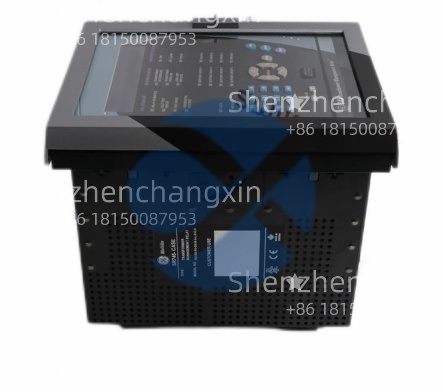

The GE CT11T7F10PN1 PMC676RCTX V2.3 01 16 C1145 CR11 V2.X is a high-performance embedded control module manufactured by General Electric (GE), designed specifically for industrial automation control systems. This module utilizes an advanced 32-bit ARM Cortex processor, equipped with 128MB of SDRAM and 8MB of Flash memory, supporting multiple programming languages and communication protocols, making it suitable for complex industrial control tasks.

Key Features

High-Performance Processing Capability: The module features an ARM Cortex processor with powerful data processing capabilities, meeting the demands of complex control algorithms. The 128MB SDRAM and 8MB Flash memory configuration ensures smooth and stable system operation.

Rich Communication Interfaces: Equipped with multiple interfaces including serial port, Ethernet, and USB, supporting various communication protocols such as TCP/IP, Modbus, and DNP3. The Ethernet interface provides two 10/100/1000BaseT full-duplex ports, supporting RJ-45 TX connectors, and some versions also offer fiber optic SC or LC interfaces (PMC676RCSC).

Wide Operating Temperature Range: With an operating temperature range of -40°C to +85°C, it can operate stably in harsh industrial environments, suitable for various demanding applications.

Standard Compatibility: Compliant with the IEC61131-3 standard, supporting multiple programming languages, including graphical KOP/FUB and text-based AWL or ST, and integrating CApen functionality for use as intelligent, distributed control nodes.

Technical Specifications

Parameter

Specification

Processor

ARM Cortex

Memory

128MB SDRAM + 8MB Flash

Operating Temperature

-40°C to +85°C

Dimensions

75mm × 149mm

Communication Interfaces

Serial port, Ethernet, USB

Ethernet Ports

2 × 10/100/1000BaseT full-duplex

Communication Protocols

TCP/IP, Modbus, DNP3

Power Supply Voltage

24V DC

Power Consumption

Maximum 10W

Application Areas

This module is widely used in automation control systems in power, petrochemical, manufacturing, transportation infrastructure, and other fields. As a core component of the control system, it is responsible for collecting, processing, and analyzing input signals, and outputting control signals according to preset control logic to achieve precise control of industrial equipment or systems. It can monitor and control key parameters such as temperature, pressure, flow rate, and liquid level in the production process, ensuring the stability and safety of the production process.

Typical application scenarios:

Power generation and distribution automation systems

Petrochemical process control

Manufacturing production line automation

Transportation infrastructure monitoring

Water treatment and environmental protection systems

System integration

The module uses the OpenPCS programming system, offering flexible and diverse programming methods, supporting both graphical and text-based programming. Integrated CApen functionality allows it to function as an intelligent, distributed control node, enabling interconnectedness in factory automation. The module’s compact size (75mm × 149mm) allows for installation and use in space-constrained equipment, facilitating system integration and maintenance.

This module is part of GE’s product series and can work in conjunction with other GE automation products to meet the needs of control systems of varying sizes and complexities. Its high reliability and stability make it a preferred solution in the field of industrial automation.

Choose Shenzhen Changxin, choose peace of mind, worry-free after-sales service! Large stock available, same-day SF Express shipping!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: