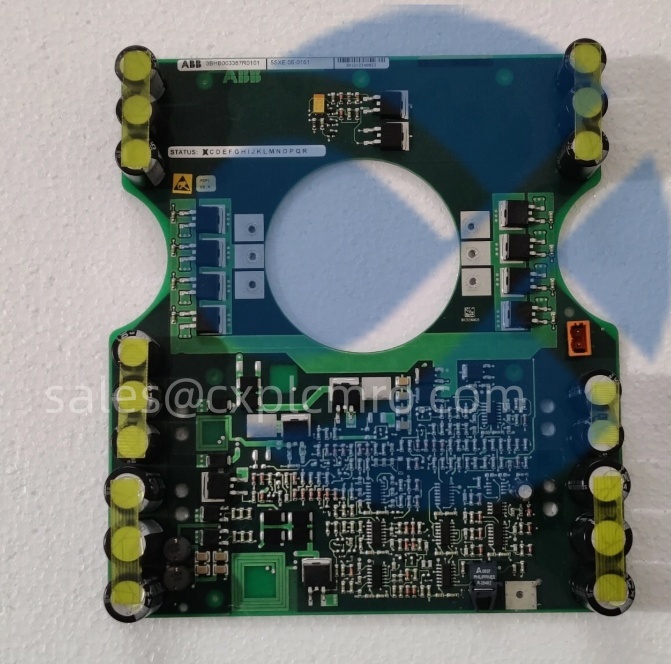

The ABB 3BHB021400R0101 is a key module in ABB’s industrial automation series, typically used as an interface, control, or signal processing unit in control systems, drive systems, or large-scale automation solutions. Designed to provide high reliability and precise performance in demanding industrial environments, this module is a core component for implementing complex control logic, data exchange, or system function expansion. It reflects ABB’s deep technical expertise in industrial automation and its high standards for system stability and reliability.

Application Scenario:

In a large chemical plant’s compressor control system, multiple large units need to operate collaboratively, with extremely complex start-up sequences, load distribution, and anti-surge control logic. This system is built on ABB’s AC 800M or similar advanced controller platform. The ABB 3BHB021400R0101 module might serve as a dedicated control interface or auxiliary processing unit in this scenario. It is responsible for acquiring and pre-processing high-speed signals from multiple vibration sensors, temperature transmitters, and pressure switches. Subsequently, it transmits the processed data and status information in real-time to the main controller via a high-speed bus (such as Profibus DP or the manufacturer’s internal bus). The main controller then executes complex control algorithms based on this information, precisely adjusting the inlet guide vanes and anti-surge valves. The stable operation of this module ensures the integrity of the signal chain, allowing the compressor to operate smoothly in the efficient zone, preventing unit trips due to signal loss or delay, and guaranteeing the safety and stability of continuous production. Its value is directly reflected in the availability and safety of the production line.

Core Parameters:

Parameter Category

Details

Manufacturer Model

3BHB021400R0101

Manufacturer

ABB

Product Type

Industrial Control/Interface/Function Module

Typical Series Affiliation

May belong to the ABB AC 800M controller series, S800 I/O series, or be an auxiliary control unit for drive systems (such as ACS 800/ACS 880).

Main Functions

Signal processing, protocol conversion, dedicated control logic execution, I/O expansion, or system communication interface. Communication Interface

May support one or more industrial bus protocols, such as Profibus DP, Profibus PA, Modbus, or ABB proprietary bus.

Electrical Interface

Typically includes removable terminal blocks or connectors for connecting field signals (digital/analog) and system power.

Operating Voltage

Commonly 24V DC or powered via the backplane.

Operating Environment

Designed for standard industrial control cabinet environments, with a wide operating temperature range and good electromagnetic interference immunity.

Key Features

High reliability, modular design, easy integration into existing ABB system architecture.

Technical Principles and Core Values:

Core Value One: Achieving deterministic high-speed signal processing and system integration. This module is not simply a signal relay station. It typically integrates a dedicated microprocessor and signal conditioning circuits, capable of high-precision digitization, filtering, and linearization of raw industrial signals (such as 4-20mA, thermocouple millivolt signals, and discrete signals). The processed standard data is exchanged periodically and deterministically with the main controller through its internal high-speed bus interface. This “pre-processing-then-transmission” mode greatly reduces the computational load on the main controller, improving the response speed and data processing capabilities of the entire control system, especially suitable for complex processes requiring fast closed-loop control.

Core Value Two: Providing high-reliability electrical isolation and system protection. The module places great emphasis on system safety and stability in its design. Its input/output channels typically use opto-isolation or transformer isolation technology, effectively blocking common-mode voltage, surges, and ground loop interference that may exist on the field side, preventing faults from spreading from the field side to the expensive control system core. At the same time, the module has comprehensive power monitoring and watchdog functions, and can automatically enter a preset safe state (such as output hold, zeroing, or entering a predefined value) when it detects its own abnormality or communication interruption, minimizing the risk of equipment malfunction and ensuring the safety of the process and personnel.

Core Value Three: Modular design provides the system with high flexibility and scalability. As part of the ABB automation ecosystem, this module adheres to strict modular design standards. Users can flexibly configure and combine different functional modules on racks or rails, much like building with blocks, according to specific control requirements (such as needing more AI points, specific communication protocols, etc.). This design makes the system highly customizable in the initial stages of a project and extremely convenient for later modifications or expansions. Simply adding or replacing the corresponding modules is sufficient, without needing to change the entire control system architecture, effectively protecting the user’s initial investment and reducing maintenance costs throughout the system’s lifecycle.

Application Cases and Industry Value:

Case Study: Paper Mill Rewinder Tension Control System Upgrade. A paper mill’s rewinder control system was aging, and unstable tension control led to wrinkles and paper breaks, severely impacting yield and production efficiency. The upgrade solution adopted a new system centered around the ABB AC 800M. In this system, the ABB 3BHB021400R0101 module was used as a high-speed analog input and dedicated tension control interface module. It directly connects to the tension sensor and encoder, reading tension values and line speed at a very high sampling rate. The dedicated algorithm embedded in the module performs real-time filtering and calculations on the signals, and sends precise tension feedback and speed signals to the main controller via a high-speed fieldbus. The main controller achieves ultra-precise constant tension control by accurately adjusting the torque of the front and rear roller motors. After the upgrade, the paper break rate decreased by 85%, product quality improved significantly, and the tightness and flatness of the paper rolls reached high standards. The project manager summarized that the high-precision, high-speed signal processing capabilities provided by the 3BHB021400R0101 module were the key technological foundation for this successful upgrade, and the investment was recouped in just a few months through reduced waste and increased production.

Related Product Combination Solutions:

This module is a node in ABB’s vast family of automation products. Common components that work in conjunction with it in a typical control station or drive cabinet include:

Main Controller: Such as the ABB PM803F or AC 800M series CPU, which is the brain of the entire system, with this module acting as an extension of its “senses” or “limbs”. Power Supply Module: Such as the ABB SD822 or TU833 power supply unit, providing stable and reliable operating power for all modules, including the 3BHB021400R0101.

Communication Module: Such as the ABB CI857K01 (Profibus DP master module), used to connect this module or other slave devices, or to achieve data exchange with the upper-level network.

Other I/O Modules: Such as ABB AI810 (analog input), DI810 (digital input), DO810 (digital output), etc., together forming a complete signal acquisition and execution system.

Backplane/Base Unit: Such as the ABB TU832 or S800 backplane, providing mechanical mounting, electrical connection, and data communication for all modules.

Engineering Software: ABB Control Builder Plus/Professional, used for configuration, parameter setting, and programming of the entire hardware system (including this module).

Installation, Maintenance, and Full Lifecycle Support:

Installation and Commissioning: Installing the ABB 3BHB021400R0101 module requires following standard procedures. First, ensure the system is powered off. Securely insert it into the designated backplane or rack slot and tighten the fixing device. Then, correctly connect the field signal lines and power lines according to the drawings. After powering on, configure the hardware using ABB’s engineering software (such as Control Builder), including setting the module type, address, and the signal type, range, and filtering parameters of each channel. Finally, perform signal loop testing to ensure that field signals can be correctly read and processed.

Maintenance and Troubleshooting: This module is designed to be maintenance-free. Routine maintenance mainly involves keeping the control cabinet clean and ensuring good heat dissipation. The module itself usually has status indicator lights (such as PWR, RUN, ERR, etc.), which are the first source of information for quick diagnosis. When a fault occurs, first check the specific error code using the software diagnostic tool, and then check whether the power supply and communication cable connections are reliable. If a module hardware fault is confirmed, the standard procedure is to replace the entire module. In systems that support hot-swapping, replacement can be performed without powering off (ensure the system supports this and follow safety procedures); otherwise, the system must be shut down for replacement. Full Lifecycle Support: We provide full lifecycle support services for the ABB 3BHB021400R0101 module. From initial product selection and spare parts inquiry to providing brand-new original or rigorously tested and qualified refurbished parts, we ensure that their performance and reliability meet original factory standards. We can also provide relevant technical documentation support. After you replace the module, we recommend performing complete circuit testing and system function testing to ensure seamless integration. Our goal is to be your reliable automation spare parts partner, ensuring the continuous and stable operation of your critical control systems.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: