Description

The EMERSON KJ2201X1-HA1is a high-performance,redundant controller module central to the Emerson Ovation distributed control system(DCS).Designed for mission-critical applications,it provides the powerful and reliable computing engine needed to execute complex control strategies,data acquisition,and network communication for large-scale industrial processes.

Application Scenarios

In a combined-cycle power plant,the seamless coordination between gas turbines,steam turbines,and balance-of-plant systems is crucial for efficiency and grid stability.A controller failure could lead to a unit trip,causing massive financial loss and grid instability.Here,the EMERSON KJ2201X1-HA1controller is deployed in a redundant pair.The primary controller executes advanced regulatory and sequencing logic for the entire turbine island,while the standby KJ2201X1-HA1maintains a mirrored state in real-time.During a scheduled software update or an unexpected hardware fault,control automatically and bumplessly transfers to the backup unit with zero interruption to plant operation.Its value lies in delivering mainframe-level reliability and deterministic control performance,ensuring 24/7 availability for processes where downtime is not an option.

Parameter

Main Parameters

Value/Description

Product Model

KJ2201X1-HA1

Manufacturer

EMERSON(Emerson Process Management)

Product Category

DCS Controller/Processor Module

System Platform

Ovation Distributed Control System(DCS)

Architecture

High-availability,redundant configuration capable.

Processing Core

High-performance processor for fast,deterministic scan cycles.

Memory

Substantial integrated memory for application logic,point database,and history.

Controller Redundancy

Supports 1:1 hot-standby redundancy with automatic bumpless switchover.

I/O Capacity

Manages a large number of I/O points across multiple Ovation I/O branches.

Network Interfaces

Integrates with Ovation’s high-speed,fault-tolerant networks(e.g.,Ovation Ethernet,Fault Tolerant Ethernet).

Typical Applications

Boiler/Turbine control(BOP),high-speed regulatory control,complex sequencing.

Key Feature

Designed for the most demanding,high-availability process control applications.

Technical Principles and Innovative Values

Innovation Point 1:True Fault-Tolerant Architecture for Continuous Operation:The KJ2201X1-HA1is engineered from the chip level up for high availability.In a redundant pair,the primary and standby controllers are synchronized over a dedicated,high-speed link.The standby unit continuously updates its entire memory image,including process data and control logic state.This enables a switchover in the event of any single fault—power,hardware,or network—with no loss of control,no”bump”to the process,and no need for re-initialization,a critical feature for turbine and boiler control.

Innovation Point 2:Deterministic Performance for Mixed Control Types:Unlike generic controllers,the KJ2201X1-HA1provides a predictable,deterministic execution environment.It can seamlessly blend high-speed regulatory control loops(like burner management or turbine valve control)with complex sequential logic and data handling within a single,unified platform.This eliminates the latency and integration challenges of using separate systems,providing a cohesive and reliable control strategy for an entire plant unit.

Innovation Point 3:Deep Integration with Ovation’s Optimized Ecosystem:The controller’s performance is amplified by its native integration with the Ovation system.It communicates with I/O modules via a high-speed,deterministic backplane,ensuring data freshness.Its embedded networking provides seamless connectivity to operator interfaces,historians,and other controllers.This deep integration simplifies engineering,enhances diagnostics,and optimizes data flow from field device to the enterprise.

Application Cases and Industry Value

Case Study:Supercritical Coal-Fired Power Plant Modernization

A utility company needed to modernize the aging control system of a 600 MW supercritical unit to improve efficiency,reliability,and emissions compliance.The existing system suffered from slow response times,limited redundancy,and high maintenance costs.

Solution&Implementation:

The core of the new DCS was the Emerson Ovation system,with triple-redundant EMERSON KJ2201X1-HA1controllers managing the critical boiler and turbine control loops.These controllers executed advanced coordinated control systems(CCS),burner management,and sootblower sequencing.Their high-speed processing and deterministic scan rates were crucial for tight combustion control.

Results and Value Delivered:

Enhanced Reliability and Availability:The redundant KJ2201X1-HA1controllers eliminated unplanned unit trips caused by control system failures.The plant reported a significant increase in availability,directly boosting revenue.Scheduled maintenance on controllers could be performed online without process impact.

Improved Efficiency and Emissions:The precise,advanced control enabled by the powerful KJ2201X1-HA1processors allowed operators to run the unit closer to its optimal setpoints.This resulted in a measurable reduction in heat rate(improved efficiency)and tighter control of NOx emissions,helping meet environmental regulations.

Reduced Lifecycle Costs:The modern,supported platform reduced spare parts costs and obsolescence issues.The powerful diagnostics and standard engineering tools simplified troubleshooting and reduced maintenance labor hours.

Related Product Combination Solutions

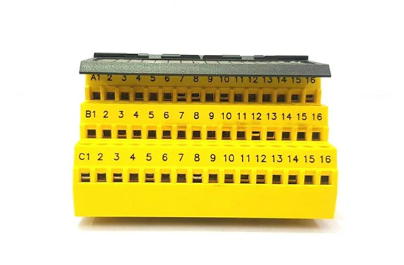

Ovation I/O Modules(e.g.,Analog Input KJ3221,Digital Output KJ3202):These are the field interface modules that connect sensors and actuators to the KJ2201X1-HA1controller via high-speed I/O networks,forming the complete control loop.

Ovation Power Supplies(e.g.,for controller chassis):Dedicated,often redundant,power supplies are required to provide clean,reliable power to the chassis housing the KJ2201X1-HA1controller.

Ovation Workstations&Servers:Operator stations(HMI)and historian servers that connect to the KJ2201X1-HA1over the plant network,providing the human interface and data logging for the processes it controls.

Ovation Network Switches(e.g.,Fault Tolerant Ethernet Switches):The network infrastructure that provides the high-speed,redundant communication backbone linking multiple KJ2201X1-HA1controllers and other system nodes.

Emerson AMS Device Manager:While not a physical module,this software integrates with the Ovation system,allowing for advanced configuration and predictive diagnostics of field devices connected to the KJ2201X1-HA1,extending intelligence to the field.

Controller Synchronization Hardware:Specific cables and termination modules required to establish the high-speed synchronization link between a primary and standby KJ2201X1-HA1controller pair.

Installation,Maintenance,and Full-Cycle Support

Installation of the EMERSON KJ2201X1-HA1is performed within a system chassis,requiring careful handling and proper ESD precautions.The module is keyed and slides into its dedicated slot.Critical to the installation is the proper connection of redundant power feeds,network cables,and synchronization cables to its partner in a redundant configuration.Commissioning is performed using the Ovation Developer Studio software,where the controller is configured,its control logic is downloaded,and redundancy parameters are established.

Routine maintenance is largely predictive and software-based.The controller’s health,temperature,and status are continuously monitored through the Ovation operator station.The hot-swap capability in a redundant system allows for the proactive replacement of a controller showing warning diagnostics without a plant shutdown.For a failed controller,replacement involves powering down the chassis(or relying on the redundant partner),swapping the module,and allowing the new unit to automatically synchronize from its peer or download its configuration from the network.

We provide comprehensive lifecycle support for the EMERSON KJ2201X1-HA1controller.Our services include compatibility verification for your specific Ovation system version,supply of genuine and tested modules,and expert technical assistance.We understand the critical nature of this component and can facilitate rapid delivery to minimize system downtime.Our support extends to helping with configuration management and best practices for maintaining your high-availability control system.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: