Description

The NI SCXI-1140 is an 8-channel,high-precision analog input module designed for accurate measurement of strain gauge,load cell,torque sensor,and other Wheatstone bridge-based transducers.Part of National Instruments’(now Emerson Test&Measurement)SCXI(Signal Conditioning eXtensions for Instrumentation)platform,it provides isolated,low-noise signal conditioning with programmable excitation voltage,remote sensing,and built-in shunt calibration—making it ideal for structural testing,materials research,and industrial force measurement applications.

Application Scenarios

At a leading aerospace R&D center,engineers were conducting full-scale fatigue tests on a new wing spar design.Traditional data acquisition systems suffered from thermal drift and crosstalk during long-duration cyclic loading,corrupting microstrain measurements.By deploying the NI SCXI-1140 in an SCXI-1000 chassis with a PXI controller running LabVIEW,the team achieved stable,24-bit resolution readings over 72-hour test cycles.The module’s remote sense feature compensated for lead-wire resistance changes due to temperature,while its onboard shunt calibration allowed daily verification without disconnecting sensors.The result:confidence in sub-5µε(microstrain)accuracy,enabling certification of the airframe ahead of schedule.

Parameter

Main Parameters Value/Description

Product Model SCXI-1140

Manufacturer National Instruments(NI),now part of Emerson Test&Measurement

Product Category Strain/Bridge Input Signal Conditioning Module

Number of Channels 8 independent differential inputs

Bridge Compatibility Supports quarter-,half-,and full-bridge configurations

ADC Resolution 24-bit sigma-delta

Excitation Voltage Programmable:2 V,5 V,or 10 V DC(±0.2%)

Excitation Current Up to 30 mA per channel

Remote Sense Yes—compensates for lead resistance

Shunt Calibration Built-in precision shunt resistor(typically 100 kΩ)per channel

Input Range±25 mV/V(e.g.,±250 mV at 10 V excitation)

Isolation Voltage 300 Vrms channel-to-channel and channel-to-chassis

Sampling Rate(per channel)Up to 2,400 samples/sec(aggregate up to 19.2 kS/s)

Compatibility SCXI chassis(e.g.,SCXI-1000,SCXI-1001);interfaces via DAQ devices(PCI/PXI/USB)

Software Support NI-DAQmx,LabVIEW,MATLAB,Python(via drivers)

Operating Temperature 0°C to+50°C

Technical Principles and Innovative Values

Innovation Point 1:True Remote Sense Architecture–Unlike basic bridge modules,the SCXI-1140 uses 6-wire connections(including sense+and sense–)to measure voltage directly at the bridge,eliminating errors from cable resistance changes due to temperature or length—critical for long cable runs in field testing.

Innovation Point 2:Per-Channel Shunt Calibration–Each channel includes a high-accuracy internal shunt resistor that simulates a known strain value,enabling automated system verification without physical access to sensors—ideal for embedded or inaccessible installations.

Innovation Point 3:High-Density Precision in Compact Form–Eight fully isolated,24-bit channels in a single SCXI slot reduce rack space and cost compared to discrete amplifiers,while maintaining laboratory-grade accuracy(<±0.05%gain error).

Innovation Point 4:Seamless LabVIEW Integration–Native support in NI-DAQmx and pre-built LabVIEW VIs accelerate application development for real-time strain visualization,FFT analysis,and automated pass/fail testing.

Application Cases and Industry Value

In an automotive crash test facility,the NI SCXI-1140 was used to monitor 64 strain gauges across a vehicle chassis during high-speed impacts.Eight SCXI-1140 modules(in two SCXI-1001 chassis)synchronized with a PXI-4472 dynamic signal analyzer captured transient loads at 10 kS/s aggregate rate.The system’s low noise floor(<1µV RMS)resolved subtle deformation modes that correlated with passenger injury metrics.Over three years,this setup contributed to five star safety ratings for three new models—demonstrating how the SCXI-1140 turns raw strain into life-saving engineering insight.

Related Product Combination Solutions

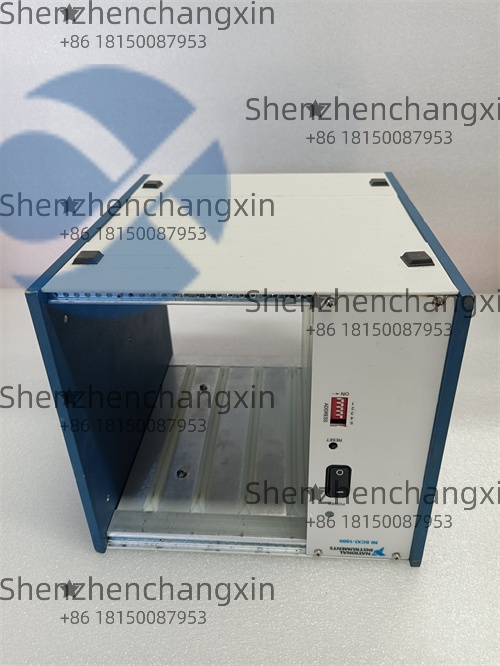

NI SCXI-1000/SCXI-1001:Modular chassis that houses the SCXI-1140 and connects to DAQ controllers.

NI PXIe-6368:High-performance X Series DAQ device that can control SCXI modules via an SCXI backplane.

NI TB-2708:Terminal block accessory for easy screw-terminal wiring of strain gauges to SCXI-1140.

NI SCC-SG24:Alternative single-channel strain module for SCC systems(lower density,higher bandwidth).

NI LabVIEW Full Development System:Software environment with built-in strain analysis toolkits(e.g.,Sound and Vibration,Control Design).

HBM QuantumX MX840A:Competitor solution—used when migrating from SCXI to modern Ethernet-based DAQ.

NI SCXI-1327:Shielded I/O connector kit for noise-sensitive environments.

NI Calibration Executive:Software for automating periodic calibration of SCXI-1140 using its shunt feature.

Installation,Maintenance,and Full-Cycle Support

Installing the NI SCXI-1140 involves mounting it in an SCXI chassis,connecting bridge sensors via the TB-2708 terminal block(or custom cabling),and linking the chassis to a host DAQ device(e.g.,PCI-6251).Wiring follows standard 6-wire(or 4-wire)strain gauge practices,with excitation+,excitation–,sense+,sense–,and signal±lines.Configuration is done in NI MAX or programmatically via DAQmx—where users set excitation level,bridge type,and units(e.g.,µε).

Maintenance includes periodic verification using the built-in shunt calibration and checking for loose terminals or damaged cables.The module is solid-state with no moving parts,offering>10-year service life under normal lab conditions.While NI has discontinued new SCXI production,we provide fully tested,refurbished SCXI-1140 units with recalibration certificates traceable to NIST standards.Our support includes legacy driver compatibility(Windows 10/11),LabVIEW migration assistance,and integration guidance for hybrid systems(e.g.,SCXI+CompactDAQ).

Note:The SCXI platform is considered legacy by NI/Emerson,but remains widely deployed in aerospace,civil engineering,and power testing labs due to its unmatched precision for static and quasi-static strain.We specialize in sustaining these systems with quality replacements and expert support.

UFC921A101 3BHB024855R0101 UFC911B106 3BHE037864R0106 UDC920BE01 3BHE034863R0001 XVC770BE101 3BHE021083R0101 KUC755AE105 3BHB005243R0105 LXN1604-6 3BHL000986P7000 LWN2660-6E 3BHL000986P7002 UFC789AE 38HE014022P102 3BHL000734P0003 SLOV4.6/5.3 HIES308461R0012 HIES208441R.. ID8A92485001/022 3BHB009410R000 SG000247 3BHL000986P1006 XVC724BE101 3BHE009017R0102 DKTFM418B 3BHB015651P0001 PU180/63E 3BHB00916230001 HIES308461R0012 FPX86-9345–B 3BHL000986P0006 3BHL000734P0003 SLOV4.6/5.3 UFC921A101 3BHE024855R0101 PPC907BE101 3BHE024577R0101 XVC724BE101 3BHE009017R0102 IEC60129,62271-102 MI-CONP KUC755AE105 3BHB005243R0105 HIES308461R0012 MG160MD2-42FF300-F1 PTC 160℃ TP211 MG160MD2-42FF300-F1 ABB S-073N ALU 3BHB009884R5211 ABB S-093H 3BHB030478R0309 ABB S-123H 3BHB030479R0512 ABB UFC912A101 3BHE039426R0101 ABB 5SHY4045L0001 3BHB018162R0001 ABB S-113N 3BHB018008R0001 W4 KUC755AE105 3BHB005243R0105 HIEE401807R0001 3BHB046719R0008 STRAUB FLEX1L TB820V2 S-053M 3BHB012897R003 *12 3BHB014556R0001 3BHB010823R0002 CDP312R XVC768AE102 UFC789AE101 S-073N KU C755AE105 XVC770BE101 UFC760BE42 PPC907BE UFC760BE43 XVC769AE101 LDMTR-01 UAC389AE02 LTC391AE01 PPC905AE101 UAC383AE01 LDLPTR-01

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: