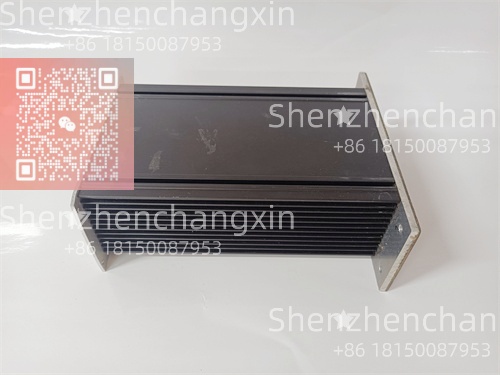

Description

The REXROTH VT-VSPA1-1-11 is a high-performance analog amplifier module developed by Bosch Rexroth for precise open-loop control of proportional directional valves in electro-hydraulic systems.Designed as a plug-in card for modular mounting systems(e.g.,VT-MSPA series carriers),it converts low-level analog command signals into high-current outputs that drive the solenoids of valves such as the 4WRPE or 4WRGE families.With built-in ramp generators,adjustable gain,dead-band compensation,and real-time diagnostics,the REXROTH VT-VSPA1-1-11 ensures smooth,repeatable motion control in industrial automation,test rigs,and mobile machinery.

Application Scenarios

In a steel mill’s continuous casting line,inconsistent slab thickness was traced to erratic hydraulic cylinder response caused by aging valve amplifiers with drifting gain settings.Engineers replaced legacy units with the REXROTH VT-VSPA1-1-11,leveraging its stable±10 V input interface and programmable ramp times to synchronize mold oscillation with strand speed.The result:thickness variation reduced from±3.2 mm to±0.8 mm,eliminating costly secondary grinding.Moreover,the module’s front-panel potentiometers allowed on-the-fly tuning during production—without PLC reprogramming—while its diagnostic LEDs instantly flagged a failing pressure sensor during a routine shift check,preventing a potential breakout incident.

Parameter

Main Parameters Value/Description

Product Model REXROTH VT-VSPA1-1-11

Manufacturer Bosch Rexroth AG

Product Category Analog Proportional Valve Amplifier(Open-Loop)

Input Signal±10 V DC(differential or single-ended)

Output Current Up to±1.5 A per channel(for 2-coil valves)

Valve Compatibility 4WRPE,4WRGE,4WRA,and other Bosch Rexroth proportional directional valves

Control Channels 1 valve(2 solenoids)–dual-output synchronized control

Ramp Time Adjustment Adjustable via onboard potentiometer(0.01–5 s)

Gain&Dead Band User-adjustable via precision trimmers for fine-tuning valve response

Diagnostics LED indicators for power,enable status,and fault(e.g.,coil short/open)

Mounting Plug-in module for VT-MSPA1 carrier(DIN rail compatible)

Supply Voltage 24 V DC(±10%)

Operating Temperature 0°C to+50°C

Certifications CE,UL 508,RoHS

Technical Principles and Innovative Values

Innovation Point 1:True Dual-Coil Synchronization–The REXROTH VT-VSPA1-1-11 independently controls both solenoids of a 4-way proportional valve but synchronizes their ramp profiles to prevent spool bias—critical for eliminating drift in position-critical applications like injection molding or fatigue testing machines.

Innovation Point 2:Field-Tunable Performance Without Software–Unlike digital amplifiers requiring laptops or software licenses,this analog module uses precision potentiometers for real-time adjustment of gain,dead zone,and ramp—ideal for commissioning teams in remote plants or harsh environments where electronics are restricted.

Innovation Point 3:Robust Fault Detection–Continuous monitoring of coil resistance detects opens,shorts,or ground faults,illuminating a red LED and disabling output to protect valves—reducing unplanned downtime in 24/7 operations like mining or marine winches.

Innovation Point 4:Modular Scalability–As part of the VT-MSPA ecosystem,multiple REXROTH VT-VSPA1-1-11 modules can be stacked on a single carrier,enabling multi-axis hydraulic control in compact panels—perfect for simulators or aerospace test stands.

Application Cases and Industry Value

At an automotive crash-test facility in Michigan,engineers needed millisecond-level repeatability in hydraulic actuator positioning to simulate consistent impact scenarios.Legacy amplifiers suffered from thermal drift during back-to-back tests,causing velocity deviations.After switching to the REXROTH VT-VSPA1-1-11,they achieved±0.5%repeatability across 50 consecutive runs,thanks to its temperature-stable analog circuitry and precise ramp control.The facility now certifies test data with higher confidence,accelerating vehicle safety approvals.

In another case,a wind turbine pitch system retrofit in Denmark used the REXROTH VT-VSPA1-1-11 to replace obsolete proprietary drivers.Its wide supply tolerance(21.6–26.4 VDC)handled voltage sags during grid disturbances,while the fast response(<20 ms)ensured reliable feathering during emergency stops.Maintenance crews appreciated the clear fault indication—reducing tower climbs by 60%.

Related Product Combination Solutions

REXROTH VT-MSPA1-1:Carrier module that houses up to 4 REXROTH VT-VSPA1-1-11 cards—ideal for multi-axis systems.

REXROTH 4WRPEH 10 C4 B/M-2X/G24K0/A1M:High-response proportional valve commonly driven by REXROTH VT-VSPA1-1-11 in dynamic applications.

REXROTH VT-VSPQA1-1-11:Digital upgrade path—same form factor but with CANopen interface and parameter storage.

REXROTH HMD01.1:Hydraulic motion controller that can send±10 V commands to REXROTH VT-VSPA1-1-11 for coordinated axis control.

REXROTH MS20:Pressure/flow sensor providing feedback for semi-closed-loop tuning when used with REXROTH VT-VSPA1-1-11.

REXROTH VT-VRPA1-52:Higher-current amplifier(±2.5 A)for larger valves—used when REXROTH VT-VSPA1-1-11 reaches power limits.

REXROTH IndraDrive Cs:Electric servo alternative—but in hybrid systems,REXROTH VT-VSPA1-1-11 handles auxiliary hydraulic axes.

REXROTH MTX Micro:Compact PLC that generates the±10 V setpoint signal for REXROTH VT-VSPA1-1-11 in standalone machines.

Installation,Maintenance,and Full-Cycle Support

Installing the REXROTH VT-VSPA1-1-11 requires mounting it onto a VT-MSPA1 carrier,connecting 24 VDC power,and wiring the±10 V command signal and valve coils.Shielded cables are recommended for noise immunity in VFD-rich environments.Initial setup involves adjusting gain to match valve flow characteristics and setting ramp times to avoid mechanical shock—tasks achievable in under 15 minutes using only a screwdriver.

Maintenance is minimal:periodic visual checks of LEDs and cleaning of ventilation slots suffice.In the event of a fault,the module’s clear diagnostics eliminate guesswork—no oscilloscope needed.Our service includes pre-calibrated units matched to common Rexroth valves,full functional test reports(including current waveform validation),and application-specific tuning guides.Every REXROTH VT-VSPA1-1-11 undergoes 48-hour burn-in and is backed by a 12-month warranty with technical support from certified Rexroth integration partners.

Contact us for a customized solution—whether you’re modernizing a hydraulic press,building a test bench,or ensuring reliability in mobile equipment,we deliver ready-to-install REXROTH VT-VSPA1-1-11 modules with expert application engineering support.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: