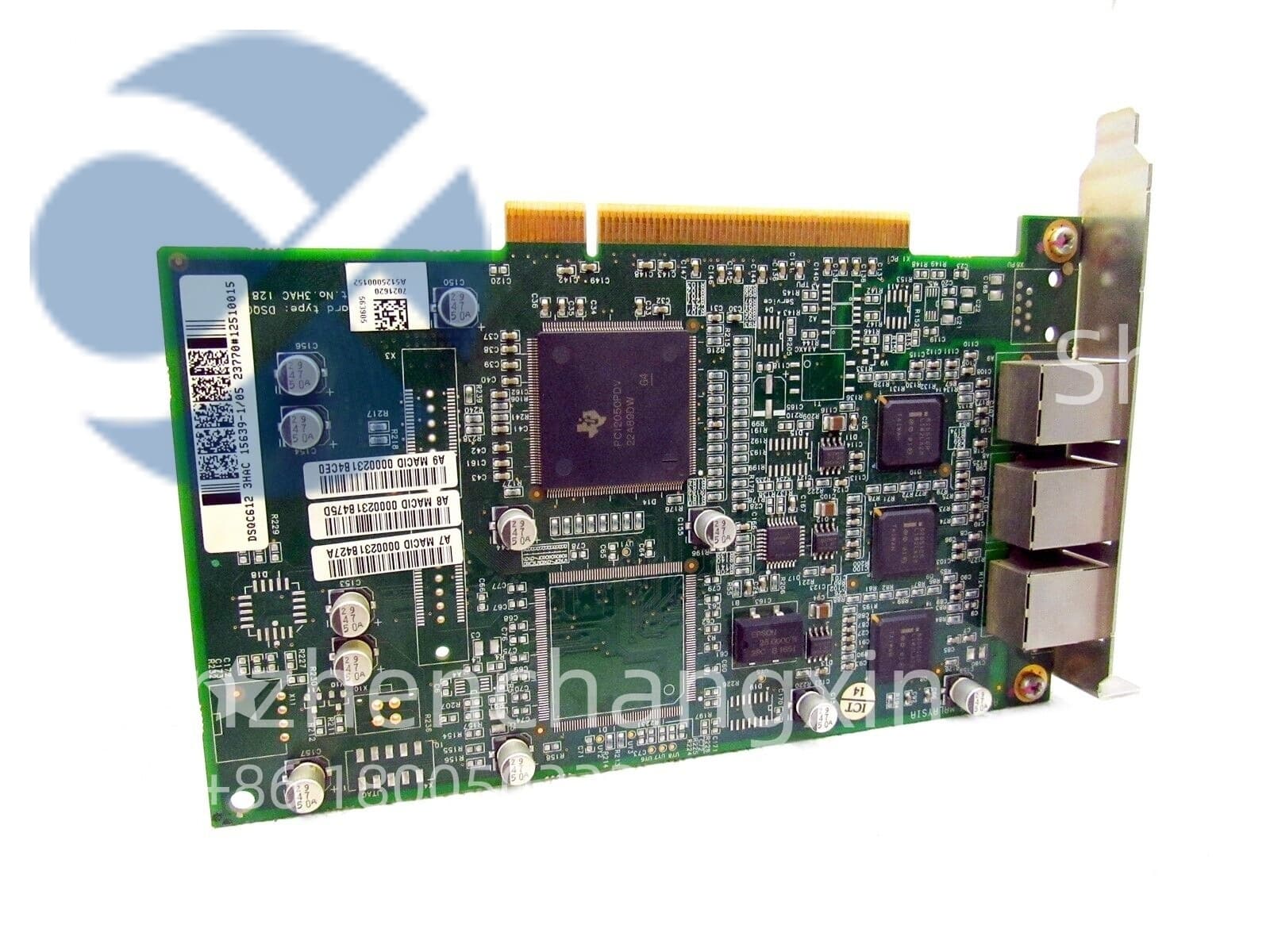

Product Description

The ABB 3HAC10847-1is a specialized Drive Module within the ABB IRC5 robot controller system,designed to control a specific axis servo motor on heavy-payload robots like the IRB 7600 series.It functions as the intelligent power interface,converting DC bus power into precisely controlled 3-phase AC to drive the brushless servo motor,managing torque,speed,and position for a single robot joint.This module is a critical component for the precise,powerful,and dynamic motion required in material handling,spot welding,and machine tending applications.

Application Scenario

In a large automotive stamping press line,a heavy-duty ABB IRB 7600 robot is responsible for transferring massive sheet metal blanks.The robot’s wrist axis(Axis 5),controlled by the ABB 3HAC10847-1drive module,must maintain precise orientation of the 200kg blank as the robot swings it at high speed.During a transfer,a misaligned blank caused a momentary,violent jolt as it contacted the die.The servo motor on Axis 5 experienced a massive instantaneous torque spike.The 3HAC10847-1module’s integrated dynamic safety functions reacted in microseconds.Its advanced monitoring circuits detected the motor phase current exceeding the safe operating area(SOA)and initiated a hardware-level current limitation.Simultaneously,it sent a high-priority”Motor Overload”fault via the Drive Module Link(DML)to the main controller,triggering a controlled emergency stop.This rapid,hardware-enforced protection prevented damage to the motor windings,the wrist gearbox,and potentially the entire robot arm structure.The event was logged with detailed axis data,allowing engineers to pinpoint the collision cause.This demonstrates the module’s dual role:providing the robust power needed for heavy payloads while embedding fail-safe protection that safeguards the robot’s most expensive mechanical components from catastrophic overload damage.

Key Parameters

Main Parameters

Value/Description

Product Model

ABB 3HAC10847-1

Manufacturer

ABB Robotics

Product Category

Robot Servo Drive Module/Axis Drive

Compatible System

ABB IRC5 Robot Controller(for specific robot types like IRB 7600)

Control Function

Single-axis servo drive control,typically for a specific robot axis.

Power Stage

High-power IGBT-based inverter for 3-phase motor control.

Communication

Connected via the internal high-speed serial link(Drive Module Link-DML)to the main computer.

Protection Features

Over-current,over-temperature,short-circuit,ground fault,IGBT de-saturation detection.

Feedback Interface

Connects to the motor’s resolver or encoder for closed-loop position/torque control.

Cooling

Designed for integration into the controller’s forced-air or liquid cooling system.

Technical Principles and Innovative Values

High-Power Density IGBT Inverter for Demanding Loads:The 3HAC10847-1is built around a robust Insulated Gate Bipolar Transistor(IGBT)power stage,specifically sized for the high torque and speed requirements of a heavy-payload robot axis.It utilizes advanced switching patterns and thermal management to deliver high continuous and peak current output efficiently.This high power density allows the robot to achieve rapid accelerations and handle substantial inertial loads without overheating,which is fundamental to the productivity of applications like press-to-press transfer.

Advanced Motor Control with Dual-Loop Feedback:The module executes sophisticated servo control algorithms.It uses two critical feedback loops:1)An inner high-speed current(torque)loop,closed via internal shunt resistors,ensuring the motor delivers the exact instantaneous torque commanded.2)An outer position/speed loop,closed via the absolute encoder(resolver)feedback from the motor.The drive processes this data to commutate the motor accurately.This precise,multi-loop control,managed locally on the 3HAC10847-1,is what gives ABB robots their characteristic smooth,accurate,and powerful motion,even under variable loads.

Integrated Safety and Condition Monitoring:Safety and diagnostics are engineered into the module’s hardware.Beyond basic electrical protections,it monitors the health of the IGBTs,DC link voltage,and its own temperature.More importantly,it can detect abnormal motor conditions indicative of mechanical problems,such as excessive ripple current suggesting bearing wear or uneven load distribution.This diagnostic data is streamed to the main controller for predictive maintenance analysis,transforming the drive from a simple power amplifier into a key source of machine health intelligence.

Application Cases and Industry Value

Case Study:Foundry Furnace Tapping and Pouring Robot

A ferrous foundry uses an ABB IRB 7600 robot,equipped with a special end-effector,to tap a furnace and pour molten iron into molds.The environment is extreme,with radiant heat and conductive dust.The robot’s Axis 3(lower arm)drive module,a 3HAC10847-1,operates continuously under high static load to support the heavy ladle.After 18 months,the robot began to exhibit slight”juddering”during precise pour motions.Diagnostics from the robot controller traced subtle torque irregularities to the Axis 3 drive.The foundry’s maintenance team replaced the 3HAC10847-1module.The chief engineer reported:”The drive’s diagnostics were incredibly precise.They didn’t just say’fault’;they indicated a specific IGBT gate driver anomaly that correlated with the judder.Replacing the module restored perfect motion.The critical insight is that the module failed safely—it didn’t overheat and burn out,which could have taken the motor with it.In this application,a robot failure during a pour would be catastrophic.The drive’s reliability and protective design are absolutely vital to our operation’s safety and continuity.”This underscores the module’s value in the most severe industrial applications:its robustness ensures uptime,while its intelligent failure modes and diagnostics protect downstream assets and enable proactive maintenance,safeguarding both personnel and production.

Related Product Combination Solutions

The ABB 3HAC10847-1functions within a tightly integrated robotic motion system:

IRC5 Main Computer(e.g.,DSQC1000):The central processor that calculates robot paths and sends torque references to all axis drives,including the 3HAC10847-1,via the DML.

Robot Servo Motor(for the specific axis):The high-torque,low-inertia synchronous motor that the drive module controls.The motor and drive are a matched pair.

Resolver/Encoder Feedback Cable:The critical link that carries the motor’s absolute position signal back to the drive module and main computer.Its integrity is essential for safe operation.

IRC5 Drive Module Rack&Power Supply:The chassis that houses the 3HAC10847-1and other axis drives,and the high-power DC supply that feeds them.

Brake Chopper&Resistor Unit:Manages the regenerative energy generated when the heavy axis decelerates,which is fed back to the DC bus.The 3HAC10847-1coordinates with this system.

Robot Teach Pendant(FlexPendant):Used to jog the robot,view detailed drive and axis fault messages,and access maintenance counters and logs for the 3HAC10847-1.

Installation,Maintenance,and Full-Cycle Support

Replacement of the ABB 3HAC10847-1is a high-precision task that must be performed by certified personneldue to lethal voltages and the risk of uncontrolled motion.The procedure involves a full controller lockout,discharge of DC link capacitors,module replacement,and—most critically—a mandatory recalibration of the robot’s absolute encoder system(RevCounter update)using the proper service routines.Skipping recalibration can cause the robot to move violently to an incorrect position.

Routine maintenance involves ensuring the controller cabinet cooling system is functional and monitoring drive temperatures and logged warnings via the service interface.Our support provides genuine,factory-tested ABB 3HAC10847-1drive modules.We verify compatibility with your specific IRB robot type and controller hardware revision.We emphasize the critical safety requirement for recalibrationand can provide links to necessary documentation.We are committed to being a reliable source for these critical components and the essential safety knowledge required for their proper integration.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: