Description:

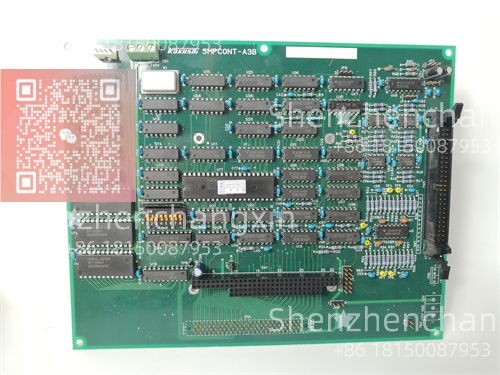

The KOKUSAI CXP-544A KOMS-A2is a critical system communication or control processor module designed for KOKUSAI semiconductor fabrication equipment,such as Chemical Vapor Deposition(CVD)or diffusion furnaces.This module acts as a core component within the tool’s machine control system,managing data exchange,I/O processing,and execution of equipment control sequences to ensure precise and reliable wafer processing.

Application Scenarios:

Within a KOKUSAI vertical diffusion furnace,the precise ramp-up,stabilization,and cool-down of wafer temperatures over several hours is governed by a complex recipe.This recipe,along with commands for gas valve sequencing and pressure control,is managed by the tool’s central controller.The KOKUSAI CXP-544A KOMS-A2module serves as a vital communication node or dedicated process controller in this hierarchy.It may interface directly with temperature controllers,MFCs(Mass Flow Controllers),and pressure gauges,executing low-level control loops and reporting real-time sensor data back to the host.In this application,the reliability and deterministic performance of the CXP-544A KOMS-A2are paramount;any communication lag or processing fault could lead to a non-conforming temperature profile,resulting in a batch of scrapped wafers worth hundreds of thousands of dollars.Its role is to be the silent,reliable executor of the critical commands that define the semiconductor manufacturing process.

Parameter:

Main Parameters

Value/Description

Product Model

CXP-544A KOMS-A2

Manufacturer

KOKUSAI(Kokusai Electric Corporation)

Product Category

Equipment Control/Communication Processor Module

Compatible Tool

KOKUSAI Semiconductor Manufacturing Equipment(e.g.,CVD,Diffusion Furnaces)

Primary Function

Machine Control,I/O Handling,Inter-module Communication

Processor

Dedicated microprocessor or industrial-grade CPU

Memory

RAM for program execution,non-volatile memory for firmware/parameters

Communication Interfaces

Likely includes proprietary KOKUSAI backplane bus,serial(RS-232/422/485),and possibly Ethernet for host communication

I/O Handling

Manages digital and analog signal interfaces for sensors and actuators

Operating Temperature

Designed for controlled industrial environments(e.g.,0°C to 60°C)

Power Requirement

Powered from the equipment’s internal power supply via backplane

Mounting

Installs into a dedicated slot on the tool’s control unit rack or backplane

Technical Principles and Innovative Values:

Innovation Point 1:Deterministic Real-Time Control for Process Integrity.The core value of the CXP-544A KOMS-A2lies in its ability to provide deterministic,real-time control within the stringent environment of a semiconductor tool.It is engineered to execute control loops and sequence steps with guaranteed timing,independent of higher-level system load.This is non-negotiable for processes like thermal budgeting in a furnace,where a millisecond delay in closing a valve or adjusting a heater can affect film properties.The module’s hardware and firmware are optimized for this predictable,low-latency response,forming the bedrock of process repeatability.

Innovation Point 2:Deep Integration with the KOKUSAI Equipment Ecosystem.The module is not a generic PLC card;it is specifically architected for KOKUSAI’s machine control architecture(often referenced as the KOMS system).It communicates seamlessly over proprietary high-speed data highways with other dedicated controllers(for temperature,pressure,gas)and the main equipment controller.This native integration ensures optimal data throughput,synchronized operation,and access to comprehensive,tool-specific diagnostic messages that are essential for rapid maintenance and troubleshooting,reducing machine downtime.

Innovation Point 3:Robust Design for 24/7 Semiconductor Fab Operation.Semiconductor tools operate continuously.The CXP-544A KOMS-A2is built for this demanding duty cycle with high-grade components and conservative thermal design.It incorporates robust error-checking and fault-reporting mechanisms.In many configurations,critical functions may be supported by redundant modules or paths.This design philosophy minimizes the risk of an unscheduled tool down(UTD)event caused by the control electronics,directly contributing to maximizing tool availability and overall factory throughput.

Application Cases and Industry Value:

Case Study:Poly-Si Deposition Process Stability in a Memory Fab.A major memory chip manufacturer was experiencing subtle,intermittent thickness variations in polysilicon layers deposited in their KOKUSAI batch CVD furnaces,impacting device yields.Diagnostics pointed to occasional timing jitter in the gas injection sequence during the critical nucleation phase.

Engineering analysis suspected a marginal communication module in the gas control subsystem.The specific KOKUSAI CXP-544A KOMS-A2module responsible for coordinating the MFCs and valve manifolds was identified.It was replaced with a new,certified unit.Post-replacement,data logging showed the gas step transitions became perfectly sharp and repeatable.Subsequent wafer runs showed a 15%reduction in within-wafer thickness non-uniformity and the elimination of the intermittent yield detractor.The fab engineering team concluded that the renewed CXP-544A KOMS-A2module restored the deterministic performance of the gas delivery sequence,showcasing how a single,highly specialized control component can have a direct,measurable impact on multi-million dollar production yields.

Related Product Combination Solutions:

The CXP-544A KOMS-A2operates within a hierarchy of controllers.Key related KOKUSAI OEM parts include:

Main Equipment Controller(e.g.,KOMS-CPU-xxxx):The primary system computer that runs the user interface and overall recipe,which coordinates with the CXP-544A KOMS-A2.

Temperature Controller Modules:Dedated PID controller cards(e.g.,KOMS-TC-xxxseries)that the CXP-544Amay supervise or exchange setpoints with.

I/O Expansion Modules:Additional digital and analog I/O cards that extend the system’s field interface capability.

Power Supply Units(PSUs):The specific,regulated power supplies for the control rack that provide clean power to the CXP-544A KOMS-A2and other cards.

Communication Gateway Modules:Cards that facilitate communication between the proprietary KOKUSAI control network and external fab hosts(e.g.,via SECS/GEM).

Operator Interface Panel/HMI:The touchscreen or display unit that allows technicians to interact with the system,displaying status information managed by controllers like the CXP-544A.

Installation,Maintenance,and Full-Cycle Support:

Installation of this module is a precise operation performed by qualified technicians.It involves powering down the relevant section of the tool,carefully inserting the card into its designated slot on the control rack backplane,and securing it.Re-assembly and power-up are followed by a system initialization and self-test sequence.Configuration is typically done through the tool’s proprietary service software,where the module is recognized,and its firmware/parameters are verified or downloaded.

Preventive maintenance involves monitoring the module’s status through the equipment’s diagnostic screens,checking for error logs,and ensuring the control rack’s cooling is functional.The module itself has no user-serviceable parts.If diagnostics indicate a hardware failure,the standard procedure is a board-level swap.We provide critical support for this lifecycle.Our CXP-544A KOMS-A2modules are sourced from specialized channels catering to the semiconductor OEM aftermarket.Prior to dispatch,each unit undergoes a rigorous validation process,including electrical testing,firmware verification,and basic functional checks where possible.We offer traceability and technical guidance for integration,helping to minimize the downtime of your capital-intensive production equipment.

UFC921A101 3BHB024855R0101 UFC911B106 3BHE037864R0106 UDC920BE01 3BHE034863R0001 XVC770BE101 3BHE021083R0101 KUC755AE105 3BHB005243R0105 LXN1604-6 3BHL000986P7000 LWN2660-6E 3BHL000986P7002 UFC789AE 38HE014022P102 3BHL000734P0003 SLOV4.6/5.3 HIES308461R0012 HIES208441R.. ID8A92485001/022 3BHB009410R000 SG000247 3BHL000986P1006 XVC724BE101 3BHE009017R0102 DKTFM418B 3BHB015651P0001 PU180/63E 3BHB00916230001 HIES308461R0012 FPX86-9345–B 3BHL000986P0006 3BHL000734P0003 SLOV4.6/5.3 UFC921A101 3BHE024855R0101 PPC907BE101 3BHE024577R0101 XVC724BE101 3BHE009017R0102 IEC60129,62271-102 MI-CONP KUC755AE105 3BHB005243R0105 HIES308461R0012 MG160MD2-42FF300-F1 PTC 160℃ TP211 MG160MD2-42FF300-F1 ABB S-073N ALU 3BHB009884R5211 ABB S-093H 3BHB030478R0309 ABB S-123H 3BHB030479R0512 ABB UFC912A101 3BHE039426R0101 ABB 5SHY4045L0001 3BHB018162R0001 ABB S-113N 3BHB018008R0001 W4 KUC755AE105 3BHB005243R0105 HIEE401807R0001 3BHB046719R0008 STRAUB FLEX1L TB820V2 S-053M 3BHB012897R003 *12 3BHB014556R0001 3BHB010823R0002 CDP312R XVC768AE102 UFC789AE101 S-073N KU C755AE105 XVC770BE101 UFC760BE42 PPC907BE UFC760BE43 XVC769AE101 LDMTR-01 UAC389AE02 LTC391AE01 PPC905AE101 UAC383AE01 LDLPTR-01

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: