Description

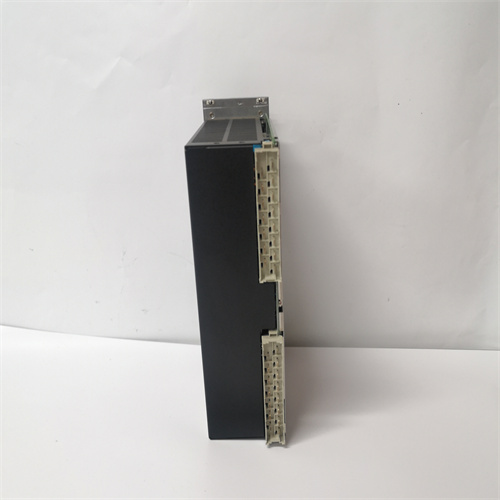

The VIBRO-METER VM600 MPC4 is a high-performance machinery protection card manufactured by Vibro-Meter (now Meggitt), a Swiss company, and designed specifically for the VM600 series machinery protection system (MPS). This card utilizes advanced digital signal processing (DSP) technology to simultaneously monitor four dynamic signal channels and two speed channels, providing continuous online vibration monitoring and protection for rotating machinery and critical equipment.

The VIBRO-METER VM600 MPC4 boasts high-precision measurement capabilities, accurately measuring vibration displacement, velocity, and acceleration with an accuracy of ±0.05% FS (full scale). The card supports various sensor types, including accelerometers, velocity sensors, and displacement sensors, and can monitor key parameters such as relative vibration, absolute vibration, Smax, eccentricity, and thrust position. Its highly configurable design and SIL2 safety certification make it widely used in rotating machinery protection systems in power generation, oil and gas, chemical, and steel industries.

Application Scenarios

In the Ninghai Power Plant Phase II 2×1000MW ultra-supercritical coal-fired power unit project, the VIBRO-METER VM600 MPC4 was used in the turbine TSI monitoring system. The power plant uses N1000-26.25/600/600 type turbines jointly designed by Shanghai Turbine Co., Ltd. and Siemens, and the TSI system uses VM600 series products. The MPC4 card has a self-diagnostic function that can detect and display faults in sensors, preamplifiers, and extension cables. The module supports hot-swapping, significantly improving system reliability and maintenance convenience. This project was completed and put into operation in 2009, and the precise monitoring of the VM600 system effectively ensured the safe and stable operation of the turbines.

In an application at a newly built power plant in Shanxi, the VIBRO-METER VM600 MPC4 successfully resolved the problem of sawtooth-like fluctuations in the shaft vibration signal during turbine startup. Inspection revealed a grounding issue in the preamplifier, caused by an excessively long screw fixing the preamplifier, resulting in contact between the preamplifier and the junction box. After replacing the screw, the preamplifier was insulated from the junction box, the interference disappeared, and the signal returned to normal. This case fully demonstrates the high-precision measurement capabilities and anti-interference performance of the MPC4 card, as well as its reliability in complex industrial environments.

Parameter

Main Parameters

Value/Description

Product Model

VIBRO-METER VM600 MPC4

Manufacturer

Vibro-Meter (Meggitt)

Product Category

Mechanical Protection Card

Input Channels

4 dynamic channels + 2 speed channels

Frequency Range

0.5Hz to 10kHz

Measurement Range

0.1 mm/s to 50 mm/s

Accuracy

±0.05%FS (Full Scale)

Data Sampling Rate

256 samples per second

Operating Temperature

-20°C to 60°C

Storage Capacity

10,000 data points

Supply Voltage

24VDC

Dimensions

210 x 170 x 75 mm

Weight

1.5 kg

Protection Class

IP20

Signal Input

BNC connector

Communication Interface

RS-485 (supports Modbus RTU, Ethernet)

Safety Certification

SIL2 (Safety Integrity Level 2)

Hot-swappable Support

Yes

Relay Outputs

4 configurable relays (2 contacts each)

Technical Principles and Innovative Values

Innovation Point 1: Multi-channel Digital Signal Processing Technology

The VIBRO-METER VM600 MPC4 uses advanced DSP technology for real-time measurement and monitoring, capable of simultaneously processing 4 dynamic signals and 2 speed signals. Each dynamic channel has 2 processing outputs, and each speed channel has 1 processing output, supporting relative and absolute vibration measurement. The card has built-in programmable broadband and narrowband filters, which can simultaneously monitor amplitude and phase in order tracking mode, providing comprehensive data support for fault diagnosis.

Innovation Point 2: Highly Configurable Measurement Functions

The card supports various sensor types, including accelerometers, velocity sensors, and proximity probes, and can be configured to measure signals such as acceleration, velocity, and displacement (proximity). On-board multi-channel processing allows for the measurement of various physical parameters such as relative vibration, absolute vibration, Smax, eccentricity, thrust position, absolute and differential casing expansion, displacement, and dynamic pressure. This flexibility allows it to adapt to the monitoring needs of various industrial application scenarios.

Innovation Point 3: Safety Integrity Level Certification

The VIBRO-METER VM600 MPC4 is SIL2 safety certified, making it suitable for safety-critical applications. The card features user-programmable alarm, danger, and normal setpoints, supporting adaptive alarm level functionality. Each alarm level has an internal digital output that can drive four local relays on the IOC4T card, or relays on optional relay cards such as the RLC16 or IRC4 via the VM600 rack’s backplane bus, ensuring timely protective measures are taken in abnormal situations.

Innovation Point 4: Hot-Swappable and High-Reliability Design

The card supports real-time insertion and removal (hot-swappable), allowing for maintenance and replacement during system operation, significantly reducing downtime. The highly integrated card pair (with IOC4T) includes sensor power, buffered output, DC output, relays, and serial communication interfaces, providing a complete mechanical protection solution. Front panel BNC connectors facilitate analysis of buffered “raw” sensor signals, and front panel LEDs display status and alarms for easy on-site maintenance.

Innovation Point 5: Flexible Output Configuration

Processed dynamic (vibration) and velocity signals are available as analog output signals at the rear of the rack (on the front panel of the IOC4T), providing both voltage (0 to 10V) and current (4 to 20mA) signals. This flexible interface design facilitates integration with other control systems and supports Modbus RTU and Ethernet communication protocols for data exchange and remote monitoring.

Application Cases and Industry Value

Case Study: Ninghai Power Plant Phase II TSI System Application

Ninghai Power Plant Phase II’s 2×1000MW ultra-supercritical coal-fired units use the VIBRO-METER VM600 MPC4 as the core card for the turbine TSI monitoring system. The turbine used in this unit is the N1000-26.25/600/600 type, jointly designed by Shanghai Turbine Co., Ltd. and Siemens, and the TSI system uses VM600 series products. The MPC4 card features a self-test function that can detect and display faults in sensors, preamplifiers, extension cables, etc. The module supports hot-swapping, significantly improving system reliability and ease of maintenance. This project was completed and put into operation in 2009. Through the precise monitoring of the VM600 system, it effectively ensured the safe and stable operation of the steam turbine, preventing equipment damage and production losses caused by abnormal vibrations.

Case Study: Vibration Monitoring Optimization at a New Power Plant in Shanxi

In an application at a new power plant in Shanxi, the VIBRO-METER VM600 MPC4 successfully solved the problem of sawtooth-like fluctuations in the shaft vibration signal during turbine startup. Inspection revealed a grounding issue in the preamplifier, caused by an excessively long screw fixing the preamplifier, resulting in contact between the preamplifier and the junction box. After replacing the screw, the preamplifier was insulated from the junction box, the interference disappeared, and the signal returned to normal. This case fully demonstrates the high-precision measurement capabilities and anti-interference performance of the MPC4 card, as well as its reliability in complex industrial environments. This solution prevented false alarms and shutdowns caused by signal interference, ensuring the stable operation of the power plant.

Related Product Combination Solutions

VIBRO-METER VM600 IOC4T

The IOC4T is the input/output interface card for the MPC4 card, installed at the rear of the VM600 ABE04x rack, forming a card pair with the MPC4 card. The IOC4T card supports 4 dynamic channels and 2 tachometer (speed) channels, each with differential signal input and sensor power output, providing buffered output, DC output, relays, and a serial communication interface.

VIBRO-METER VM600 ABE040

The ABE040 is a 19-inch 6U high frame for the VM600 system, using an aluminum structure and supporting a modular design. The front of the frame houses processing cards such as CPUM/MPC4/AMC8/XMC16 and the RPS6U power supply, while the rear houses IO and relay cards such as IOCN/IOC4T/IOC8T/XIO16T/RLC16/IRC4. The frame contains an integrated VME backplane bus and supports redundant power supply. VIBRO-METER VM600 RPS6U

The RPS6U is the power supply module for the VM600 system, providing power to other cards in the rack. It supports single or redundant power supply; in redundant mode, each power supply carries 50% of the load, and if one fails, the other switches to 100%. The power supply module has a power failure alarm function to ensure the reliability of the system power supply.

VIBRO-METER VM600 RLC16

The RLC16 is the relay card for the VM600 system, providing additional relays driven by signals from the MPC4 and/or AMC8 cards when the four relays on the IOC4T and IOC8T cards are insufficient. This card contains 16 SPDT relays, which are hardware configurable and can be configured for normally energized (NE) or normally de-energized (NDE) operation.

VIBRO-METER VM600 CPUM

The CPUM is the CPU module of the VM600 system, responsible for system data processing and control logic execution. This module supports various communication protocols, including Modbus RTU, Ethernet, etc., enabling data exchange and remote monitoring with the host system.

VIBRO-METER VM600 XMV16

The XMV16 is a multi-channel vibration monitoring module for the VM600 system, supporting 16 dynamic channels, suitable for vibration monitoring of large rotating machinery. This module uses advanced DSP technology to provide high-precision vibration measurement and analysis functions.

VIBRO-METER VM600 XIO16T

The XIO16T is an input/output card for the VM600 system, supporting 16 dynamic channels and providing sensor power, buffered output, DC output, relays, and serial communication interfaces. This card is used in conjunction with the XMV16 module to form a complete vibration monitoring solution.

Installation, Maintenance, and Full-Cycle Support

Installation and Commissioning

The VIBRO-METER VM600 MPC4 is installed in the front of the VM600 ABE04x rack, requiring the IOC4T card to be installed in the rear of the rack to form a card pair. Before installation, ensure that the rack power is disconnected. Insert the MPC4 card into the front slot of the rack and the IOC4T card into the corresponding slot in the rear. Connect the sensor signal lines and power lines, ensuring the connections are correct and secure. After powering on, configure the system using the VM600 MPSx software, setting channel parameters, alarm thresholds, and communication parameters. After configuration, perform functional testing to verify that signal acquisition, alarm output, and communication functions are working correctly.

Routine Maintenance and Troubleshooting

Regularly check the status indicators of the MPC4 card to ensure all channels are working properly. Regularly clean dust from the card surface and check for loose connectors. Use the VM600 MPSx software to view historical data and alarm records to analyze the equipment’s operating status. In case of a malfunction, first check that the sensors, preamplifiers, and cable connections are working correctly, and then use the software’s diagnostic functions to pinpoint the problem. The MPC4 card supports hot-swapping, allowing for replacement of faulty cards while the system is running, minimizing downtime.

Technical Support and Service Commitment

VIBRO-METER provides comprehensive technical support and services, including installation guidance, configuration consulting, fault diagnosis, and repair services. Detailed user manuals and technical documentation are provided to help users quickly master product usage. For urgent faults, a rapid response service is provided to ensure timely system recovery. Regular software updates and functional upgrades are provided to keep the system in optimal condition.

Contact us for a customized solution tailored to your specific industrial automation requirements.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: